Semiconductor structure and forming method thereof

A technology of semiconductors and conductive layers, which is applied in the manufacture/processing of components of electromagnetic equipment, resistors controlled by magnetic fields, and electromagnetic devices, and can solve problems such as poor performance of magnetic random access memory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] As mentioned in the background, currently formed semiconductor structures perform poorly.

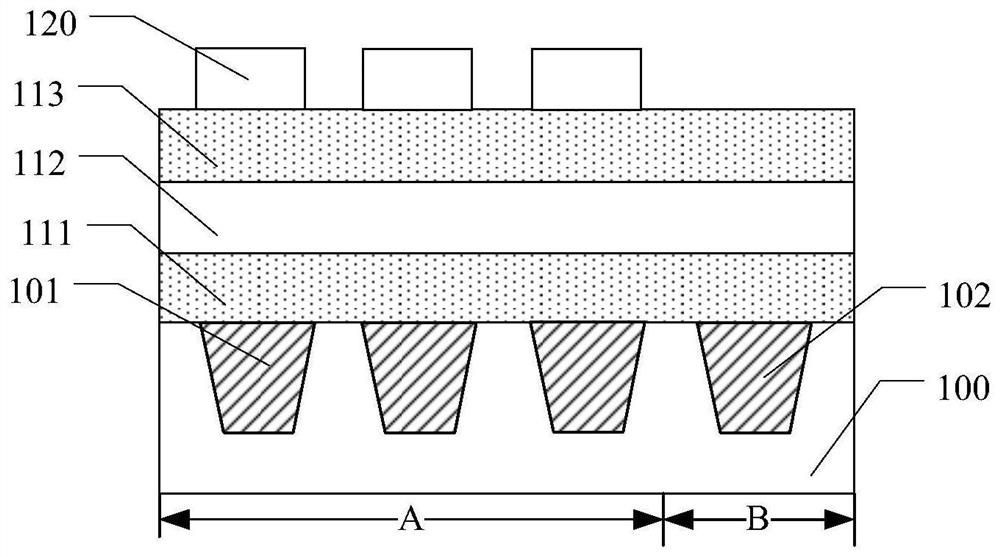

[0032] The reasons for the poor performance of the semiconductor structure will be described in detail below in conjunction with the accompanying drawings. Figure 1 to Figure 6 It is a structural schematic diagram of each step of a method for forming a semiconductor structure.

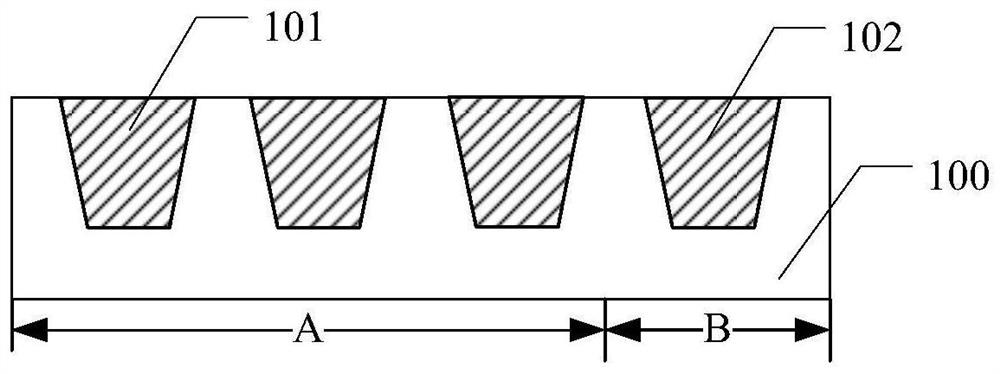

[0033] Please refer to figure 1 , providing a substrate 100, the substrate 100 includes a storage area A and a logic area B, the storage area A has a first conductive layer 101, the logic area B has a second conductive layer 102, and the substrate 100 is exposed The top surface of the first conductive layer 101 and the top surface of the second conductive layer 102 are shown.

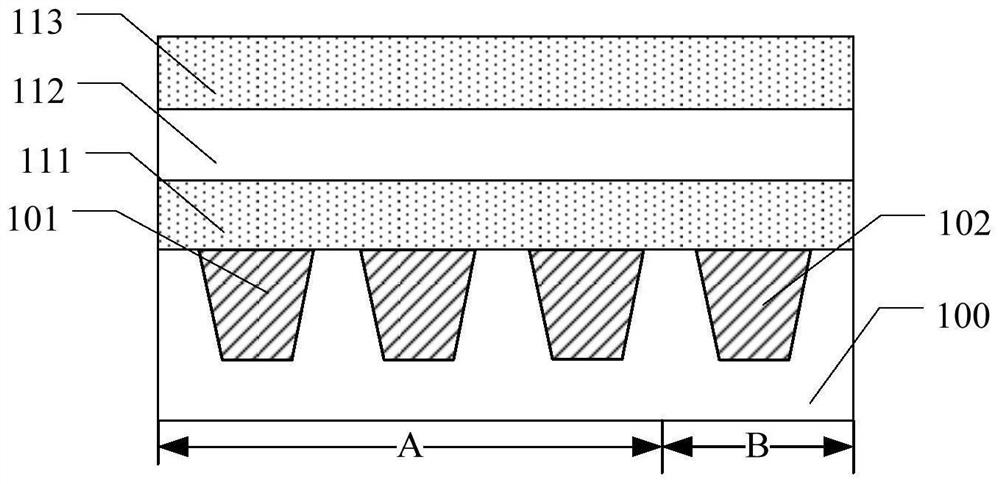

[0034] Please refer to figure 2 , forming a first electrode film 111 , a magnetic tunnel film 112 on the surface of the first electrode film 111 , and a second electrode film 113 on the surface of the magnetic tunnel film 112 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com