Preparation method and packaging process of sealing glass material for lithium-manganese dioxide battery cover group

A manganese dioxide, sealing glass technology, applied in the direction of sealing materials, etc., can solve the problems of battery life and performance limitations, easy battery leakage, poor resistance to electrolyte corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method for the sealing glass material of lithium-manganese dioxide battery cover group comprises the following steps:

[0042] 1), select raw materials according to the following molar percentages:

[0043] SiO 2 : 40%~60%,

[0044] B 2 o 3 : 5%~25%,

[0045] Al 2 o 3 : 0%~5%,

[0046] BaO: 5% to 15%,

[0047] Na 2 O: 5% to 15%,

[0048] K 2 O: 0% to 5%,

[0049] MgO: 0% to 5%,

[0050] CaO: 0% to 5%,

[0051] TiO 2 : 0%~5%,

[0052] ZrO 2 : 0%~5%,

[0053] ZnO: 0% to 5%,

[0054] Cr 2 o 3 : 0%~5%,

[0055] Among them, various oxides should include various salts and acid-base compounds;

[0056] 2) Prepare the above-mentioned raw materials and place them in an ultra-high-speed disperser for mixing and dispersing, so that various raw materials can be mixed and dispersed evenly;

[0057] 3) Put the uniformly mixed materials in the crucible, place the crucible in a silicon-molybdenum furnace, and raise the temperature from room temperat...

Embodiment 1

[0070] 1), a sealing glass material for lithium-manganese dioxide battery cover group, prepared from the following raw materials in terms of molar mass ratio: SiO 2 : 40%, B 2 o 3 : 25%, Al 2 o 3 : 3%, BaO: 8%, Na 2 O: 11%, K 2 O: 3%, MgO: 3%, CaO: 3%, TiO 2 : 1%, ZrO 2 : 1%, ZnO: 2%.

[0071] 2) Prepare the above-mentioned raw materials and place them in an ultra-high-speed disperser for mixing and dispersing, so that various raw materials can be mixed and dispersed evenly;

[0072] 3) Put the uniformly mixed materials in the crucible, place the crucible in a silicon-molybdenum furnace, and raise the temperature from room temperature to 300-600°C at a rate of 8-10°C / min in an air atmosphere, and at 300-600°C Keep warm for 30-60 minutes to promote the decomposition of various salts and acid-base compounds, then raise the temperature to 1500-1700°C at a rate of 8-10°C / min, and keep warm at 1500-1700°C for 1-2 hours; stir several times during the period , make the melti...

Embodiment 2

[0080] 1), a sealing glass material for lithium-manganese dioxide battery cover group, prepared from the following raw materials in terms of molar mass ratio: SiO 2 : 45%, B 2 o 3 : 20%, Al 2 o 3 : 3%, BaO: 8%, Na 2 O: 11%, K 2 O: 3%, MgO: 3%, CaO: 3%, TiO 2 : 1%, ZrO 2 : 1%, ZnO: 2%.

[0081] 2) Prepare the above-mentioned raw materials and place them in an ultra-high-speed disperser for mixing and dispersing, so that various raw materials can be mixed and dispersed evenly;

[0082] 3) Put the uniformly mixed materials in the crucible, place the crucible in a silicon-molybdenum furnace, and raise the temperature from room temperature to 300-600°C at a rate of 8-10°C / min in an air atmosphere, and at 300-600°C Keep warm for 30-60 minutes to promote the decomposition of various salts and acid-base compounds, then raise the temperature to 1500-1700°C at a rate of 8-10°C / min, and keep warm at 1500-1700°C for 1-2 hours; stir several times during the period , make the melti...

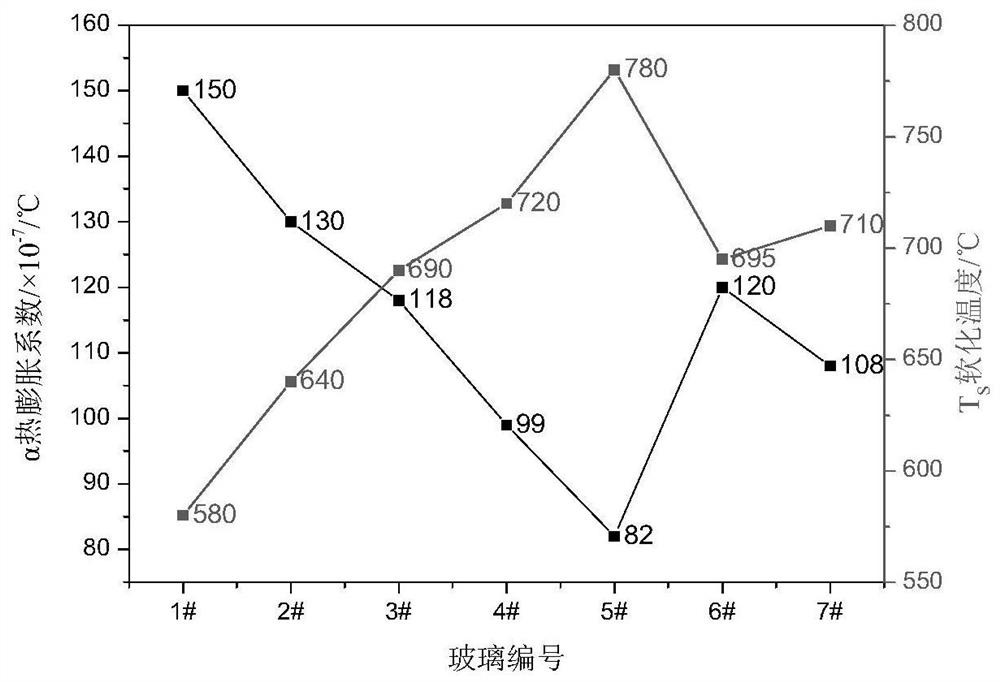

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com