Anti-cracking asphalt concrete and preparation method thereof

An anti-cracking technology for asphalt concrete, applied in the field of asphalt concrete, can solve problems such as the decrease of pavement structural bearing capacity and increase the degree of cracking of the pavement, and achieve the effect of reducing the degree of cracking and improving the anti-cracking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

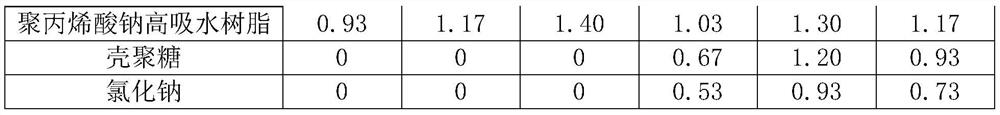

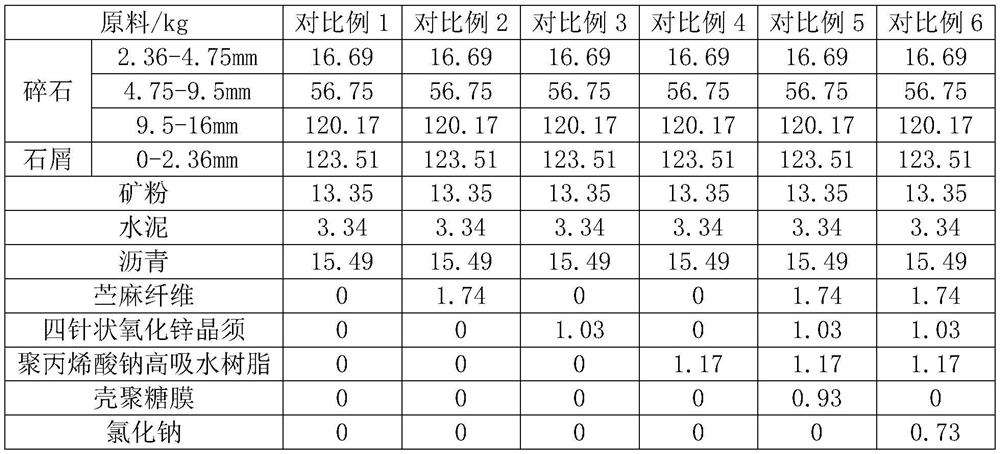

preparation example 1

[0041]0.67 kg of chitosan was dissolved in 2% acetic acid aqueous solution, and the ratio of chitosan to acetic acid aqueous solution was 5 g: 200 ml. Stir until the chitosan is completely dissolved, then perform ultrasonic defoaming treatment on the solution until the bubbles completely disappear, and prepare a chitosan film-forming liquid for future use.

preparation example 2

[0043] The difference between this preparation example and preparation example 1 is: the weight of chitosan is 1.2kg.

preparation example 3

[0045] The difference between this preparation example and preparation example 1 is: the weight of chitosan is 0.93kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com