A kind of TA-C base multilayer wear-resistant cutting tool coating and preparation method thereof

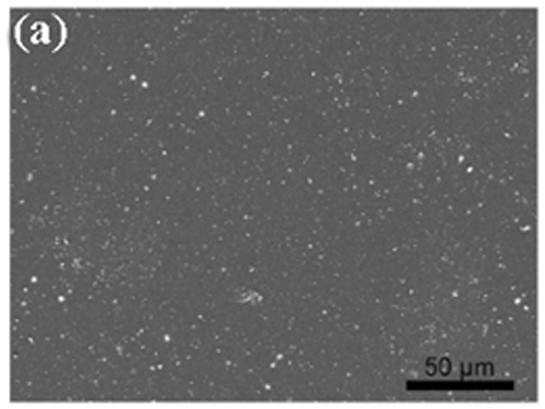

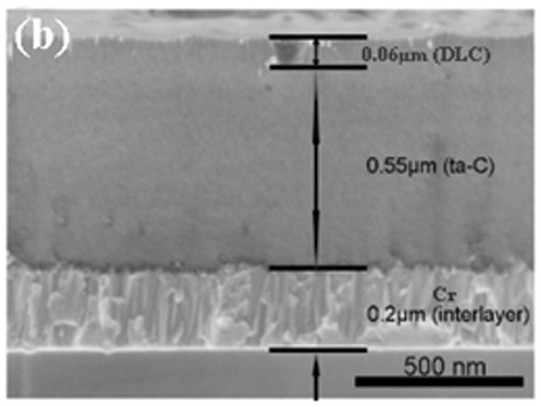

A ta-c, wear-resistant layer technology, applied in the field of tetrahedral amorphous carbon (ta-c) based composite tool coating and its preparation, can solve the problems of stress concentration at the interface, easy peeling failure, etc., to reduce the film Base stress concentration, reducing the distribution of large particles on the surface, and the effect of dense and smooth coating surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) A commercially purchased YG6 tungsten carbide tool was used as a sample (tool material composition, WC: 94wt.%, Co: 6wt.%, hardness HRA89); the samples were ultrasonically cleaned with acetone and anhydrous ethanol for 20 min, and removed Surface oil and its oxides;

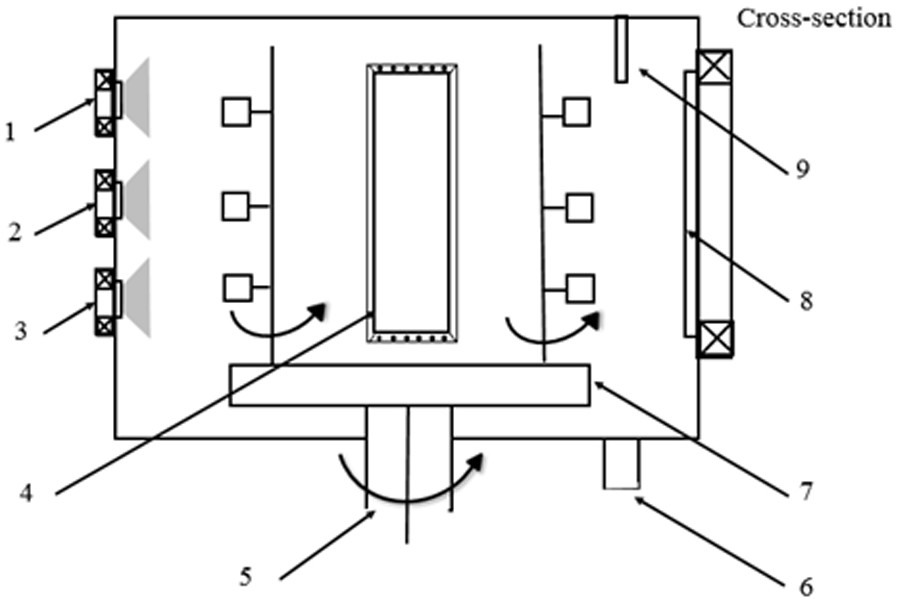

[0035] (2) Use a vacuum cleaner to absorb the impurity particles and fine dust in the vacuum chamber, place the tool holder on the turret, turn on the vacuum unit, and wait until the vacuum degree of the chamber reaches 3.0×10 -3 When Pa, the magnetron rectangular Cr target was turned on, the target power was adjusted to 200W, and the sputtering was performed for 10min. This step can eliminate the influence of the excess charge in the cavity and the contamination of the fixture surface causing the poor film quality;

[0036] (3) Ion etching cleaning of the sample: the tool sample is supported on the turret 7, and the vacuum degree of the cavity is pumped to 3.0×10 - 3 Pa, the rotation speed of the s...

Embodiment 2

[0042] (1) Purchase commercial micro-drills with different grades of cutting diameter, and use petroleum ether, acetone, and anhydrous ethanol for ultrasonic cleaning for 10 minutes in turn. After sonication, the sample was taken out and purged with dry nitrogen;

[0043] (2) Use a high-power vacuum cleaner to clean up particulate impurities, target surface pollutants, and sample turret impurities in the cavity, place the tool holder on the turret, turn on the vacuum unit, and wait until the cavity vacuum reaches 3.0×10 -3 When Pa, turn on the magnetron rectangular Cr target, adjust the target power to 200W, and sputter for 10 minutes;

[0044] (3) Put the cleaned micro-drill into the clamping set, and vacuum the cavity bottom to 3.0×10 -3 Below Pa, the temperature is set to 150°C, then 100sccm / min argon gas is passed into the cavity, the bias voltage is -300V, and the glow discharge of Ar ions is used for cleaning for 30min;

[0045] (4) Preparation of substrate bonding lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com