Method for preparing MOF (at) MOF hybrid membrane by using two-dimensional nanosheet membrane induced heteroepitaxial growth method

A heteroepitaxy, two-dimensional nanotechnology, applied in chemical instruments and methods, separation methods, membrane technology, etc., to achieve excellent molecular sieving performance, simple and efficient preparation method, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

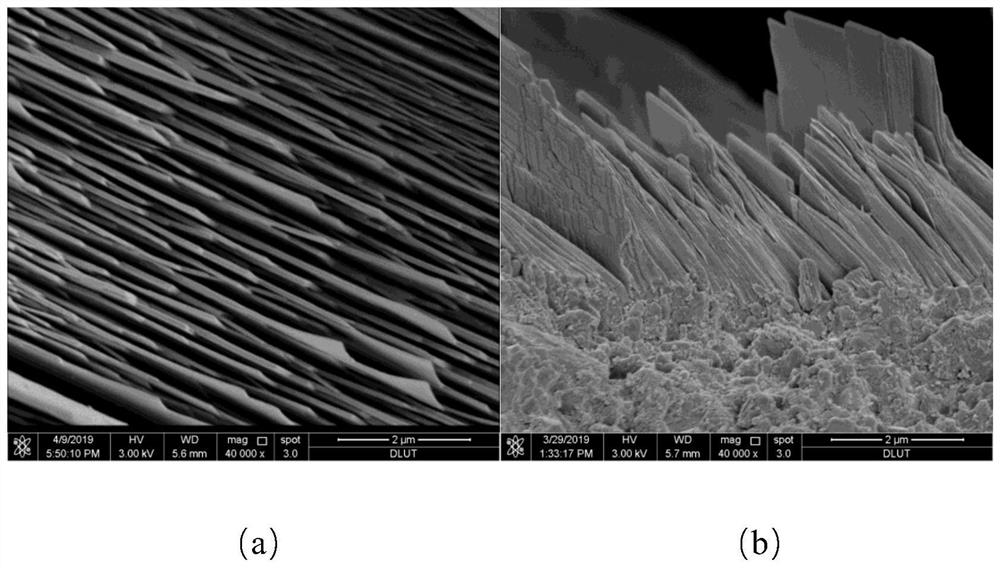

Image

Examples

Embodiment 1

[0023] A method for preparing a MOF@MOF hybrid film by using a two-dimensional nanosheet film-induced heteroepitaxial growth method;

[0024] Step (1): An alumina porous ceramic tube with an average pore diameter of 200 nm was selected as a carrier, ultrasonically cleaned with absolute ethanol for 30 min before use, and then dried in a vacuum oven at 80° C. for 1 h.

[0025] Step (2): Mix 8.2624g of zinc acetate and 50mL of ethylene glycol methyl ether, and stir in a water bath at 70°C for 30min, then slowly add 4.6mL of ethanolamine dropwise, and stir at room temperature for 24h to obtain a zinc sol, and then in the porous The zinc sol was pulled three times on the surface of the ceramic tube, dried in an oven at 100°C for 1 hour after each pull, and finally calcined in a muffle furnace at 400°C for 200 minutes to obtain a carrier with an active layer of ZnO nanoparticles.

[0026] Step (3): The carrier with the ZnO nanoparticle active layer obtained in step (2) is placed in ...

Embodiment 2

[0029] A method for preparing a MOF@MOF hybrid film by using a two-dimensional nanosheet film-induced heteroepitaxial growth method;

[0030] Step (1), step (2) and step (3) are the same as embodiment 1.

[0031] Step (4): with two-dimensional Zn obtained in step (3) 2 (bIm) 4 The carrier of the nanosheet film layer is placed in the ZIF-67 synthesis solution, and its molar ratio is specifically cobalt nitrate: dimethylimidazole: deionized water molar ratio of 1:75:6000. The synthesis temperature is 100°C, and the synthesis time is 12h. After the reaction, the ceramic tube carrier was taken out, and the surface of the membrane layer was gently washed with methanol, and then dried in a vacuum oven at 60°C for 12 hours to obtain Zn 2 (bIm) 4 @ZIF-67 hybrid membrane.

Embodiment 3

[0033] A method for preparing a MOF@MOF hybrid film by using a two-dimensional nanosheet film-induced heteroepitaxial growth method;

[0034] Step (1), step (2) and step (3) are the same as embodiment 1.

[0035] Step (4): with two-dimensional Zn obtained in step (3) 2 (bIm) 4 The carrier of the nanosheet film layer is placed in the Zn / Co-ZIF synthesis solution, and the molar ratio is specifically zinc nitrate: cobalt nitrate: dimethylimidazole: deionized water molar ratio is 0.5:0.5:75:6000. The synthesis temperature is 100°C, and the synthesis time is 12h. After the reaction, the ceramic tube carrier was taken out, and the surface of the membrane layer was gently washed with methanol, and then dried in a vacuum oven at 60°C for 12 hours to obtain Zn 2 (bIm) 4 @Zn / Co-ZIF hybrid film.

[0036] To the Zn prepared in the embodiment of the present invention 1 2 (bIm) 4 The @ZIF-8 hybrid membrane was tested for gas separation, and its H 2 / CO 2 、H 2 / N 2 、H 2 / CH 4 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com