Production equipment and production method of ethyl acetate

A technology of ethyl acetate and production equipment, which is applied in the field of ethyl acetate production, and can solve the problems of large consumption of cooling capacity, affecting the yield of ethyl acetate, loss of ethanol and ethyl acetate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] Embodiment 1: In this embodiment, the position of the collection port of the circulating reaction fluid is indicated by the readings on the axial movement drive mechanism and the rotation drive mechanism, which are respectively: 10 cm in the axial direction and 120° in the radial direction. The data is based on the corresponding starting position, and the specific starting position will be described in the following steps.

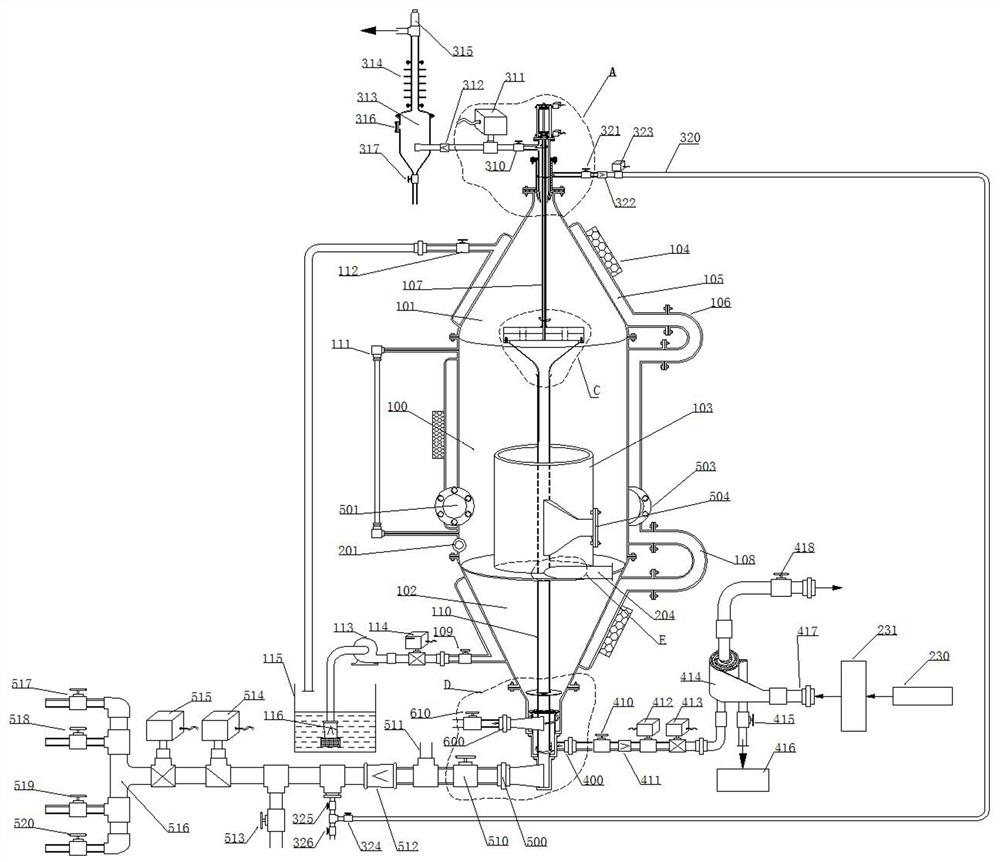

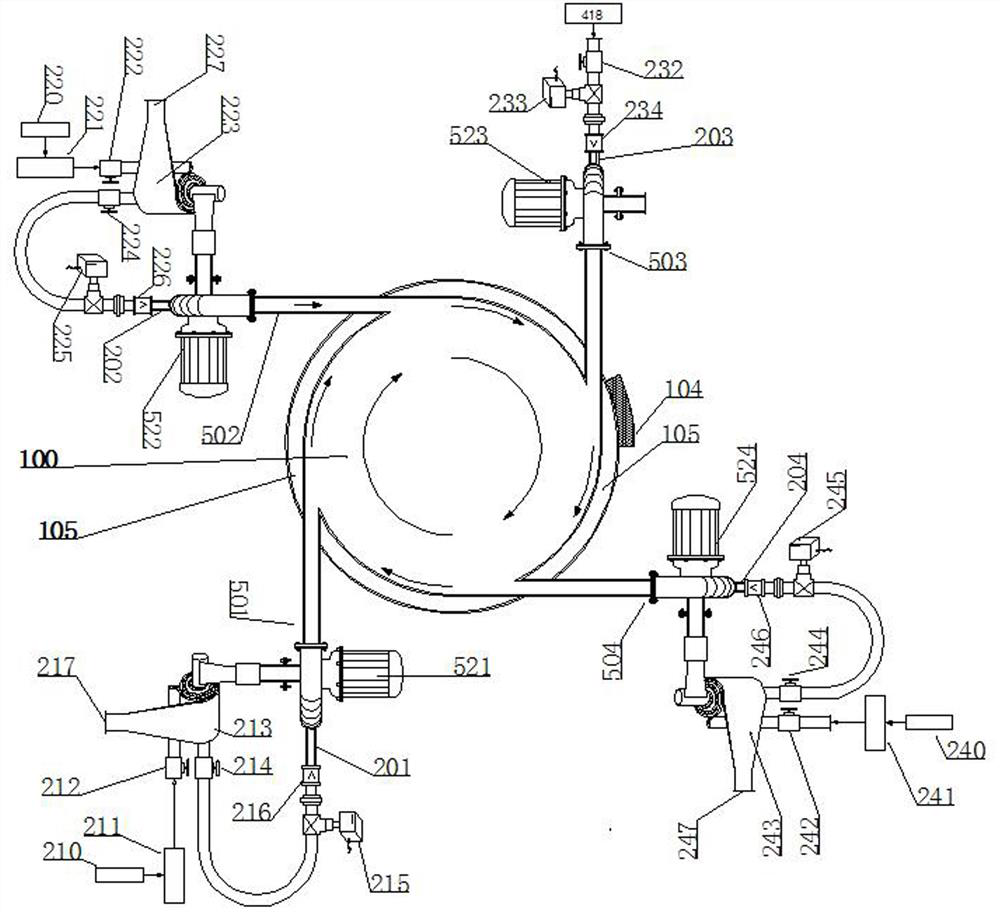

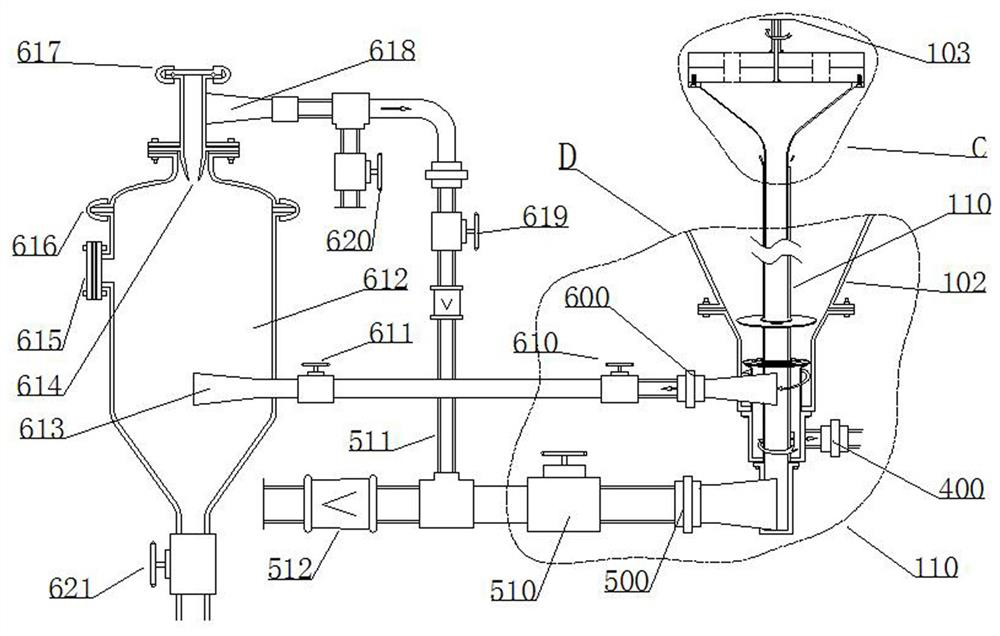

[0128] 1. Equipment selection

[0129] 1. Key data of split tank: the diameter of cylindrical section 100 is 3m, the height is 0.75m, the height of upper circular platform section 101 is 0.9m, the height of lower circular platform section 102 is 0.6m, and the volume of divided tank is 8.84m3. The diameter of the water vapor collection port 331 is 9.84cm, the diameter of the acetaldehyde vapor collection port 332 is 15.21cm, the diameter of the first blocking disk 904 is 49.05cm, the width of the first collection slit 907 is 3.24cm, and the diameter ...

Embodiment 2

[0170] Embodiment 2: Compared with Embodiment 1, the calculation method of reaction temperature, pressure, raw material ratio after realizing continuous reaction, operation process, spatial position of circulating reaction fluid collection port, material balance and kinetic energy balance in this embodiment, And gas chromatographic analysis method is all identical with the best state of embodiment 1, and difference is that the total input amount of acetaldehyde increases to 6.4kg / min by 6.00kg / min, and need not refill catalyst ethyl ester solution. Correspondingly, the measuring and controlling instrument of the material flow and the measuring and controlling instrument of the cooling water are reset as follows.

[0171] 1. The ratio of reactants to products

[0172] Anhydrous acetaldehyde (97%) 6.40kg / min

[0173] Ethyl acetate (≥99%) 6.21kg / min

[0174] Acetal (95±0.2%) 0.166kg / min

[0175] 2. According to the proportion of step 1, divide the total flow of acetaldehyde in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com