Mesoporous carbon nitride hollow microspheres and preparation method thereof

A mesoporous and hollow technology, applied in nitrogen and non-metallic compounds, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex preparation process of template agent, long reaction route and harsh reaction conditions, etc. Achieve high practical value, change the length of the reaction route, and simplify the preparation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] To 350 mL of deionized water was added 19.6 g of solid cetyltrimethylammonium bromide (CTABr) and 10 g of solid Na 2 SiO 3 , magnetically stirred at 30°C until completely dissolved to obtain a clear solution. Then 35 mL of ethyl acetate was added to the above solution, the mixture was magnetically stirred for 30 s, and left standing at room temperature for 5 h. Then, the reactor was sealed and placed in an oil bath at 90 °C for 50 h. After the reaction, the obtained precipitate is centrifuged and washed three times with water and ethanol respectively, and dried in the air to obtain the silica template agent.

[0018] Mix 8.5g of solid cyanamide with 1.5g of absolute ethanol, stir in a 60°C water bath at 400rpm for 2 minutes, and sonicate for 10min to obtain a clear and uniform cyanamide / ethanol solution, in which the mass fraction of cyanamide is 85%.

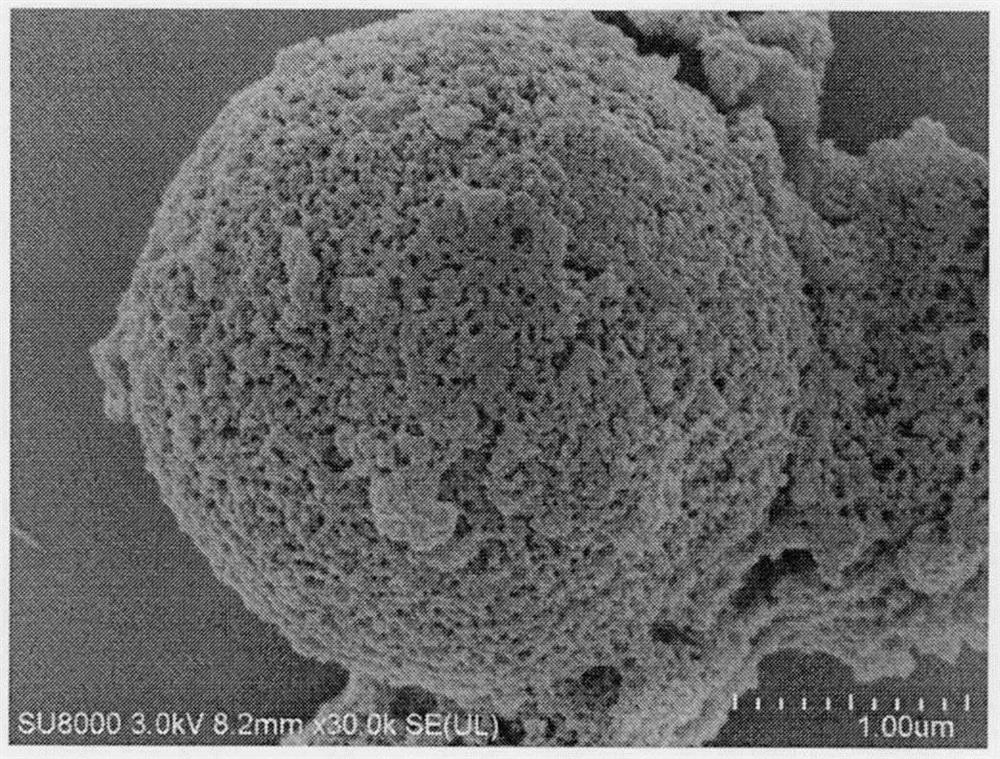

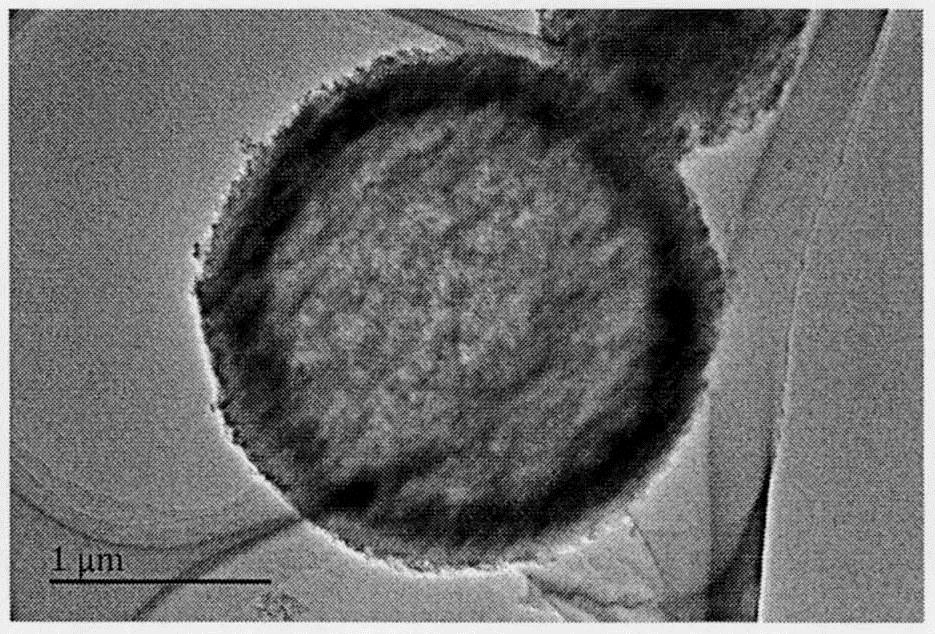

[0019] Take 0.5g SiO 2 The template was placed in a vacuum drying oven, vacuumed for 3.5 hours, added to the cyana...

Embodiment 2

[0021]The preparation process of this example is the same as that of Example 1, except that the amount of cetyltrimethylammonium bromide used is changed from the original 19.6g to 4.9g. The pore diameter, specific surface area, and pore volume of hollow spherical mesoporous carbon nitride are shown in Table 1.

Embodiment 3

[0023] The preparation process of this example is the same as that of Example 1, except that the amount of ethyl acetate used is changed from the original 35mL to 15mL. The pore diameter, specific surface area, and pore volume of hollow spherical mesoporous carbon nitride are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com