Preparation method of PVC profile with strong aging resistance

A kind of profile, calcium carbonate technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

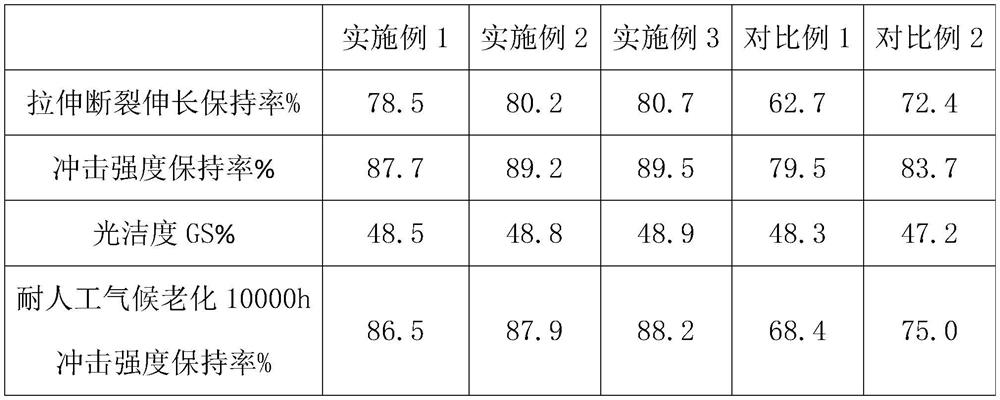

Examples

Embodiment 1

[0018] A preparation method for a strong anti-aging PVC profile, comprising the following steps:

[0019] A adopts polyvinyl chloride, calcium carbonate, stabilizer and processing aid ACR to mix in proportion to obtain base material;

[0020] B uses polyvinyl chloride, polymethyl methacrylate, aluminum silicate powder, silane coupling agent, modified calcium carbonate, stabilizer, ultraviolet absorber, antioxidant, stearic acid, glass fiber, processing aid ACR and The pigments are mixed in proportion to obtain the surface material;

[0021] C respectively heat and melt the premixed materials of the base material and the surface layer material at 185° C. to obtain the base layer molten material and the surface layer molten material respectively;

[0022] D Composite the base-layer molten material and the surface-layer molten material in a co-extrusion die, so that the surface-layer molten material is evenly pasted on the surface of the base-layer molten material to obtain a PV...

Embodiment 2

[0031] A preparation method for a strong anti-aging PVC profile, comprising the following steps:

[0032] A adopts polyvinyl chloride, calcium carbonate, stabilizer and processing aid ACR to mix in proportion to obtain base material;

[0033] B uses polyvinyl chloride, polymethyl methacrylate, aluminum silicate powder, silane coupling agent, modified calcium carbonate, stabilizer, ultraviolet absorber, antioxidant, stearic acid, glass fiber, processing aid ACR and The pigments are mixed in proportion to obtain the surface material;

[0034] C respectively heat and melt the premixed materials of the base material and the surface layer material at 195° C. to obtain the base layer molten material and the surface layer molten material respectively;

[0035] D Composite the base-layer molten material and the surface-layer molten material in a co-extrusion die, so that the surface-layer molten material is evenly pasted on the surface of the base-layer molten material to obtain a PV...

Embodiment 3

[0044] A preparation method for a strong anti-aging PVC profile, comprising the following steps:

[0045] A adopts polyvinyl chloride, calcium carbonate, stabilizer and processing aid ACR to mix in proportion to obtain base material;

[0046] B uses polyvinyl chloride, polymethyl methacrylate, aluminum silicate powder, silane coupling agent, modified calcium carbonate, stabilizer, ultraviolet absorber, antioxidant, stearic acid, glass fiber, processing aid ACR and The pigments are mixed in proportion to obtain the surface material;

[0047] C respectively heat and melt the premixed materials of the base material and the surface layer at 160° C. to obtain the base layer molten material and the surface layer molten material respectively;

[0048] D Composite the base-layer molten material and the surface-layer molten material in a co-extrusion die, so that the surface-layer molten material is evenly pasted on the surface of the base-layer molten material to obtain a PVC profile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com