Foam type low-density silicone rubber-based flexible neutron shielding material and preparation method thereof

A shielding material and low-density technology, which is applied in the field of foam-type low-density silicone rubber-based flexible neutron shielding materials and its preparation, can solve the problems of unfavorable portability and limited flexibility, and achieve good environmental friendliness, good mechanical strength and Effects of temperature resistance and excellent neutron shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

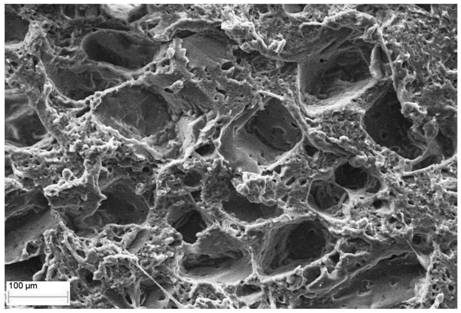

[0055] A foam-type low-density silicone rubber-based flexible neutron shielding material, its formula includes: 150g of phenyl silicone rubber compound, 78g of neutron absorber, 15g of interface fusion agent, and 300g of density regulator by weight;

[0056] The preparation method of the foam-type low-density silicone rubber-based flexible neutron shielding material comprises the following steps:

[0057] Step 1. Put 200g of phenyl silicone rubber with a phenyl content of 4.2% into a double-roll mill, add 20g of white carbon black at 50°C, and knead for 10 minutes to make a phenyl silicone rubber mix. use;

[0058] Step 2. Take a mixture of cubic boron nitride and simple boron with a mass ratio of 25:1, grind it for 15 minutes, and then bake it at 80°C for 4 hours to be used as a neutron absorber;

[0059] Step 3. Take hydroxyl silicone oil and trimethylolpropane trimethacrylate with a mass ratio of 3:2, and then place them in a vacuum drying oven at room temperature and 1KPa...

Embodiment 2

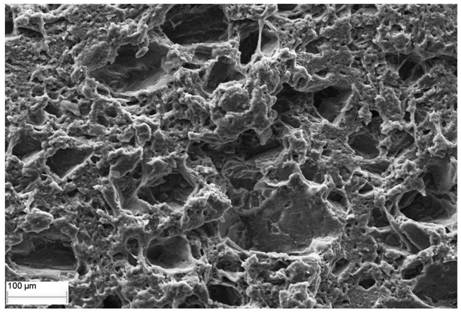

[0088] A foam-type low-density silicone rubber-based flexible neutron shielding material, its formula includes: 150g of phenyl silicone rubber compound, 183g of neutron absorber, 26g of interface fusion agent, and 250g of density regulator by weight;

[0089] The preparation method of the foam-type low-density silicone rubber-based flexible neutron shielding material comprises the following steps:

[0090] Step 1. Put 200g of phenyl silicone rubber with a phenyl content of 7% into a double-roll mill, add 20g of white carbon black at 50°C, and knead for 10 minutes to make a phenyl silicone rubber mix. use;

[0091] Step 2. Take a mixture of cubic boron nitride and simple boron with a mass ratio of 35:9, grind it for 15 minutes, and then bake it at 80° C. for 4 hours, and use it as a neutron absorber;

[0092] Step 3. Take hydroxyl silicone oil and trimethylolpropane trimethacrylate with a mass ratio of 10:3, and then place them in a vacuum drying oven at room temperature and 1...

Embodiment 3

[0098] A foam-type low-density silicone rubber-based flexible neutron shielding material, its formula includes: 100g of phenyl silicone rubber compound, 155g of neutron absorber, 20g of interface fusion agent, and 100g of density regulator by weight;

[0099] The preparation method of the foam-type low-density silicone rubber-based flexible neutron shielding material comprises the following steps:

[0100] Step 1: Take 100g of raw phenyl silicone rubber with a phenyl content of 4% and put it into a double-roll mill, add 10g of white carbon black at 40°C, and knead for 10 minutes to make phenyl silicone rubber. Glue ready for use;

[0101] Step 2: Take the hexagonal boron nitride solid, grind it for 10 minutes, and then bake it at 110°C for 2 hours as a neutron absorber for use;

[0102] Step 3. Take hydroxyl silicone oil and trimethylolpropane trimethacrylate according to the mass ratio of 4:1, and then place them in a vacuum drying oven at room temperature and 10KPa for 12 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com