Preparation method of nano-material modified anti-corrosion high-resistance electrophoresis aluminum profile

A technology of nano-materials and aluminum profiles, applied in the field of aluminum profiles, can solve problems such as low fullness, increased coating costs, and reduced corrosion resistance of aluminum profiles, so as to achieve the effect of improving anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

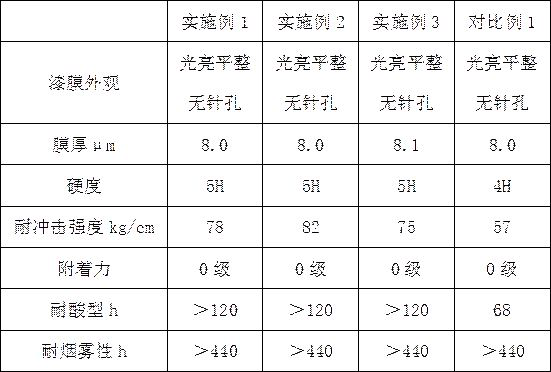

Examples

Embodiment 1

[0019] A method for preparing a nano-material modified anti-corrosion and high-resistance electrophoretic aluminum profile, comprising the following steps:

[0020] A. Degrease, wash, neutralize, and wash the aluminum profiles in sequence to obtain pretreated aluminum profiles;

[0021] B. Place the pretreated aluminum profile in a sulfuric acid oxidation tank for electrolytic oxidation treatment and wash with water;

[0022] C. Disperse tetrabutyl titanate in absolute ethanol and stir to obtain a suspension of tetrabutyl titanate in absolute ethanol, then transfer it to a reaction kettle, react at 205°C for 2.5h, and cool to room temperature, Centrifugal washing, drying, and high-temperature calcination to obtain hollow spherical titanium dioxide; then dry-grind hollow spherical titanium dioxide to control the particle size at 50-120nm; ultrasonically disperse nanoscale hollow spherical titanium dioxide in deionized water, and then add it to polyacrylic acid In the ester emu...

Embodiment 2

[0030] A method for preparing a nano-material modified anti-corrosion and high-resistance electrophoretic aluminum profile, comprising the following steps:

[0031] A. Degrease, wash, neutralize, and wash the aluminum profiles in sequence to obtain pretreated aluminum profiles;

[0032] B. Place the pretreated aluminum profile in a sulfuric acid oxidation tank for electrolytic oxidation treatment and wash with water;

[0033] C. Disperse tetrabutyl titanate in absolute ethanol and stir to obtain a suspension of tetrabutyl titanate in absolute ethanol, then transfer it to a reaction kettle, react at 220°C for 2 hours, cool to room temperature, and centrifuge Washing, drying, and high-temperature calcination to obtain hollow spherical titanium dioxide; then dry-grind hollow spherical titanium dioxide to control the particle size at 50-120nm; ultrasonically disperse nanoscale hollow spherical titanium dioxide in deionized water, and then add it to polyacrylate In the emulsion, a...

Embodiment 3

[0041] A method for preparing a nano-material modified anti-corrosion and high-resistance electrophoretic aluminum profile, comprising the following steps:

[0042] A. Degrease, wash, neutralize, and wash the aluminum profiles in sequence to obtain pretreated aluminum profiles;

[0043] B. Place the pretreated aluminum profile in a sulfuric acid oxidation tank for electrolytic oxidation treatment and wash with water;

[0044] C. Disperse tetrabutyl titanate in absolute ethanol and stir to obtain a suspension of tetrabutyl titanate in absolute ethanol, then transfer it to a reaction kettle, react at 180°C for 3 hours, cool to room temperature, and centrifuge Washing, drying, and high-temperature calcination to obtain hollow spherical titanium dioxide; then dry-grind hollow spherical titanium dioxide to control the particle size at 50-120nm; ultrasonically disperse nanoscale hollow spherical titanium dioxide in deionized water, and then add it to polyacrylate In the emulsion, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com