Waterproof moisture-permeable film and preparation method thereof

A technology of waterproof and moisture-permeable membrane and moisture-permeable membrane, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., and can solve problems such as uneven micropore structure, uneven micropore, complicated method and process, etc. , to achieve improved waterproof performance and moisture permeability, excellent moisture permeability and waterproof performance, and uniform microporous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

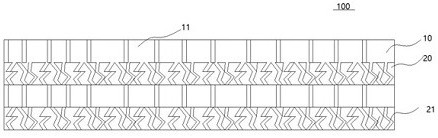

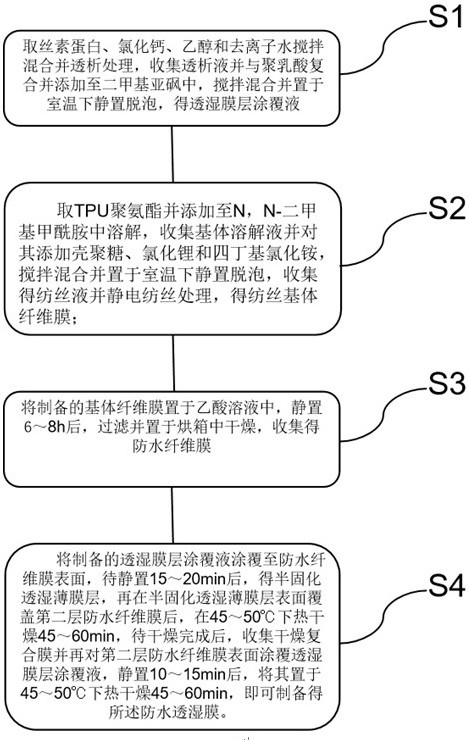

[0037] S1. Preparation of the coating solution for the moisture-permeable membrane layer 10; stir and mix silk fibroin, calcium chloride, ethanol and deionized water and dialyze, collect the dialysate and compound it with polylactic acid and add it to dimethyl sulfoxide , stirred and mixed, and placed at room temperature for defoaming to obtain the coating solution for the moisture-permeable film layer 10;

[0038] S2, preparation of matrix fiber membrane; take TPU polyurethane and add to N,N-dimethylformamide to dissolve, collect matrix solution and add chitosan, lithium chloride and tetrabutylammonium chloride to it, stir Mixing and standing at room temperature for defoaming, collecting the spinning solution and performing electrospinning treatment to obtain a spinning matrix fiber film;

[0039] S3. Preparation of waterproof fiber membrane, the prepared base fiber membrane is placed in acetic acid solution, after standing for 6-8 hours, filtered and dried in an oven, and the ...

Embodiment 1

[0051] In parts by weight, weigh 10 parts of silk fibroin, 3 parts of calcium chloride, 6 parts of ethanol and 60 parts of deionized water, mix and dialyze, collect the dialysate and compound with polylactic acid and add to dimethyl In sulfoxide, stir and mix and place it at room temperature for defoaming to obtain the coating solution for the moisture-permeable film layer 10; take TPU polyurethane and add it to N,N-dimethylformamide to dissolve, collect the matrix solution and add In parts by weight, weigh 45 parts of matrix solution, 3 parts of chitosan, 0.01 part of lithium chloride and 0.5 part of tetrabutylammonium chloride, stir and mix and place it at room temperature for defoaming, and collect Spinning solution and electrospinning treatment, control the spinning voltage to 12kV, the spinning solution flow rate to 2mL / h, the receiving distance to 9cm, electrospinning and collecting the spun fibers to obtain the spinning matrix fiber film; the prepared matrix The fiber m...

Embodiment 2

[0053] In parts by weight, weigh 12 parts of silk fibroin, 4 parts of calcium chloride, 7 parts of ethanol and 70 parts of deionized water, stir and mix and dialyze, collect the dialysate and compound with polylactic acid and add to dimethyl In sulfoxide, stir and mix and place it at room temperature for defoaming to obtain the coating solution for the moisture-permeable film layer 10; take TPU polyurethane and add it to N,N-dimethylformamide to dissolve, collect the matrix solution and add In parts by weight, weigh 47 parts of matrix solution, 4 parts of chitosan, 0.01 part of lithium chloride and 0.7 part of tetrabutylammonium chloride, stir and mix and place it at room temperature for defoaming, and collect Spinning solution and electrospinning treatment, control spinning voltage to 13kV, spinning solution flow rate to 2mL / h, receiving distance to 10cm, electrospinning and collecting spun fibers to obtain spinning matrix fiber film; the prepared matrix The fiber membrane is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com