A kind of method for preparing aldehyde compounds by two-phase hydroformylation of olefins

A technology of aldehyde compounds and hydroformyl, which is applied in the field of aldehyde synthesis, can solve the problems of poor catalyst recycling rate, harsh reaction conditions, and low conversion rate, and achieve high conversion rate, improved reaction activity, and high selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

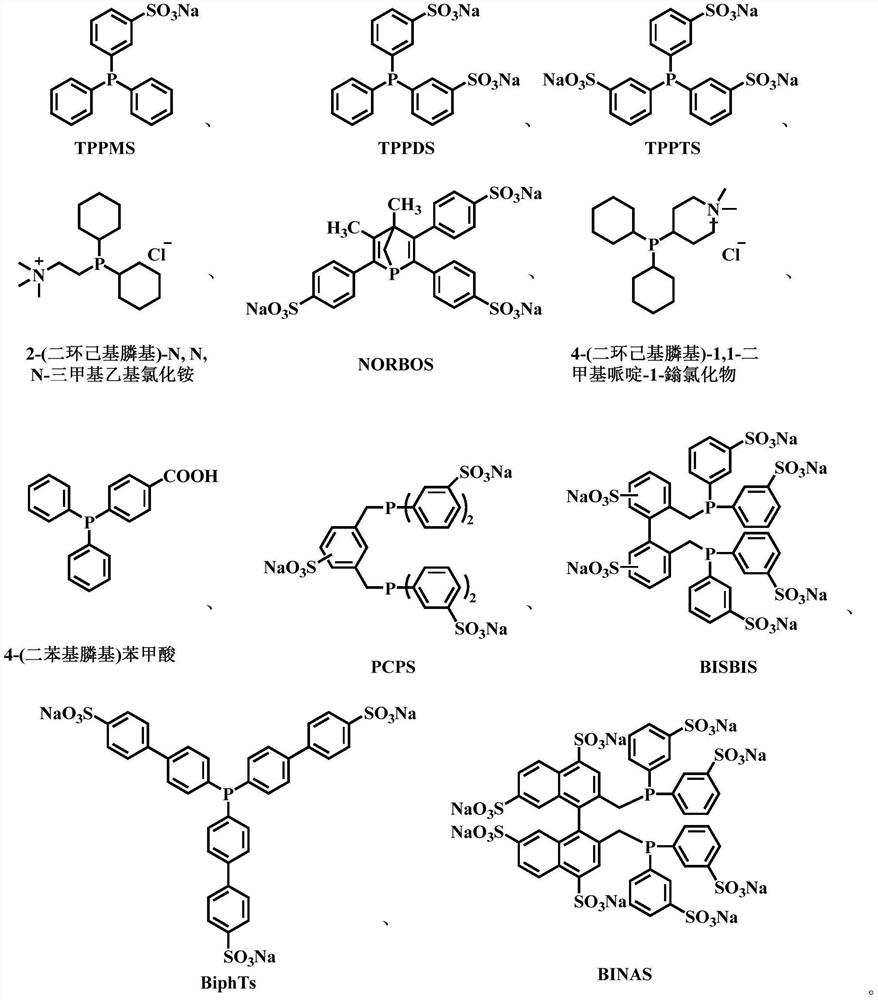

Image

Examples

Embodiment 1

[0026] This embodiment 1 provides a method for preparing aldehydes by two-phase hydroformylation of olefins, the specific process is: 0.03 grams of rhodium catalyst HRh (CO) (TPPTS) 3 , 0.05 g of TPPTS, 6 mL of formamide and 2.5 mL of 1-octene were added to a stainless steel autoclave with a magnetic stirrer and a temperature controller, and then the synthesis gas was introduced into the autoclave to replace the air in the autoclave, and repeated for 3 Once, then fill the synthesis gas with the pressure ratio of hydrogen and carbon monoxide at 1:1 to 1MPa, raise the temperature to 70°C, then react at constant temperature and pressure at a stirring speed of 1000rpm for 2 hours, cool to room temperature, release the pressure, and separate the mixture immediately after taking it out. It consists of upper and lower layers, and the composition of the upper layer is analyzed by gas chromatography. It is calculated that the conversion rate of 1-octene is 97.3%, the selectivity of nona...

Embodiment 2

[0028] This embodiment 2 provides a method for preparing aldehyde compounds by two-phase hydroformylation of olefins, the specific process is: 0.03 gram of rhodium catalyst HRh (CO) (TPPTS) 3 , 0.05 grams of TPPTS, 6 mL of water and 2.5 mL of 1-octene were added to a stainless steel autoclave with a magnetic stirrer and a temperature controller, and then the air in the autoclave was replaced by synthesis gas, repeated 3 times , then filled with synthesis gas with a pressure ratio of hydrogen and carbon monoxide of 1:1 to 1MPa, heated to 70°C, then reacted at a constant temperature and pressure at a stirring speed of 1000rpm for 2 hours, cooled to room temperature, and released the pressure. After the mixture was taken out, it was divided into There are two upper and lower layers, and the composition of the upper layer is analyzed by gas chromatography. After calculation, the conversion rate of 1-octene is 20.4%, the selectivity of nonanal is 50.7%, and the selectivity of linear...

Embodiment 3

[0030] This embodiment 3 provides a method for preparing aldehydes by two-phase hydroformylation of olefins, the specific process is: 0.03 grams of rhodium catalyst RhCl (CO) (TPPTS) 2 , 0.13 g of TPPTS, 12 mL of formamide and 3.6 mL of 1-octene were added to a stainless steel autoclave with a magnetic stirrer and a temperature controller, and then the synthesis gas was introduced into the autoclave to replace the air in the autoclave, and repeated for 3 Once, then fill the synthesis gas with hydrogen and carbon monoxide pressure ratio of 1:1 to 2MPa, raise the temperature to 60°C, then react at a constant temperature and pressure with a stirring speed of 1000rpm for 2.5 hours, cool to room temperature, release the pressure, and separate the mixture immediately after taking it out. It consists of upper and lower layers, and the composition of the upper layer is analyzed by gas chromatography. It is calculated that the conversion rate of 1-octene is 95.8%, the selectivity of non...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com