Preparation method of high-fluidity modified polytrifluorochloroethylene resin

A polychlorotrifluoroethylene and chlorotrifluoroethylene technology, which is applied in the field of preparation of high-fluidity modified polychlorotrifluoroethylene resin, can solve the problem of inhomogeneity, unstable product performance, and inability to uniformity of polymer state. Guarantee, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

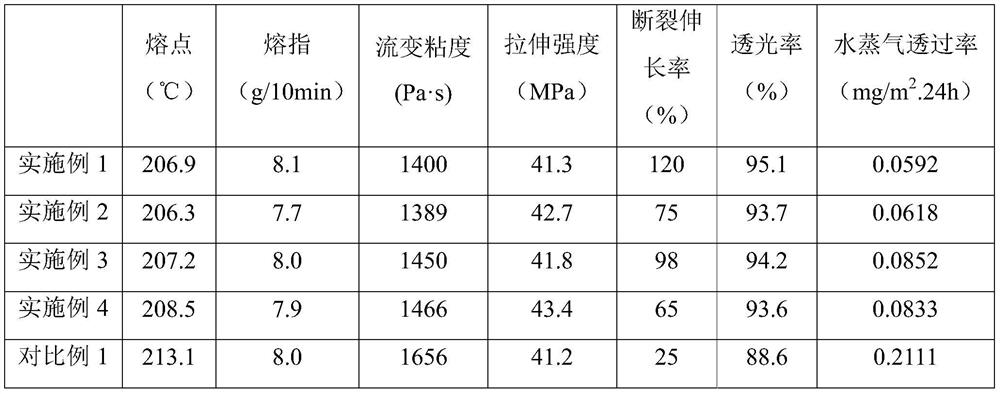

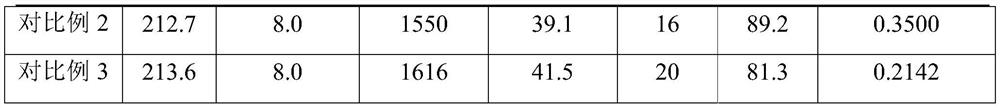

Embodiment 1

[0029] Taking a 10L high-pressure reactor as an example, add 5L of deionized water, 25g of potassium dihydrogen phosphate, vacuumize, replace oxygen with nitrogen, start stirring at a stirring speed of 400rpm, add 2kg of chlorotrifluoroethylene monomer and 22g of perfluoropropylethylene base ether, then dissolve 22g of azobisisobutylamidine hydrochloride with deionized water and mix evenly, then add it to the reaction kettle, raise the temperature to 55°C, control the reaction temperature at 55°C±1°C, and stop the reaction after stirring for 10 hours , release the pressure to obtain powdered polytrifluoroethylene resin, wash and dry the obtained resin.

[0030] Add 0.1 wt% of fluorochloro oil with a molecular weight of 9000 and 0.1 wt% of boron nitride with a particle size of 0.3 μm to the resin obtained above, mix uniformly in a high-speed mixer, granulate through a screw extruder, and extrude The extruder barrel temperature is 260°C-310°C, the screw speed is 100rpm, the mate...

Embodiment 2

[0032] Take a 10L high-pressure reactor as an example, add 5L deionized water, 25g potassium dihydrogen phosphate, vacuumize, replace oxygen with nitrogen, start stirring at a stirring speed of 500rpm, add 2kg of chlorotrifluoroethylene monomer and 28g of perfluoromethylethylene base ether, then dissolve 28g of azobisisobutylamidine hydrochloride with deionized water and mix evenly, then add it to the reaction kettle, raise the temperature to 40°C, control the reaction temperature at 40°C±1°C, and stop the reaction after stirring for 11 hours , release the pressure to obtain powdered polytrifluoroethylene resin, wash and dry the obtained resin.

[0033] Add 0.1wt% of perfluoropolyether with a molecular weight of 9800 and 0.35wt% of talcum powder with a particle size of 0.5 μm to the resin obtained above, mix uniformly in a high-speed mixer, granulate through a screw extruder, and extrude The temperature of the extruder barrel is 260°C-310°C, and the screw speed is 100rpm. The ...

Embodiment 3

[0035] Take a 10L high-pressure reactor as an example, add 5L deionized water, 20g sodium dihydrogen phosphate, vacuumize, replace oxygen with nitrogen, start stirring at a stirring speed of 500rpm, add 2kg of chlorotrifluoroethylene monomer and 15g of perfluoroethylethylene base ether, then dissolve 16g of azobisisobutylamidine hydrochloride with deionized water and mix evenly, then add it to the reaction kettle, raise the temperature to 62°C, control the reaction temperature at 62°C±1°C, and stop the reaction after stirring for 9 hours , release the pressure to obtain powdered polytrifluoroethylene resin, wash and dry the obtained resin.

[0036]Add 0.5wt% of fluorochloro oil with a molecular weight of 8200 and 0.5wt% of boron nitride with a particle size of 0.3 μm to the resin obtained above, mix uniformly in a high-speed mixer, granulate through a screw extruder, and extrude The extruder barrel temperature is 260°C-310°C, the screw speed is 100rpm, the material is melted b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com