Preparation method of tetraethoxysilane-coated perovskite nanocrystals

A technology of ethyl orthosilicate and perovskite, which is applied in the fields of nanotechnology, nanotechnology, nano-optics for materials and surface science, and can solve the problems of unstable nanocrystals, easy decomposition and deterioration, and limited wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: CsPbBr 3 Preparation of NCs

[0034] (1-1) Preparation of the precursor: a 100ml three-necked flask was filled with CsCO 3 0.5g, ODE (1-octadecene) 15ml, OA (oleic acid) 3ml, raise the temperature to 120°C and keep it for 60min, then raise the temperature to 150°C for use; the whole process is under N 2 Under the atmosphere.

[0035] (1-2) Preparation of perovskite nanocrystals:

[0036] PbBr was charged into another three-necked flask 2 0.3mmol and ODE (1-octadecene) 15ml, raise the temperature to 120°C and keep it for 60min, then add 0.5ml OA (oleic acid) and 0.5ml OAm (oleylamine), and raise the temperature to 150°C ℃, after the solid is completely dissolved, quickly inject 0.5ml of the precursor solution into the mixed solution, react for 10s and put it in ice water to cool to room temperature; the whole process is under N 2 Under the atmosphere.

[0037] (1-3) Purification treatment of perovskite nanocrystals:

[0038] Centrifuge the cooled perovski...

Embodiment 2-6

[0039] Example 2-6: Preparation of perovskite nanocrystals coated with orthosilicate

[0040] Get the perovskite CsPbX that embodiment 1 prepares 3 Nanocrystalline dispersion 2, add different volumes of ethyl orthosilicate to it respectively, so that the volume of orthosilicate accounts for the volume of perovskite CsPbX 3 25% (embodiment 2), 33% (embodiment 3), 50% (embodiment 4), 67% (embodiment 5), 75% (embodiment 6) of the dispersion liquid volume of nanocrystal, stir 3min to make After mixing evenly, dry in an oven at 60°C for 10 hours to obtain perovskite nanocrystals QDs@0.25TEOS (Example 2), QDs@0.33TEOS (Example 3), and QDs@0.5TEOS coated with orthosilicate (Example 4), QDs@0.67TEOS (Example 5), QDs@0.75TEOS (Example 6).

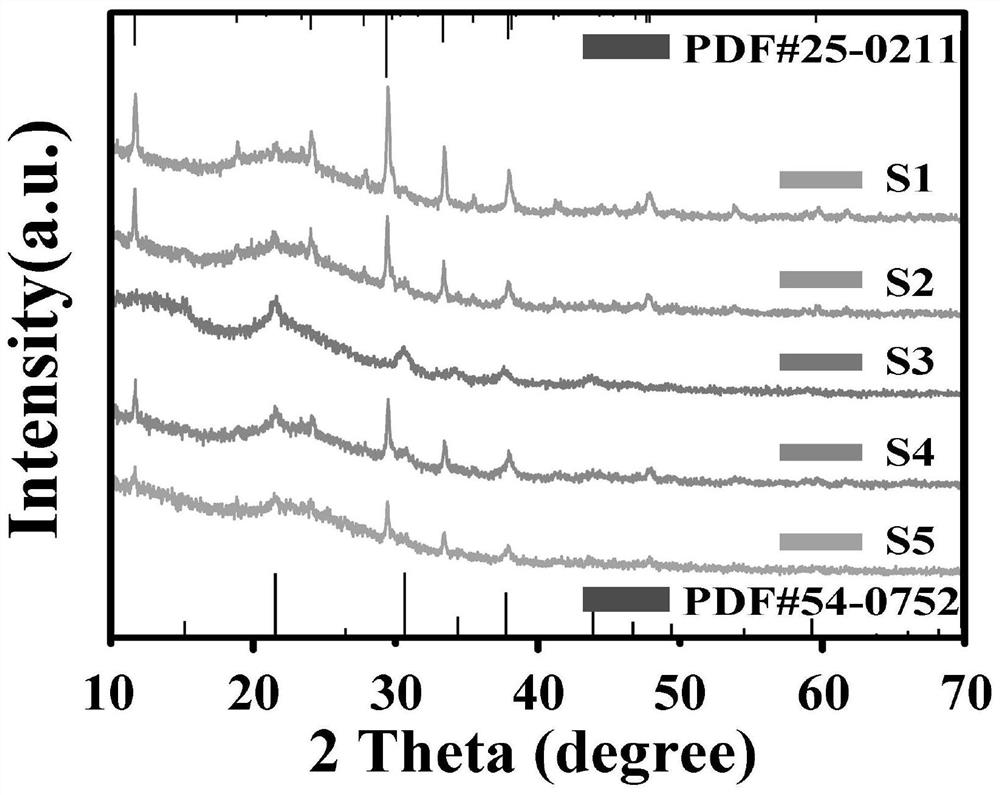

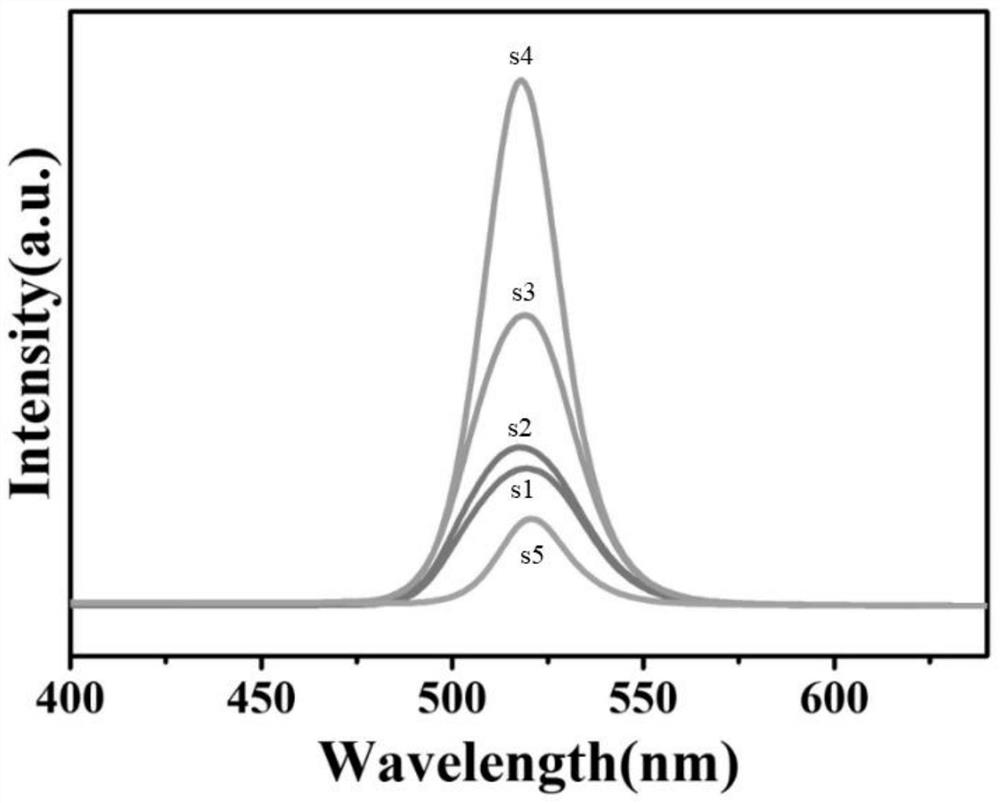

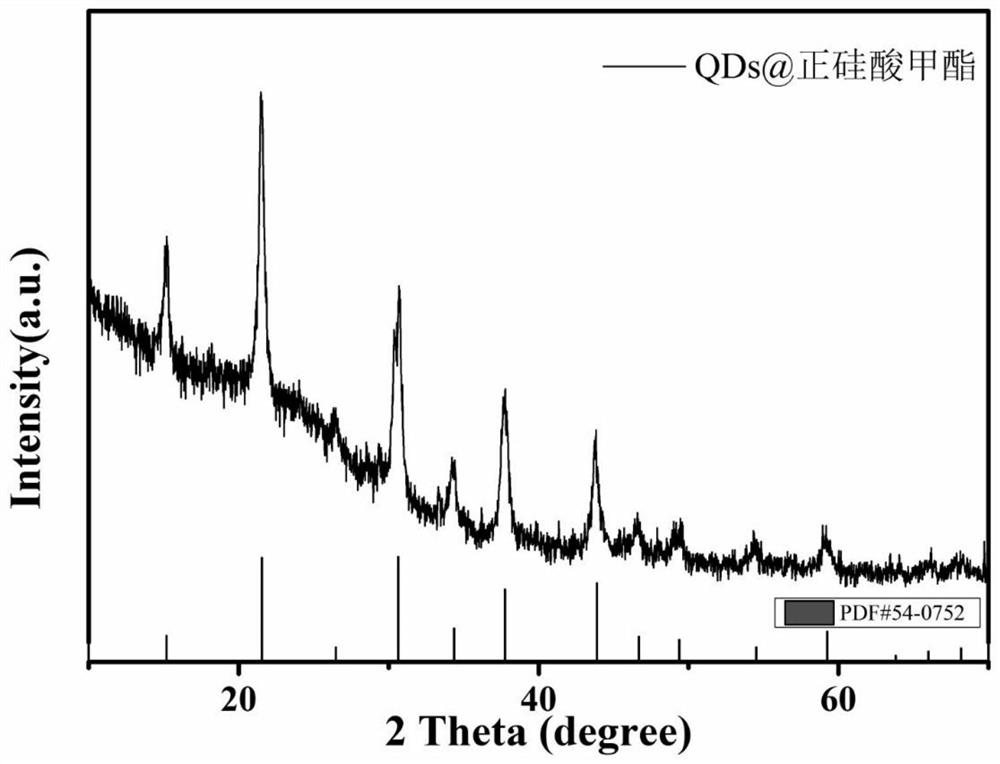

[0041] figure 1 It is the X-ray diffraction (XRD) pattern of a series of perovskite nanocrystals coated with tetraethyl orthosilicate prepared in Example 2-6, wherein S1 is QDs@0.25TEOS, S2 is QDs@0.33TEOS, and S3 is QDs@0.5TEOS, S4 is QDs@0.67T...

Embodiment 11

[0053] Embodiment 11: Stability experiment

[0054] The perovskite CsPbBr that 2mL embodiment 1 prepares 3 The nanocrystal dispersion 2 was transferred to a cuvette, and the fluorescence intensity at this time was measured. Then place the cuvette in an ultrasonic cleaning machine for 30 minutes to measure the fluorescence intensity after ultrasonication. For comparison of fluorescence intensity, see Figure 7-a .

[0055] With the CsPb that embodiment 4 obtains 2 x 5 Transfer 0.2 g of sample powder @50% TEOS to a cuvette, add 2 ml of ultrapure water, and measure the fluorescence intensity at this time. Then place the cuvette in an ultrasonic cleaning machine for 30 minutes to measure the fluorescence intensity after ultrasonication. For comparison of fluorescence intensity, see Figure 7-b .

[0056] With the CsPb that embodiment 5 obtains 2 x 5 Transfer 0.2 g of sample powder @67% TEOS to a cuvette, add 2 ml of ultrapure water, and measure the fluorescence intensity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com