Photothermal conversion textile based on self-assembled molybdenum disulfide nanospheres and preparation method of photothermal conversion textile

A light-to-heat conversion and molybdenum disulfide technology, which is applied in the fields of molybdenum sulfide, textiles and papermaking, nanotechnology, etc., can solve the problems of complicated process and unfavorable wide application of loaded products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Accurately weigh 0.3 g of anhydrous sodium molybdate; accurately weigh 0.8 g of L-cysteine; add the two into 100ml of deionized water, fully dissolve, continue to stir for 24 hours, and centrifuge to obtain the precursor substance; Disperse it in 60ml of deionized water, transfer it to a polytetrafluoroethylene hydrothermal kettle, react at 180°C for 20 h, and obtain a black precipitate; centrifuge the precipitate, wash it with water and alcohol several times, and dry it in vacuum. Molybdenum disulfide hollow nanospheres were obtained.

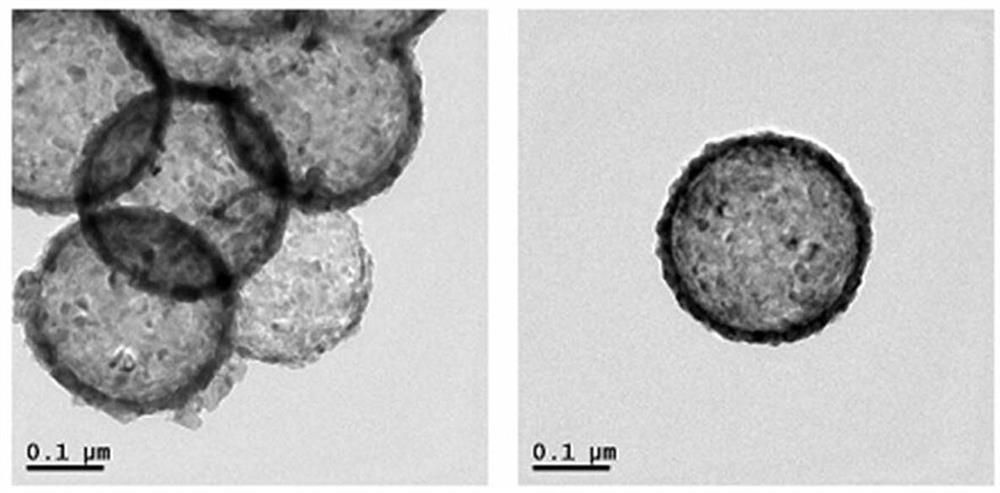

[0024] See attached figure 1 The transmission electron microscope image of the molybdenum disulfide hollow nanospheres prepared in Example 1 shows that the radial size of the molybdenum disulfide hollow nanospheres is about 270 nm, with uniform size and good dispersion.

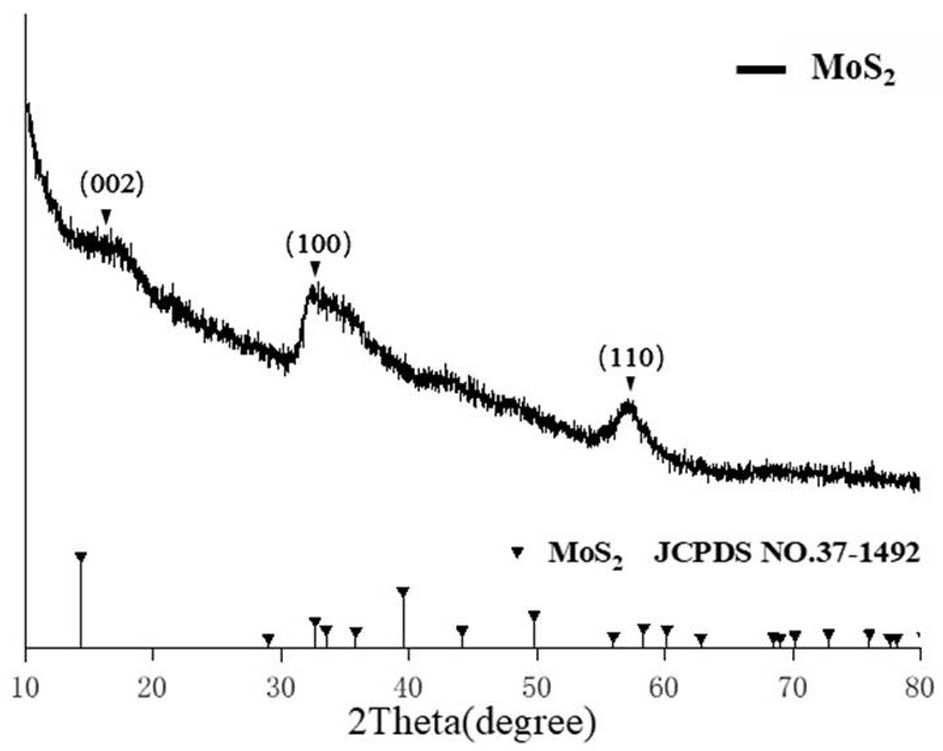

[0025] See attached figure 2 , is the X-ray diffraction pattern of molybdenum disulfide hollow nanospheres prepared in this example, and the results show that the p...

Embodiment 2

[0031] Accurately weigh 0.3 g of anhydrous sodium molybdate; accurately weigh 0.8 g of dimethyl sulfoxide; add the two into 100ml of deionized water, fully dissolve, continue to stir for 24 hours, and centrifuge to obtain the precursor substance; Disperse it in 60ml of deionized water, transfer it to a polytetrafluoroethylene hydrothermal kettle, react at 180°C for 18h, and obtain a black precipitate; centrifuge the precipitate, wash it with water and alcohol several times, and dry it in vacuum to obtain Molybdenum disulfide hollow nanospheres.

[0032] The prepared molybdenum disulfide was dispersed into a nano slurry, and the cotton textile was treated according to the dosage of 1.5%, to obtain a self-heating cotton textile fabric.

Embodiment 3

[0034] Accurately weigh 0.3 g of anhydrous ammonium heptahydrate ammonium molybdate; accurately weigh 0.8 g of thiourea; add the two into 100ml deionized water, fully dissolve, then continue to stir for 24 hours, and centrifuge to obtain the precursor substance; Disperse it in 60ml of deionized water, transfer it to a polytetrafluoroethylene hydrothermal kettle, react at 180°C for 22 h, and obtain a black precipitate; centrifuge the precipitate, wash it with water and alcohol several times, and dry it in vacuum to obtain Molybdenum disulfide hollow nanospheres.

[0035] The prepared molybdenum disulfide was dispersed into nano pulp, and the cotton textile was treated according to the dosage of 3%, to obtain the self-heating cotton textile fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com