Electrode material, preparation method and application thereof, and sodium-air battery

An electrode material, air battery technology, applied in nanotechnology for materials and surface science, electrical components, battery electrodes, etc. Issues such as reduced efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Some embodiments of the present invention also provide a preparation method of the above-mentioned electrode material, which includes:

[0043] S1. Preparation of a compound whose unit cell structure is a Prussian blue structure.

[0044] The specific preparation process is: reacting metal salt and ferrocyanate. During the reaction, a reaction occurs between ferrocyanate ions and metal ions to generate precipitates.

[0045] In some embodiments, in order to allow the metal salt and ferrocyanate to react, generally, the metal salt and ferrocyanate react in a solution system.

[0046] Specifically, the metal salt is first dissolved in a solvent, and then ferrocyanate is added for reaction to obtain a precipitate. Wherein, the solvent is generally water.

[0047]Wherein, the metal salt can be nickel salt, cobalt salt or iron salt; in some embodiments, the metal salt is nickel, cobalt, iron nitrate, sulfate or chloride. For example, the above metal salts may be nickel n...

Embodiment 1

[0061] This embodiment provides a method for preparing an electrode material, which specifically includes:

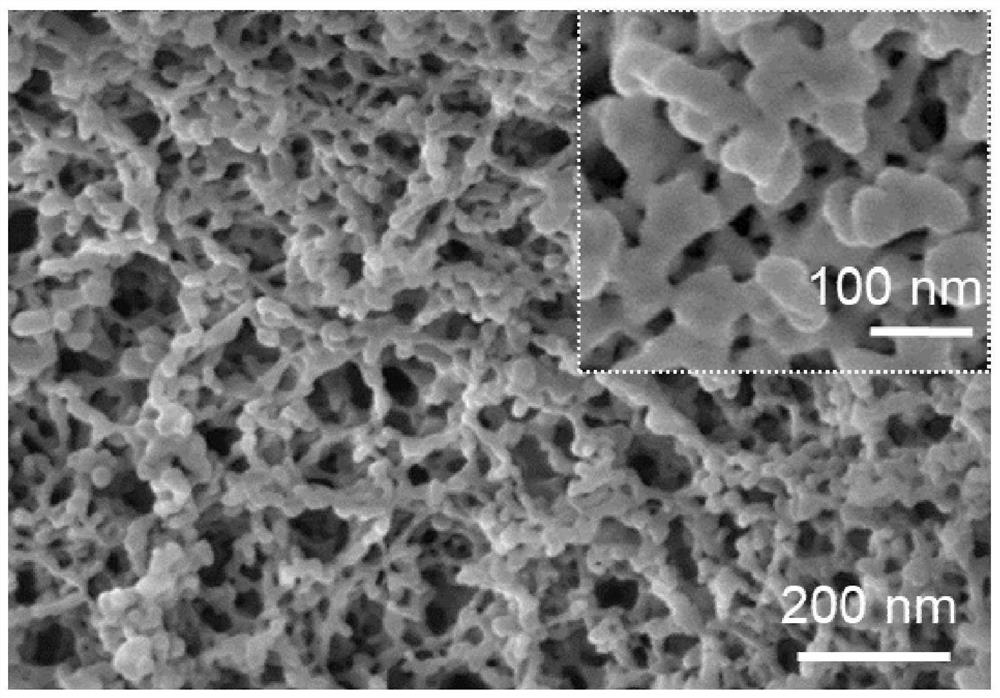

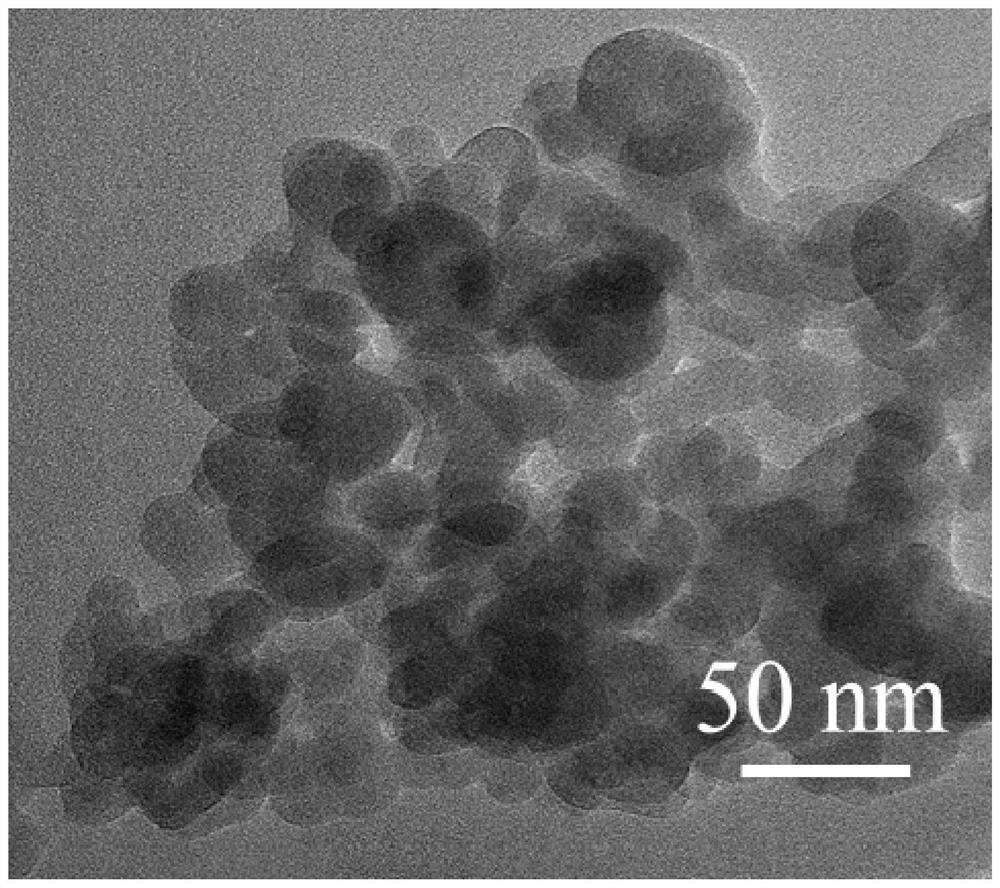

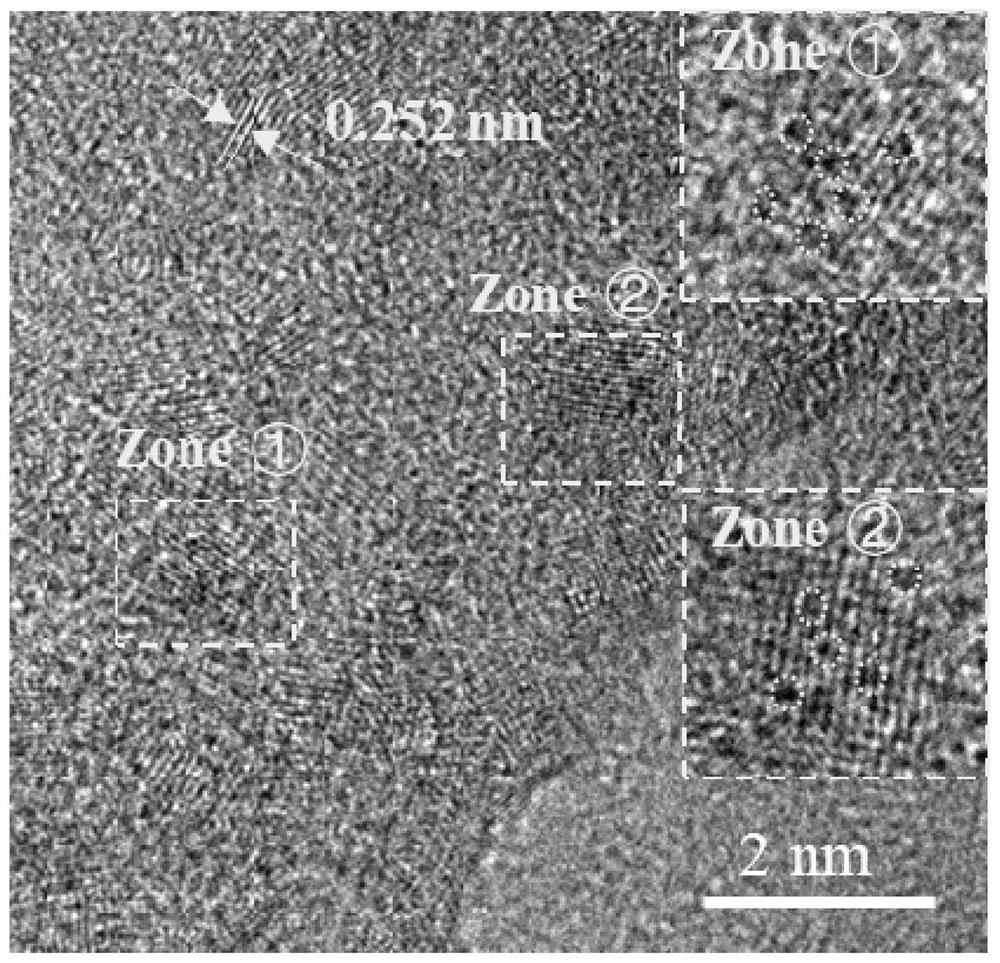

[0062] The Co-PBA Prussian blue structure was synthesized from cobalt nitrate and sodium ferrocyanide. Specifically, 6 mmol of cobalt nitrate was dissolved in 50 ml of deionized water to obtain solution A, 4 mmol of sodium ferrocyanide was dissolved in another 50 ml of deionized water, and stirred evenly to obtain solution B. Solution A was added dropwise to solution B and stirred for 30 min. The obtained solid was washed and centrifuged and dried to obtain a defect-free Co-PBA Prussian blue structure, which was named Co-PBA. Disperse the obtained solid material in 50ml of deionized water, add 5ml of hydrogen peroxide solution, stir for 0.3h, stir and centrifuge to obtain defect-rich nanoparticles, named D-Co-PBA.

Embodiment 2

[0064] This embodiment provides a sodium-air battery, which uses biphenyl sodium as a liquid anode, NASICON as a solid electrolyte, 0.1mol / L NaOH as an aqueous electrolyte, and D-Co-PBA+Pt / C as a catalyst, assembled to obtain The sodium-air battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com