Preparation method and application of metal organic framework MOF-808 film-based functional sandwich material

A MOF-808, metal organic framework technology, applied in electrical components, electrode carriers/current collectors, battery electrodes, etc., can solve the problem of destroying active metal sites and porous structures, reducing polysulfide binding capacity, MOFs material adsorption or Catalytic sites are limited and other problems, to achieve stable cycle performance, inhibit the shuttle effect, and improve the cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

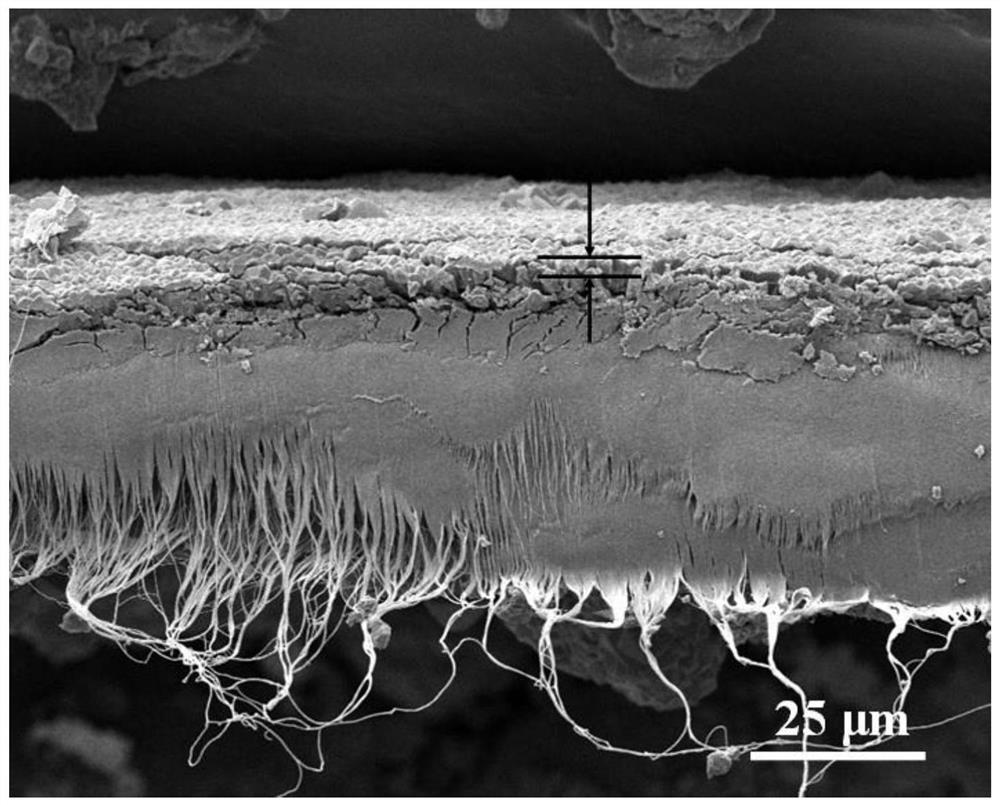

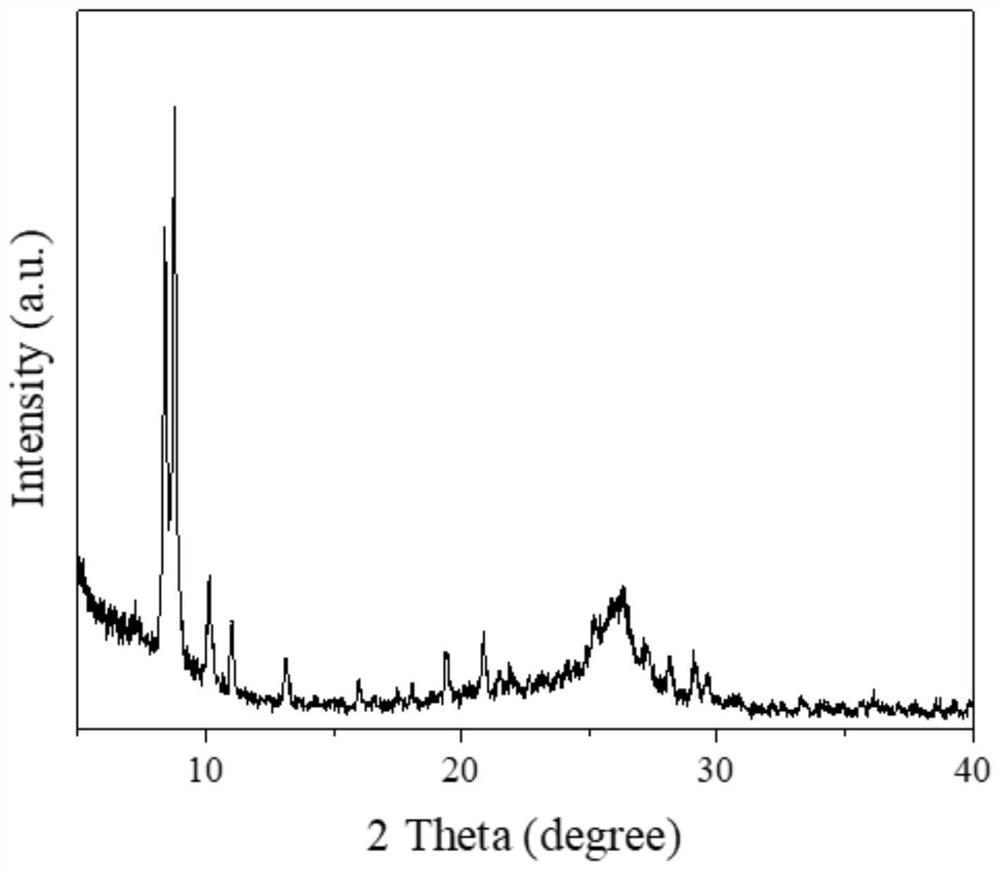

[0028] Synthesis of MOF-808 film material on carbon nanotube (CNT) film and its application in lithium-sulfur batteries:

[0029] Dissolve 1.45g of zirconium oxychloride octahydrate (4.5mmol) and 0.42g of trimesic acid (2mmol) in 20mL (1111mmol) of deionized water, stir magnetically at room temperature for 1h, then add 10mL of trifluoroacetic acid (134mmol), and ultrasonically 1h to obtain a synthetic solution. The synthesis solution was transferred to a polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle, and the carbon nanotube thin film discs cut to a diameter of 19 mm by a cutting machine were vertically immersed in the synthesis solution. The hydrothermal reactor was placed in an oven, heated at 120 °C for 3 h, and then cooled to room temperature naturally. After taking out the material, wash it several times with deionized water and absolute ethanol, and dry it at 60°C. In order to avoid the excessive increase of impedance caused by the insulatin...

Embodiment 2

[0036] The synthesis steps are the same as in Example 1, except that 1.93g of zirconium oxychloride octahydrate (6mmol) and 0.42g of trimesic acid (2mmol) are dissolved in 21.6mL (1200mmol) of deionized water during the synthesis process, and magnetically After stirring for 30 min, 10.4 mL of trifluoroacetic acid (140 mmol) was added, and the synthesis temperature was changed from 120° C. to 110° C. The other steps were the same as in Example 1.

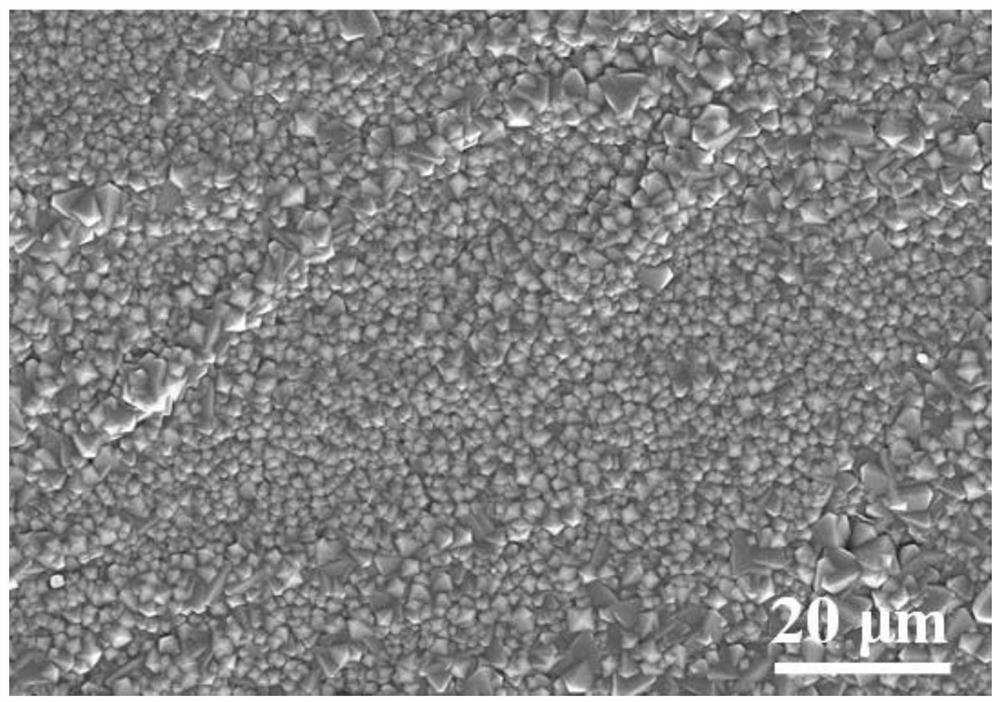

[0037] Figure 5 This is the surface SEM image of the MOF-808 film obtained in this example. It can be seen that the film layer is still dense and continuous. When it is used as a lithium-sulfur battery interlayer, the initial discharge capacity is 1185mAh g -1 , the discharge capacity after 100 cycles is 834mAh g -1 , The capacity retention rate was 70.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com