Method for preparing biodegradable transparent film by using waste wood biomass

A woody biomass and transparent film technology, applied in the field of biodegradable transparent films, can solve problems such as shortage of environment, difficult degradation, pollution, etc., and achieve the effects of low cost, solving environmental pollution, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

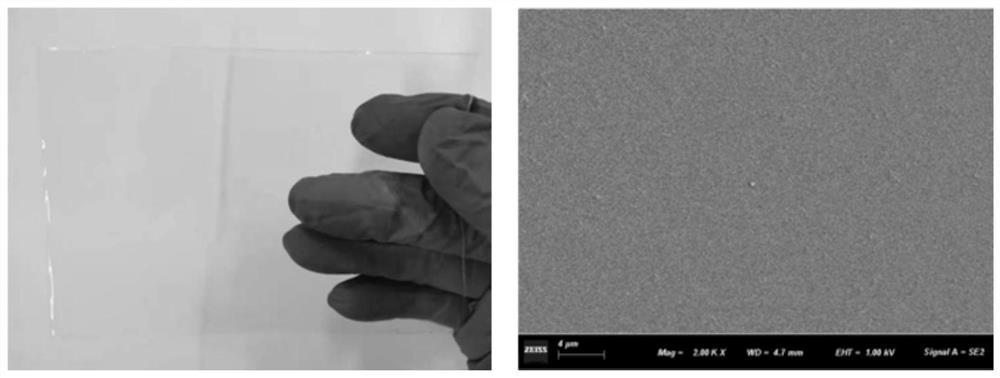

Embodiment 1

[0039] Wash and dry the discarded corn stalks with distilled water, and crush them into powder; weigh 20g of corn stalk powder and add it to a Soxhlet extractor, extract with absolute ethanol for 6 hours to dewax the powder, and then dry it in an oven at 60°C Add the above-mentioned dried corn stalk powder into the reactor, mix it with 8% methanesulfonic acid aqueous solution with 600mL mass fraction, carry out pre-hydrolysis for 4 hours under the heating condition of 80°C, filter, wash, dry and add to In another reaction vessel, add 240mL mass fraction and be 2.0% Na 2 SO 3Add 10mL of 20% NaOH solution to the aqueous solution, stir and heat in an oil bath at 100°C for 1 hour, filter the mixture after the reaction, wash the filter residue with water until it is neutral, and then dry it to obtain cellulose. Grind the above-mentioned dried cellulose into powder, weigh 5g and pour it into another reactor, add 35mL of glacial acetic acid, put it in an oil bath at 50°C for 3 hours...

Embodiment 2

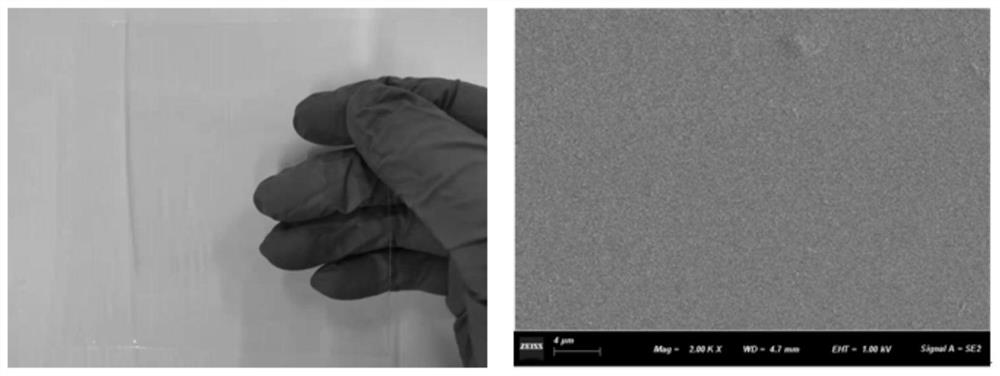

[0041] Wash and dry the discarded rice straw with distilled water, and crush it into powder; weigh 30g of rice straw powder and put it into a Soxhlet extractor, extract with absolute ethanol for 6 hours to dewax the powder, and then dry it in an oven at 60°C; Add the above dried rice straw powder into the reactor, mix it with 450mL of 4% methanesulfonic acid aqueous solution, pre-hydrolyze it at 120°C for 2 hours, filter it, wash it, dry it and add it to another reaction In the container, add 290mL of Na with a mass fraction of 1.0% 2 SO 3 Add 10 mL of NaOH solution with a mass fraction of 20% to the aqueous solution, stir and heat in an oil bath at 120°C for 1 hour, filter the mixture after the reaction, wash the filter residue with water until it is neutral, and then dry it to obtain cellulose. Grind the above dried cellulose into powder, weigh 10g and pour it into another reactor, add 100mL of glacial acetic acid, put it in an oil bath at 60°C for 2 hours, then add 50mL of...

Embodiment 3

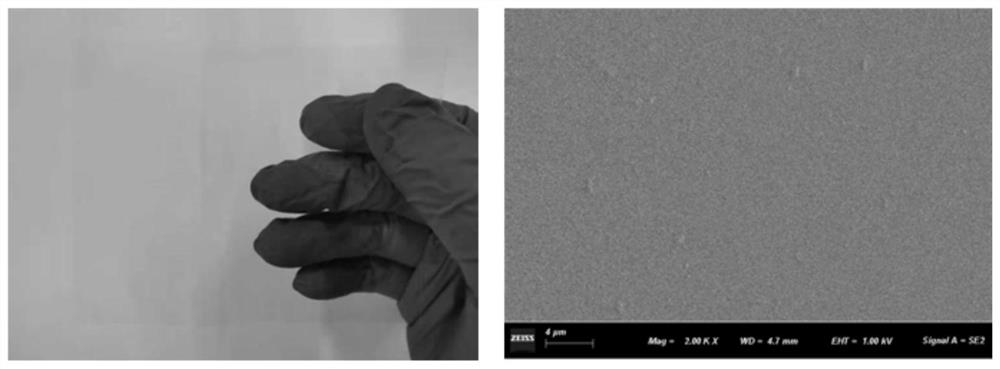

[0043] Wash and dry the discarded bamboo with distilled water, and crush it into powder; weigh 30g of bamboo powder and add it to a Soxhlet extractor, extract with absolute ethanol for 6 hours to dewax the powder, and then dry it in an oven at 60°C; The above dried bamboo powder was added to the reactor, mixed with 500mL of 4% methanesulfonic acid aqueous solution, heated at 100°C for 3 hours, then filtered, washed, dried and then added to another reaction In the container, add 290mL of Na with a mass fraction of 1.5% 2 SO 3 Add 10mL of 20% NaOH solution to the aqueous solution, stir and heat in an oil bath at 100°C for 1 hour, filter the mixture after the reaction, wash the filter residue with water until it is neutral, and then dry it to obtain cellulose. Grind the above dried cellulose into powder, weigh 10g and pour it into another reactor, add 120mL of glacial acetic acid, put it in an oil bath at 50°C for 3 hours, then add 40mL of acetic anhydride and 0.2g of sulfuric a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com