Preparation methods of high-specific-surface-area nano W powder and high-specific-surface-area nano WC powder

A high specific surface, nano technology, applied in the field of WC powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

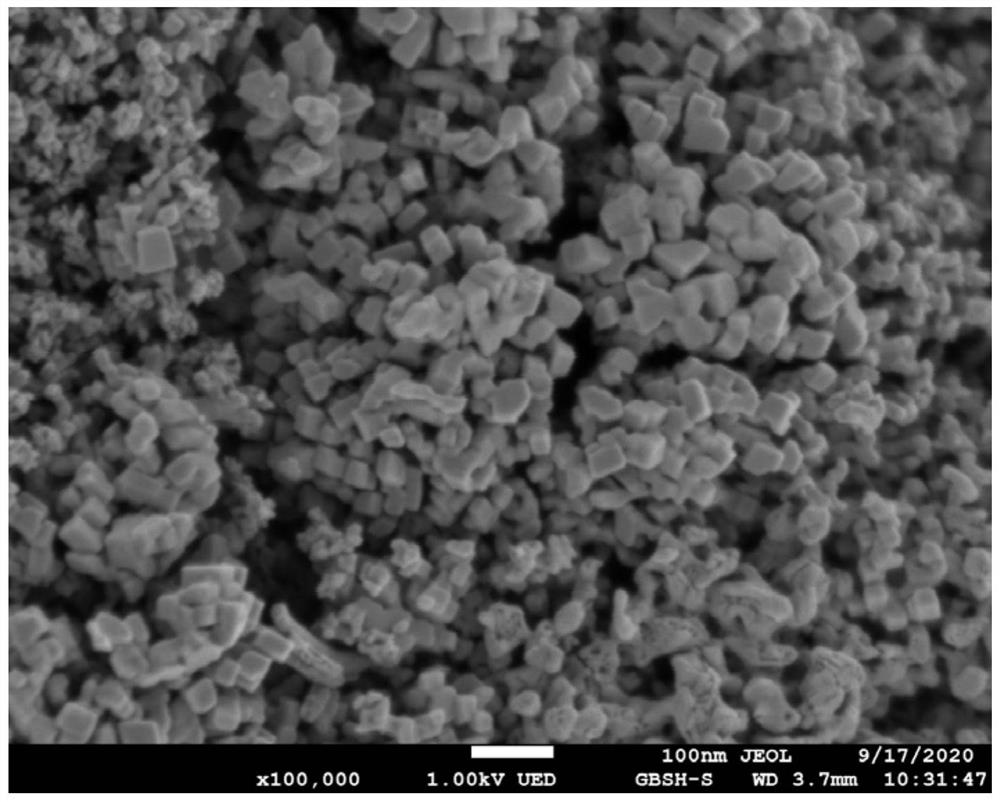

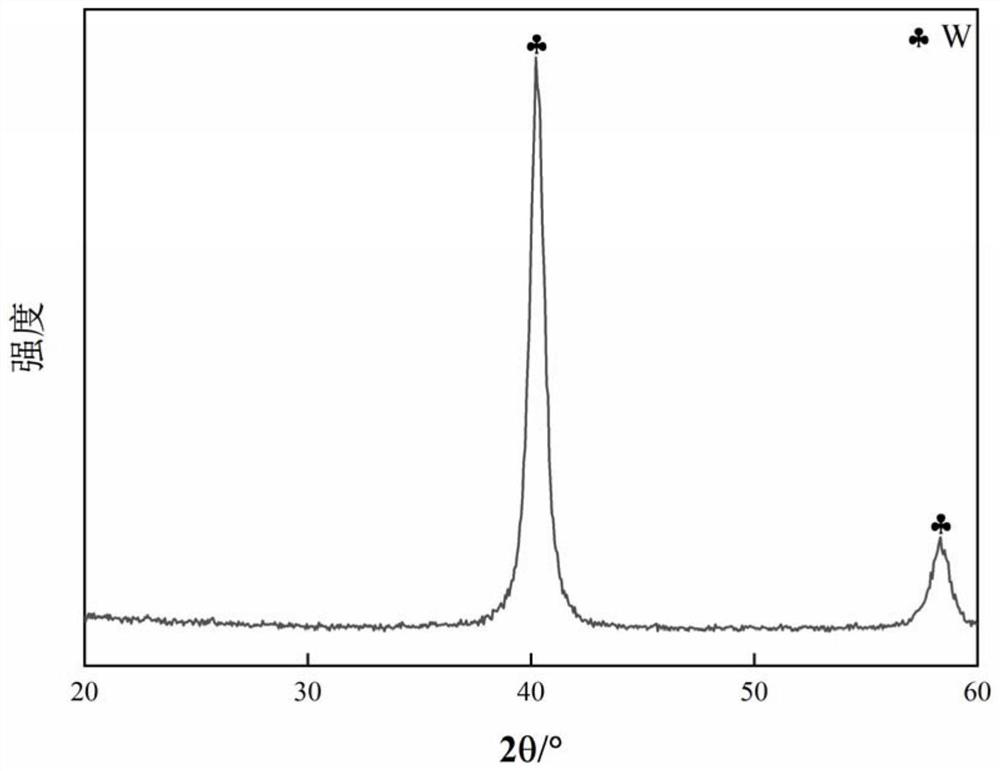

Embodiment 1

[0032] In this example, blue tungsten powder is used as raw material to prepare nano-W powder, and the process steps are as follows:

[0033] (1) Spread the blue tungsten powder on the boat, adjust the loading amount to 150g / boat, and control the thickness of the blue tungsten powder layer to 3mm;

[0034] (2) The heating zones of the five-zone hydrogen reduction furnace are divided into low-temperature zones, medium-temperature zones and high-temperature zones, wherein the first, second and third heating zones are low-temperature zones, and the length is 60% of the total length of the heating zones. The fourth heating zone is a medium temperature zone, and the length is 20% of the total length of the heating zone. The fifth heating zone is a high temperature zone, and the length is 20% of the total length of the heating zone. At 850°C, the temperature of the high temperature zone is set at 950°C;

[0035] (3) Using inverse hydrogen reduction, the determination of the hydroge...

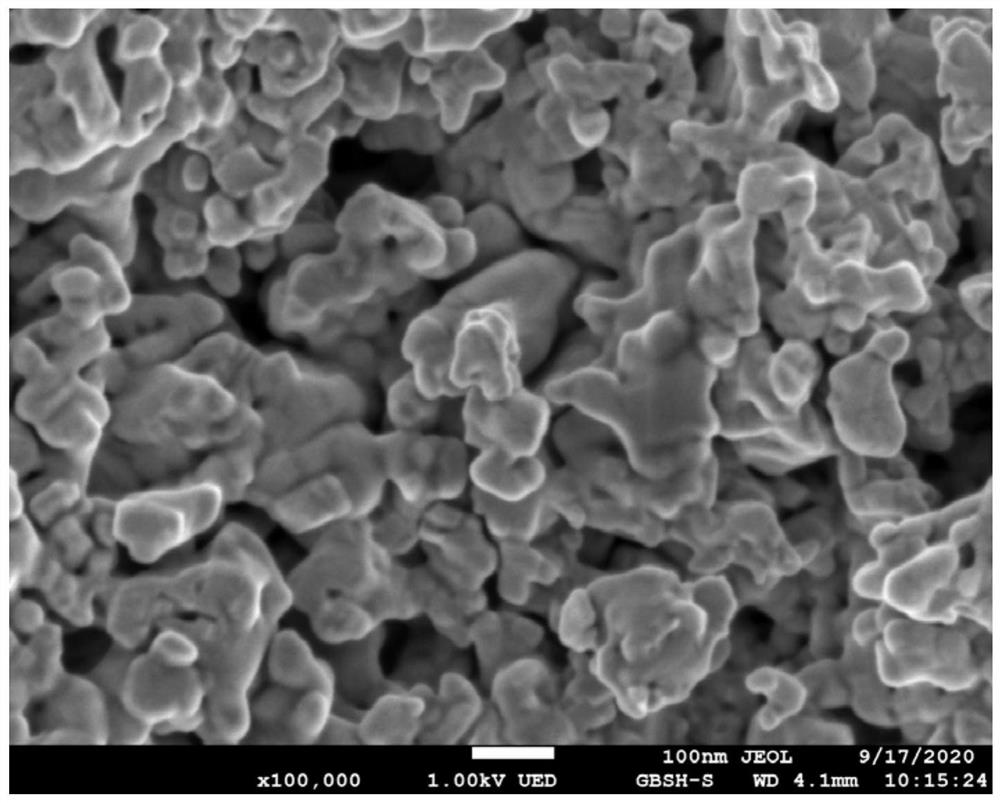

Embodiment 2

[0039] In this example, the high specific surface nano W powder and carbon black prepared in Example 1 are used as raw materials to prepare nano WC powder, and the process steps are as follows:

[0040] (1) Purge the mixing chamber of the roller ball mill with argon gas of 600ml / min to discharge the air in the mixing chamber to prevent spontaneous combustion during mixing;

[0041](2) by WC chemical formula, the mass ratio of C and W is 12:184, and the percentage of ratio is 6.52%, and promptly the mass fraction of required carbon amount is 6.52%; Due to the prepared high specific surface nanometer W powder of embodiment 1 The oxygen content is 1.2%, so the mass fraction of W is 98.8%, and the corresponding mass fraction of C is 6.52%×98.8%=6.44%. The amount of deoxygenated carbon is calculated by completely generating CO from the oxygen in the raw material W powder, that is, 1g Oxygen needs 0.75g of carbon, so the mass fraction of oxygen-removing carbon is 1.2%×75%=0.9%, and ...

Embodiment 3

[0047] In this example, nano-WC powder was prepared from the high-specific-surface nano-W powder and anhydrous glucose prepared in Example 1. The process steps are as follows:

[0048] (1) Purge the mixing chamber of the roller ball mill with argon gas of 600ml / min to discharge the air in the mixing chamber to prevent spontaneous combustion during mixing;

[0049] (2) by WC chemical formula, the mass ratio of C and W is 12:184, and the percentage of ratio is 6.52%, and promptly the mass fraction of required carbon amount is 6.52%; Due to the prepared high specific surface nanometer W powder of embodiment 1 The oxygen content is 1.2%, so the mass fraction of W is 98.8%, and the corresponding mass fraction of C is 6.52%×98.8%=6.44%. The amount of deoxygenated carbon is calculated by completely generating CO from the oxygen in the raw material W powder, that is, 1g Oxygen needs 0.75g of carbon, so the mass fraction of oxygen-removing carbon is 1.2%×75%=0.9%, and the mass fraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com