Method for preparing wrinkle-free graphene film

A graphene film, wrinkle-free technology, applied in the field of preparing wrinkle-free graphene film, can solve problems such as affecting graphene performance and application, reducing graphene mobility, etc., achieving easy control of experimental parameters, convenience for low-cost mass production, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

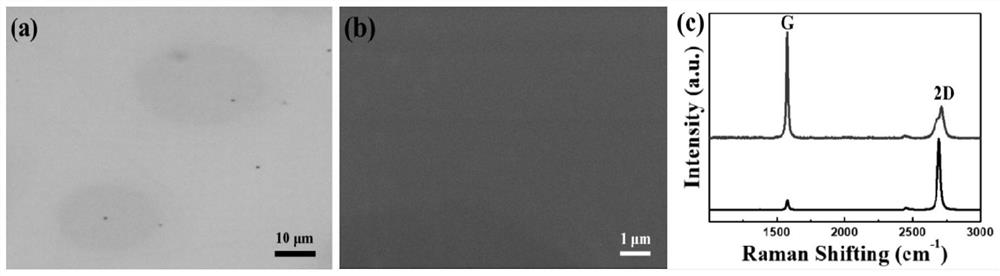

[0043] This embodiment discloses a method for preparing a wrinkle-free graphene film, which specifically includes the following steps:

[0044] S1. Cut 250 μm thick copper foil and 500 μm thick tungsten foil into square substrates of suitable size and flatten them; in order to remove contaminants on the copper and tungsten surfaces, ultrasonically clean the substrates in acetone and ethanol for 15 min, respectively, and then Rinse repeatedly with deionized water and dry under nitrogen blowing;

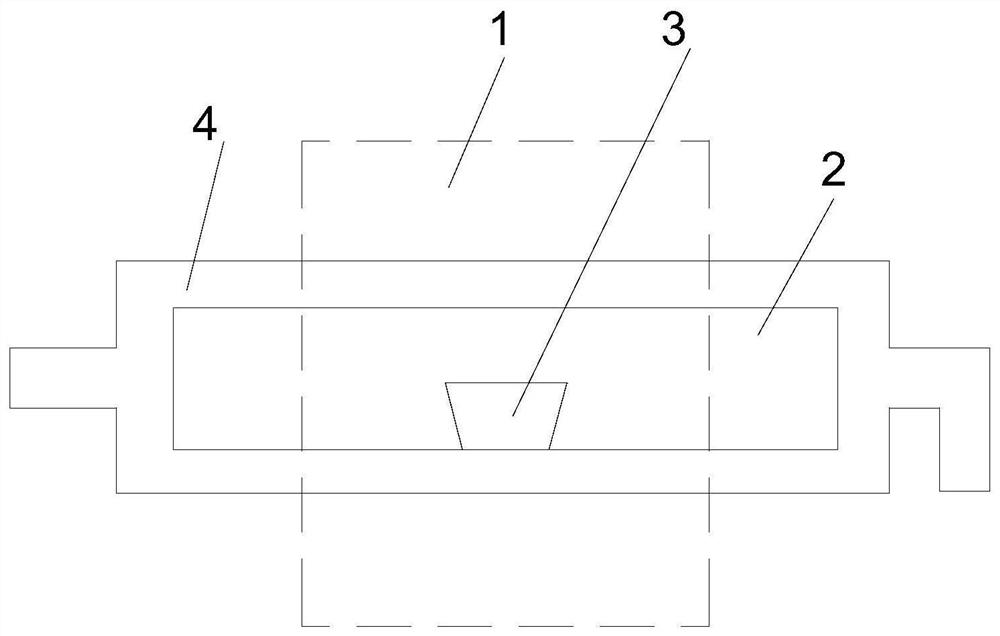

[0045] S2. Put the copper foil directly on the tungsten foil and push it into the heating area of the chemical vapor deposition system together, such as figure 1 As shown; before graphene growth, the whole system was evacuated to below 1.0Pa;

[0046] S3. Fill the quartz tube with hydrogen-argon mixed gas with a flow ratio of 1:20; then heat the system from room temperature to 1100°C within 60 minutes, and anneal at 1100°C for 30 minutes;

[0047] S4. Introduce 6 sccm methane into ...

Embodiment 2

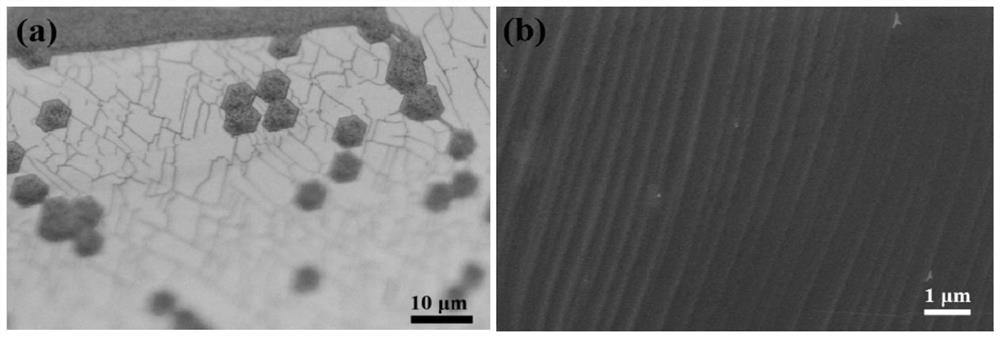

[0050] The difference between this embodiment and Embodiment 1 is that the flow ratio of the hydrogen-argon gas mixture in step S3 is changed to 1:15, and the other steps remain unchanged to obtain the sample to be tested.

Embodiment 3

[0052] The difference between this embodiment and Embodiment 1 is that the flow ratio of the hydrogen-argon gas mixture in step S3 is changed to 1:5, and the other steps remain unchanged to obtain the sample to be tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com