Preparation method of thallium-doped cesium iodide scintillation crystal and radiation detection panel

A scintillation crystal, cesium iodide technology, applied in radiation measurement, chemical instruments and methods, X/γ/cosmic radiation measurement, etc. Large and other problems, to achieve the effect of promoting low-cost mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

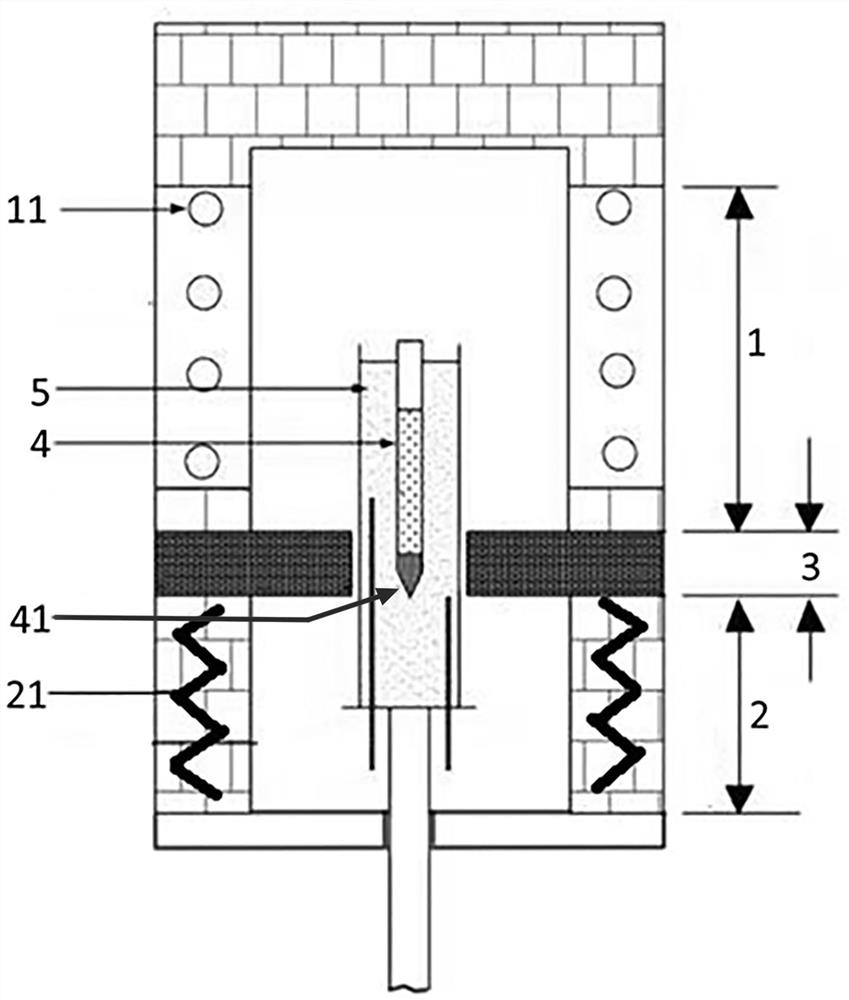

[0044] CsI:0.1 at% TlI crystals with a diameter of 330 mm were grown in a crystal growth furnace.

[0045] (1) Raw material preparation: thallium-doped cesium iodide crystal with Tl doping concentration of 0.1%. Using high-quality cesium iodide single crystal as the seed crystal, put the seed crystal into the narrowed section 41 at the bottom of the crucible 4 to prevent the seed crystal from shifting, then mix the raw materials into the platinum crucible, and put a lid on the top of the crucible 4 to prevent Impurities fall in. Among them, the weight of CsI (seed crystal + crystal block + powder) weighed is 49999.75 g, and the weight of TlI is 638.2 g.

[0046] (2) Crucible 4 loading: place the platinum crucible vertically in the insulation cover 5 of the crystal growth furnace and put it into the growth furnace, and the bottom of the platinum crucible is located in the crystallization area 3; Heating to a temperature of 200 °C, the vacuum degree reaches 4.5×10 -3 Pa, keep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com