A kind of concrete defoamer and preparation method thereof

A defoamer and concrete technology, which is applied in the field of building admixtures, can solve the problems of the decline of concrete mechanical properties and durability, and reduce the excellent bubble stability, so as to improve the foam control performance, excellent bubble stability, and improve the defoaming ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

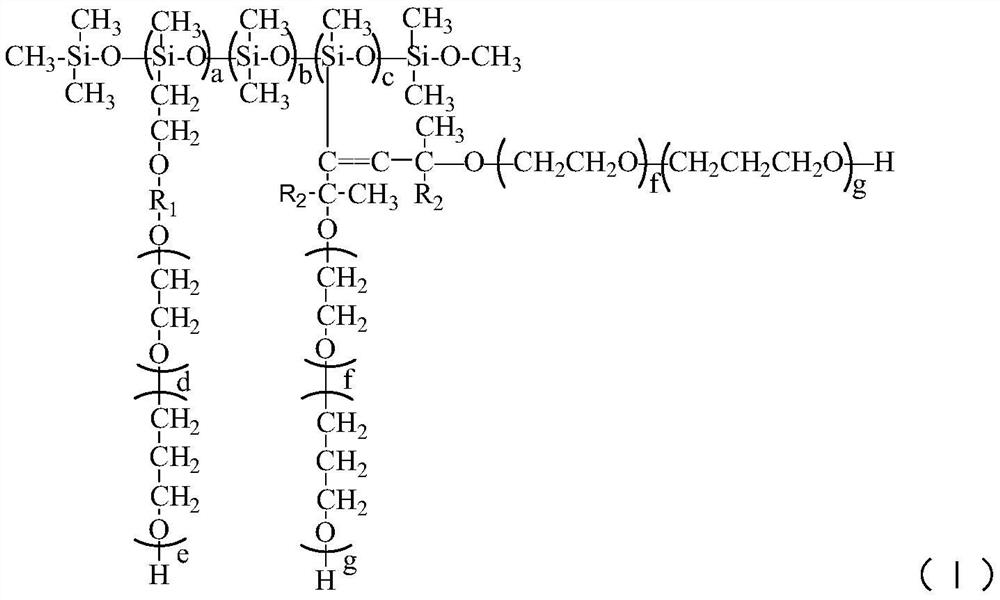

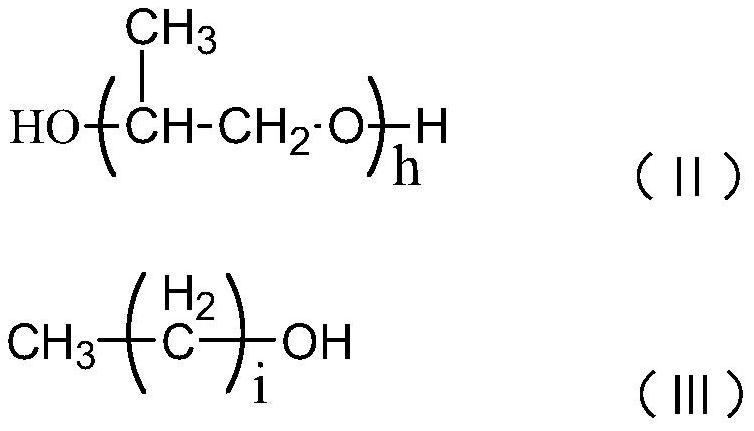

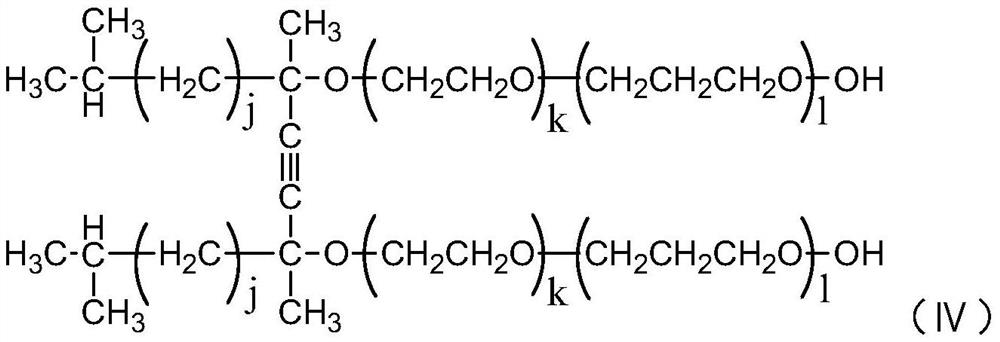

Method used

Image

Examples

Embodiment 1

[0083] Example 1 and the proportional 2, Example 2 and the proportion 3 show that alkyne glycol has reduced the surface tension of the aqueous system, and exhibits better defoaming; the integration of ethoxylated groups in the alkyne glycol molecule can increase the molecular water solubility, improve the foam control ability, good foam inhibition, but reduce the efficiency of surface tension decreased, poor defoaming.

[0084] The concrete defoamer provided by the present invention through the compounding of the defoamer, can give full play to the synergistic effect of each component, significantly improve the defoaming ability to prevent foam generation, while maintaining excellent bubble stability, maintaining beneficial small bubbles, has a certain anti-foaming performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com