High-temperature-resistant PP lunch box and manufacturing process thereof

A technology of high temperature resistance and lunch box, applied in the field of plastic product processing, can solve the problems of easy heat penetration, large gap, toxicity, etc., and achieve the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

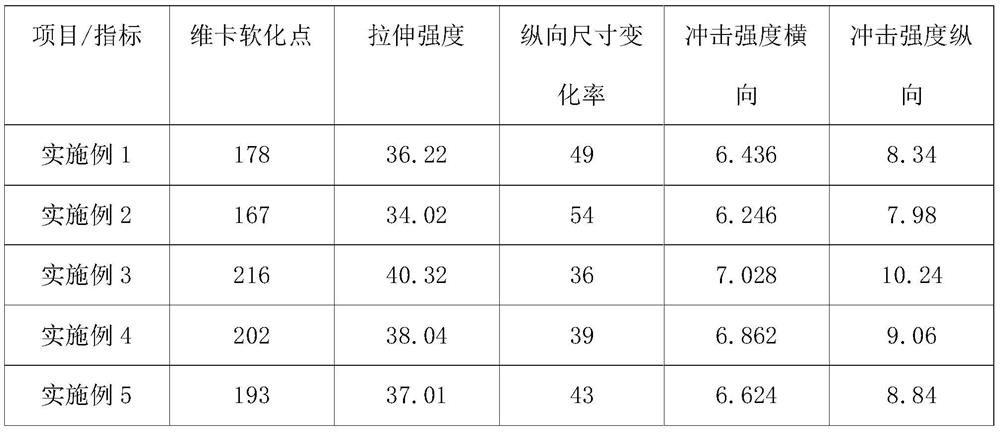

Examples

Embodiment 1

[0019] A high-temperature-resistant PP lunch box, characterized in that it comprises the following raw materials: 70 parts of polypropylene, 30 parts of PC, 20 parts of nano-calcium carbonate, 4 parts of talcum powder, 4 parts of carbon black, 2 parts of stearic acid, and 6 parts of silicon micropowder , 6 parts of mica powder, 6 parts of lithopone, 4 parts of azodicarbonamide, 1 part of zinc borate, 2 parts of maleic anhydride; 0.4 part of plasticizer, 0.4 part of flame retardant, 0.4 part of anti-aging agent and antioxidant 0.2 part of agent; all raw materials are calculated by weight;

[0020] The plasticizer includes TBC and ATBC, and the raw material ratio of TBC and ATBC is 1:1; the flame retardant includes red phosphorus and aluminum hydroxide, and the raw material ratio of red phosphorus and aluminum hydroxide is 1:1 ;

[0021] The antioxidant includes antioxidant 264 and phenolic antioxidant, and the raw material ratio of antioxidant 264 and phenolic antioxidant is 1...

Embodiment 2

[0027] A high-temperature-resistant PP lunch box, characterized in that it comprises the following raw materials: 90 parts of polypropylene, 60 parts of PC, 40 parts of nano-calcium carbonate, 8 parts of talcum powder, 8 parts of carbon black, 6 parts of stearic acid, and 10 parts of silicon micropowder , 8 parts of mica powder, 10 parts of lithopone, 6 parts of azodicarbonamide, 4 parts of zinc borate, 6 parts of maleic anhydride; 0.8 parts of plasticizer, 0.8 parts of flame retardant, 0.8 parts of anti-aging agent and antioxidant 0.6 part of agent; All raw materials are calculated by weight;

[0028] The plasticizer includes TBC and ATBC, and the raw material ratio of TBC and ATBC is 1:1; the flame retardant includes red phosphorus and aluminum hydroxide, and the raw material ratio of red phosphorus and aluminum hydroxide is 1:1 ;

[0029] The antioxidant includes antioxidant 264 and phenolic antioxidant, and the raw material ratio of antioxidant 264 and phenolic antioxidan...

Embodiment 3

[0035] A high-temperature-resistant PP lunch box, characterized in that it comprises the following raw materials: 80 parts of polypropylene, 45 parts of PC, 30 parts of nano-calcium carbonate, 6 parts of talcum powder, 6 parts of carbon black, 4 parts of stearic acid, and 8 parts of silicon micropowder , 7 parts of mica powder, 8 parts of lithopone, 5 parts of azodicarbonamide, 3 parts of zinc borate, 4 parts of maleic anhydride; 0.6 parts of plasticizer, 0.6 parts of flame retardant, 0.6 parts of anti-aging agent and antioxidant 0.4 part; all raw materials are calculated by weight;

[0036] The plasticizer includes TBC and ATBC, and the raw material ratio of TBC and ATBC is 1:1; the flame retardant includes red phosphorus and aluminum hydroxide, and the raw material ratio of red phosphorus and aluminum hydroxide is 1:1 ;

[0037] The antioxidant includes antioxidant 264 and phenolic antioxidant, and the raw material ratio of antioxidant 264 and phenolic antioxidant is 1:1; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com