Aggregation-induced emission polymer nanoparticles as well as preparation method and application thereof

A technology of aggregation-induced luminescence and nano-particles, which is applied in nanotechnology, nanotechnology, nano-optics, etc., can solve the problems of low synthesis efficiency and achieve the effects of simple operation, good uniformity and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Weigh 0.05 g of sodium lauryl sulfate, dissolve it in 12.5 g of water, and use it as an aqueous emulsifier solution for the continuous phase.

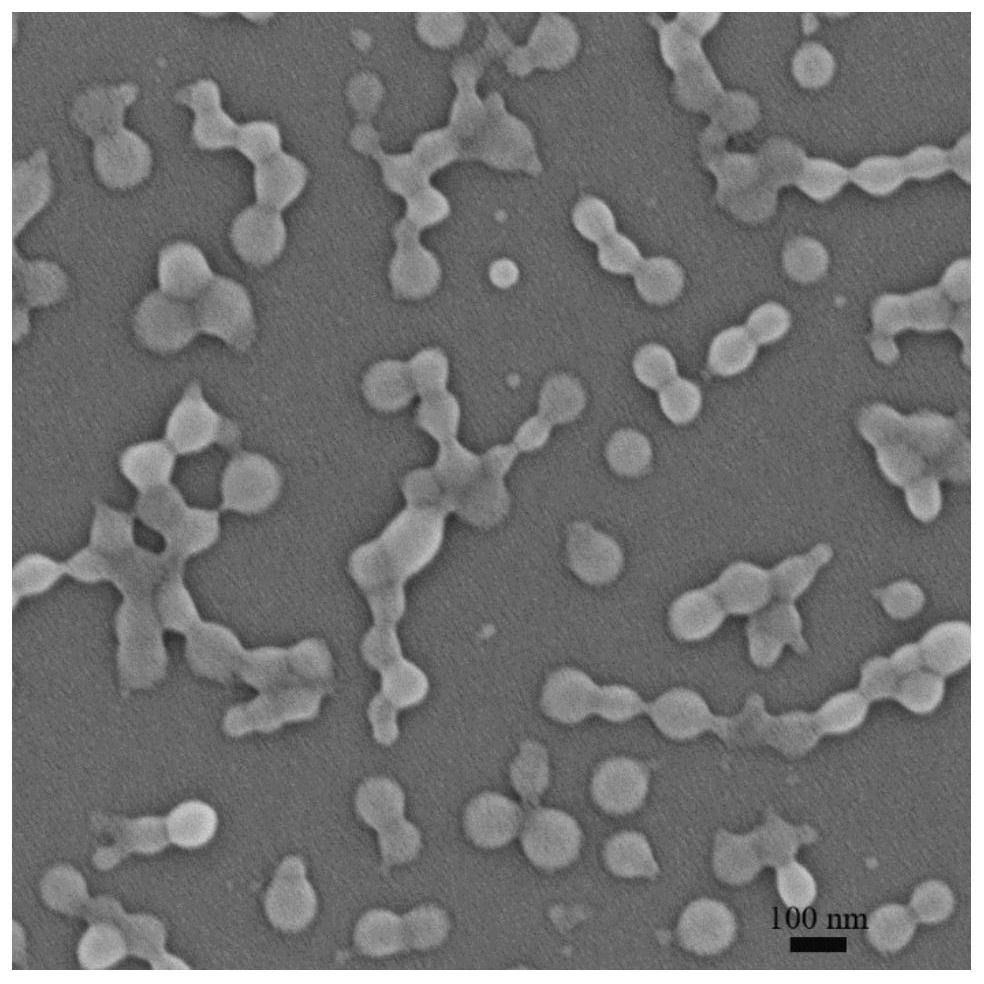

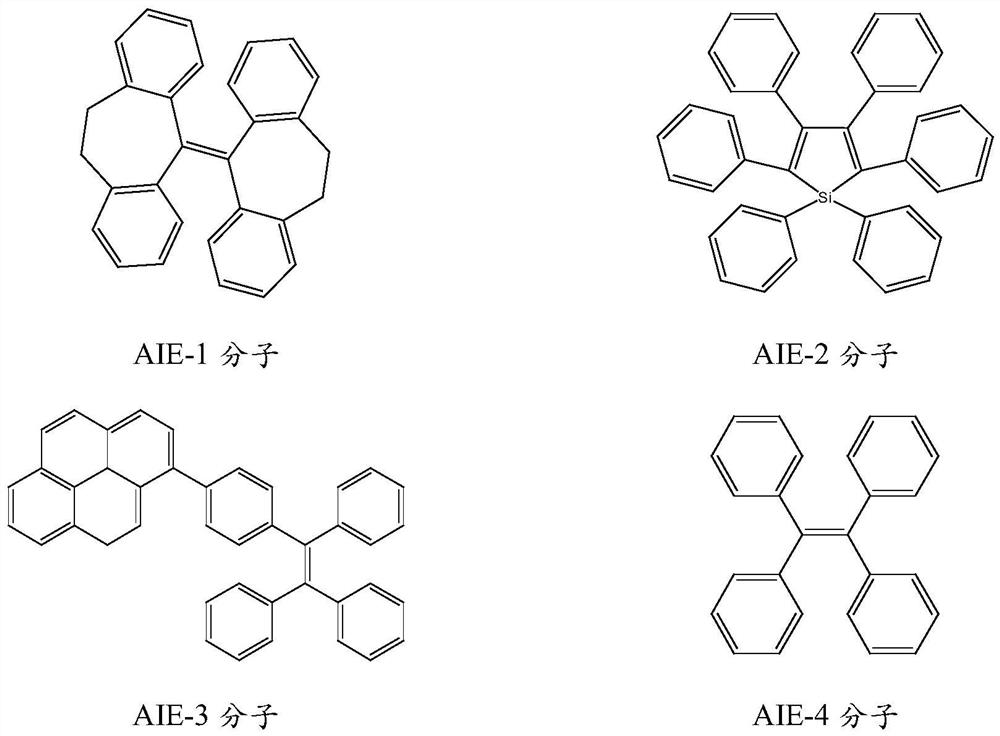

[0045] Dissolve 0.001 g of AIE-14 molecule, 0.06 g of n-hexadecane, and 0.1 g of polymethyl methacrylate in 4 mL of dichloromethane solvent as an oily solution of the dispersed phase. The two solutions were mixed and pre-emulsified in a water bath for 15 min under magnetic stirring at 700 rpm to obtain a coarse emulsion. The coarse emulsion was ultrasonicated for 10 min in an ice-water bath, the ultrasonic power was 400 W, and the pulse sequence was 12 s on, 6 s in interval to obtain stable fine emulsion droplets. Put the AIE polymer nanoparticle emulsion into a rotary evaporator, remove the solvent solvent under a low-pressure environment, and obtain the AIE polymer nanoparticle emulsion. The emulsion was centrifuged, and then redispersed in water, and this method was circulated three times to obtain purified AIE polymer nanop...

Embodiment 2

[0048] Weigh 0.2 g of cetyltrimethylammonium chloride, dissolve it in 50 g of water, and use it as the aqueous emulsifier solution of the continuous phase.

[0049] 0.004 g of AIE-18 molecule, 0.04 g of n-hexadecane, and 0.4 g of poly(lactic-co-glycolic acid) were dissolved in 16 mL of ethyl acetate solvent as an oily solution of the dispersed phase. The two solutions were mixed and pre-emulsified in a water bath for 15 min under magnetic stirring at 700 rpm to obtain a coarse emulsion. The coarse emulsion was ultrasonicated for 8 minutes in an ice-water bath, the ultrasonic power was 450W, and the pulse sequence was 12s working and 6s interval to obtain stable fine emulsion droplets. Put the AIE polymer nanoparticle emulsion into a rotary evaporator, remove the solvent solvent under a low-pressure environment, and obtain the AIE polymer nanoparticle emulsion. The emulsion was centrifuged, and then redispersed in water, and this method was circulated three times to obtain pur...

Embodiment 3

[0052] Weigh 2 g of polyvinyl alcohol, dissolve it in 100 g of water, and use it as the emulsifier aqueous solution of the continuous phase.

[0053] 0.008 g of AIE-6 molecules, 0.08 g of n-hexadecane, and 0.8 g of phospholipid polyethylene glycol maleimide were dissolved in 30 mL of chloroform solvent as an oily solution of the dispersed phase. The two solutions were mixed and pre-emulsified in a water bath for 15 min under magnetic stirring at 700 rpm to obtain a coarse emulsion. The coarse emulsion was ultrasonicated for 6 minutes in an ice-water bath, the ultrasonic power was 500W, and the pulse sequence was 12s working and 6s interval to obtain stable fine emulsion droplets. Put the AIE polymer nanoparticle emulsion into a rotary evaporator, remove the solvent solvent under a low-pressure environment, and obtain the AIE polymer nanoparticle emulsion. The emulsion was centrifuged, and then redispersed in water, and this method was circulated three times to obtain purified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

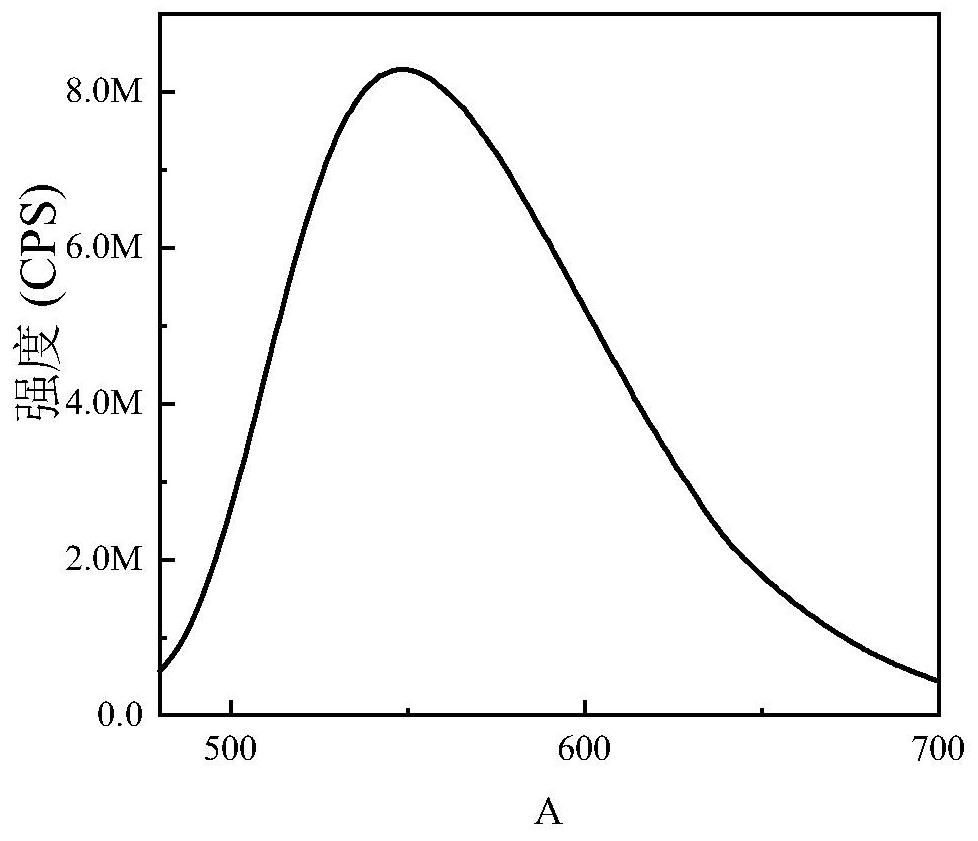

| Maximum emission wavelength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com