A carbon-based solid acid catalyst and its preparation method and its application to biomass hydrothermal conversion

A carbon-based solid acid and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of restricting large-scale industrial applications, reduced catalyst cycle performance, and limited number of active centers , to achieve the effects of facilitating large-scale production, improving catalytic performance, and making the preparation process green and environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention proposes a method for producing a carbon-based solid acid catalyst, pectin carbon-based precursor, the aromatic ring pectin matrix resin ion in a medium mixing dried, the dried resultant was subjected to pyrolysis, using concentrated sulfuric acid for sulfonation, to give a carbon-based solid acid catalyst. Includes the following steps:

[0051] S1. Pump with water, then activate sulfuric acid, and then adding the mixture into the ionic resin of the aromatic ring matrix;

[0052] S2. Dry the obtained obtained by step S1, the obtained material is pulverized into a powder, and the pyrolysis of the dry inert gas;

[0053] S3. The solid obtained after the heat solution of step S2 is subjected to sulfonation treatment;

[0054] S4. After the obtaining of step S3 is diluted with water, filtered, filtered, washed with water until the sulfate ion is no longer detected in the washing water;

[0055] S5. The solids obtained by filtration were dried.

[0056] Fur...

Embodiment 1

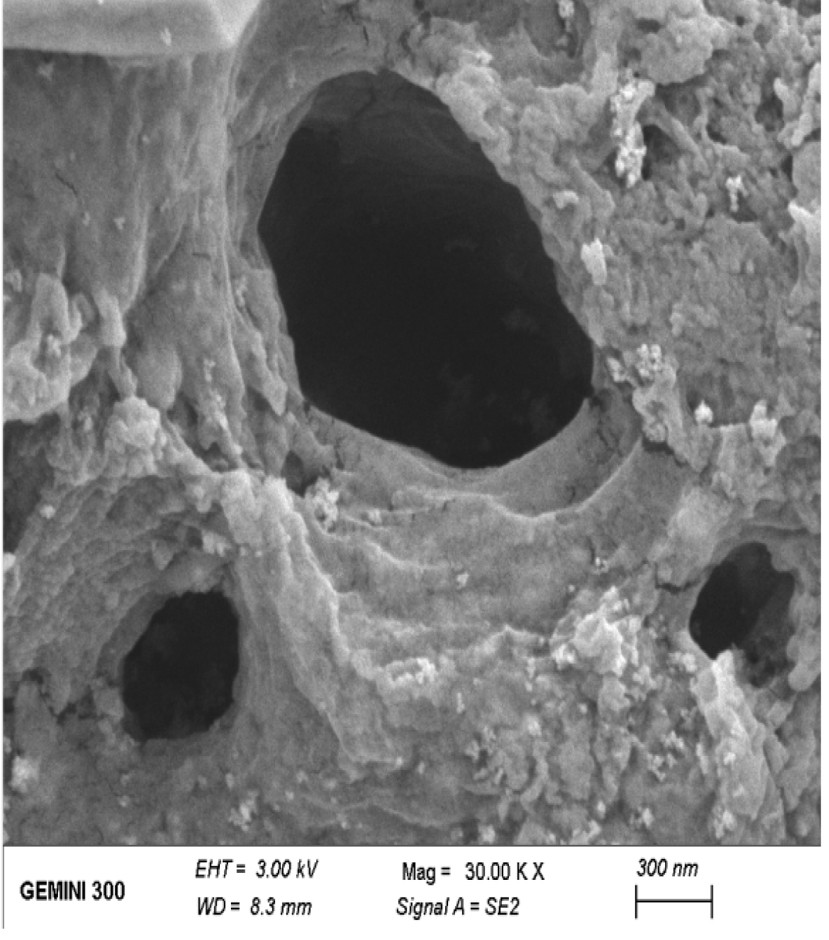

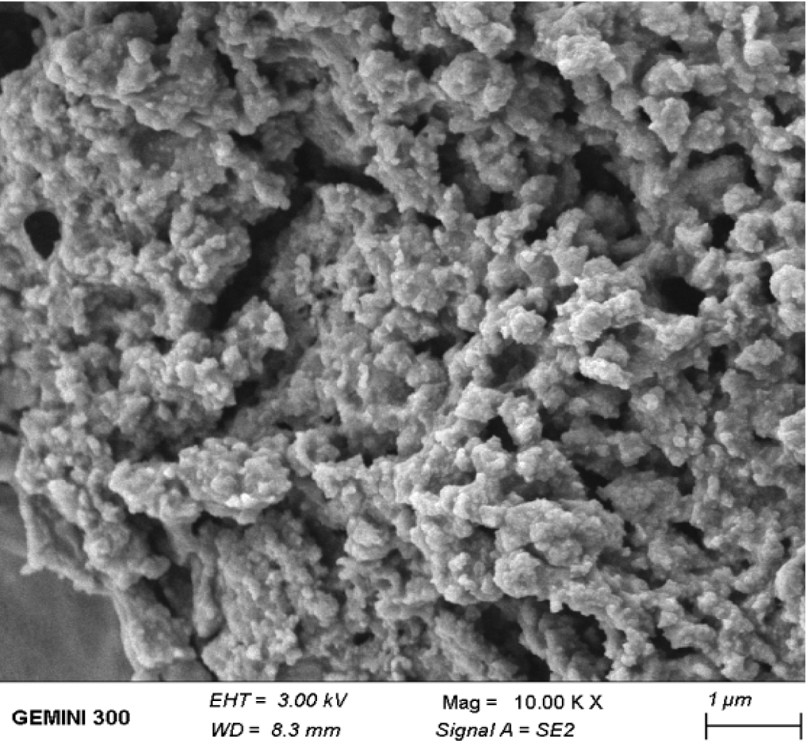

[0071] 8g dried orange peel pectin 30ml deionized water, was added 1ml of concentrated sulfuric acid (98%), and the mixture was slowly added to the pre-dried in 8g Amberlyst 15 ion exchange resin. At 110 ~ 120 ℃ dried 48 h, the resulting black material was dried at 300 deg.] C in a horizontal tube furnace nitrogen pyrolyzed 1 h. With concentrated sulfuric acid (1 g solid / 5g H 2 SO 4 ) Sulfonation at 24 h at 80 ℃, with magnetic stirring heating apparatus is an oil heating bath. After dilution with large amounts of deionized water, the black substance was collected by filtration, washed with deionized water several times, washed with water until sulfate ions are no longer detected. The resulting black solid was dried in an oven to 80 ° C for 24 hours. 0.05g of the resulting black solid was taken in 10ml test tube, was added 0.1g of xylose and 5mlγ- valerolactone, heating the reaction under microwave conditions IH, at a reaction temperature 140 ~ 180 ℃, furfural yields are higher t...

Embodiment 2

[0078] 8g dried orange peel pectin 30ml deionized water, was added 1ml of concentrated sulfuric acid (98%), and the mixture was slowly added to the pre-dried in 8g Amberlyst 15 ion exchange resin. At 110 ~ 120 ℃ dried 48 h, the resulting black material was dried at 300 deg.] C in a horizontal tube furnace nitrogen pyrolyzed 1 h. With concentrated sulfuric acid (1 g solid / 5g H 2 SO 4 ) Sulfonation at 24 h at 100 ℃, with magnetic stirring heating apparatus is an oil heating bath. After dilution with large amounts of deionized water, the black substance was collected by filtration, washed with deionized water several times, washed with water until sulfate ions are no longer detected. The resulting black solid was dried in an oven to 80 ° C for 24 hours. 0.05g of the resulting black solid was taken in 10ml test tube, was added 0.1g of xylose and 5mlγ- valerolactone, heating the reaction under microwave conditions IH, at a reaction temperature of 130 ℃, furfural yield 57.6mol.%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com