PDI/MOF heterojunction photocatalyst and preparation method and use method thereof

A photocatalyst and heterojunction technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve the problems of IOH waste water up to standard discharge, and achieve practical and feasible The effects of operability, mild preparation conditions and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

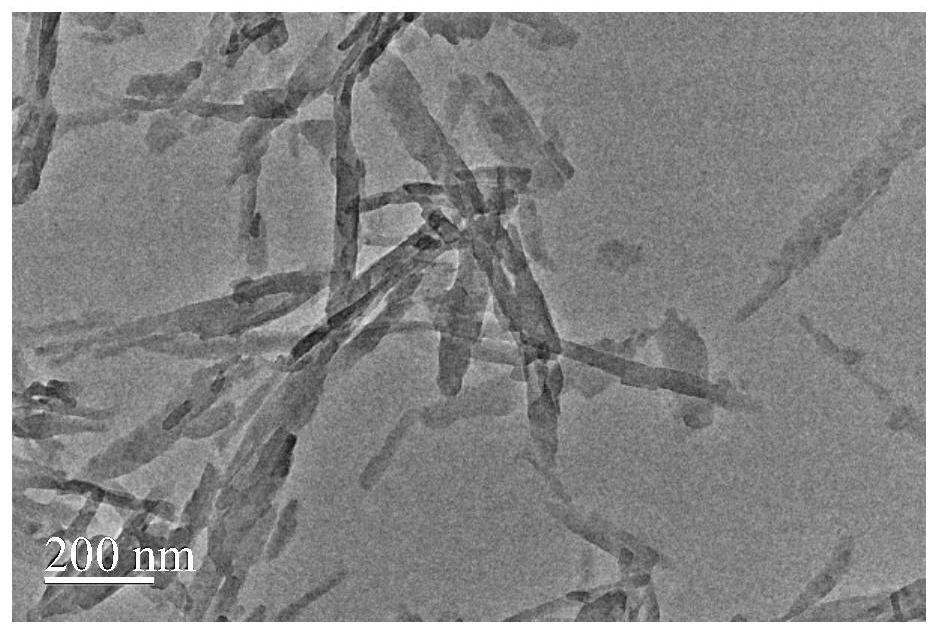

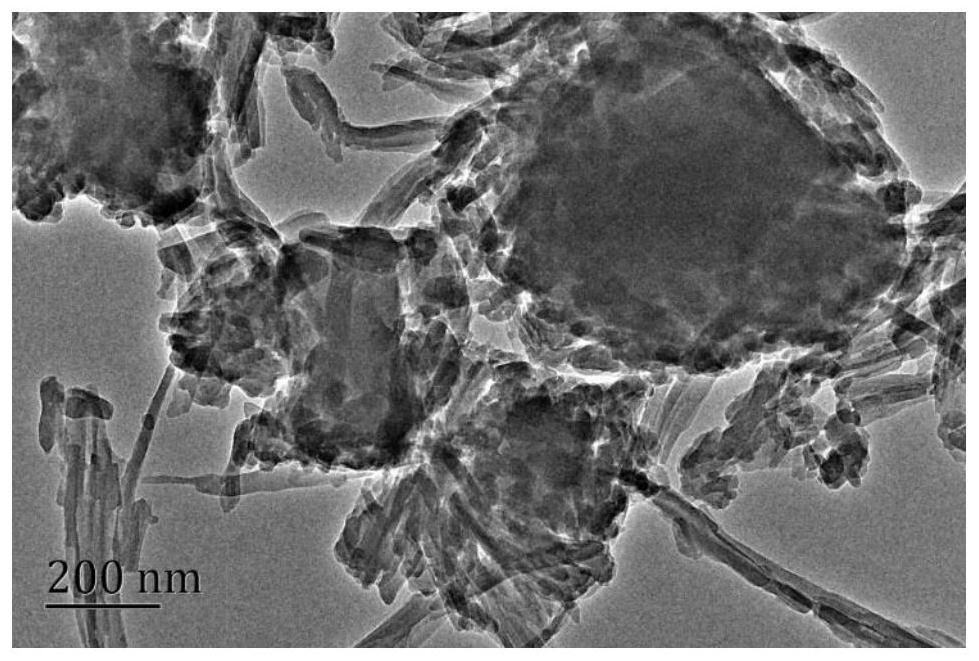

[0030] The PDI / MOF heterojunction photocatalyst of this embodiment is a PDI / MOF heterojunction photocatalyst activated persulfate system under visible light.

[0031] The preparation method of the PDI / MOF heterojunction photocatalyst of the present embodiment comprises the following steps:

[0032] (1) Put perylene-3,4,9,10-tetracarboxylic dianhydride, β-alanine and imidazole at a mass ratio of 1:1.8:10 in a four-necked flask under a nitrogen atmosphere at a temperature of 110°C Organic synthesis, adding ethanol and HCl at a mass ratio of 150:18 and stirring to obtain a stirred product;

[0033] (2) Filtrating and washing the stirred product to neutrality and drying to obtain PDI powder, wherein the filter membrane pore size is 0.22 μm, and the drying temperature is 60° C.;

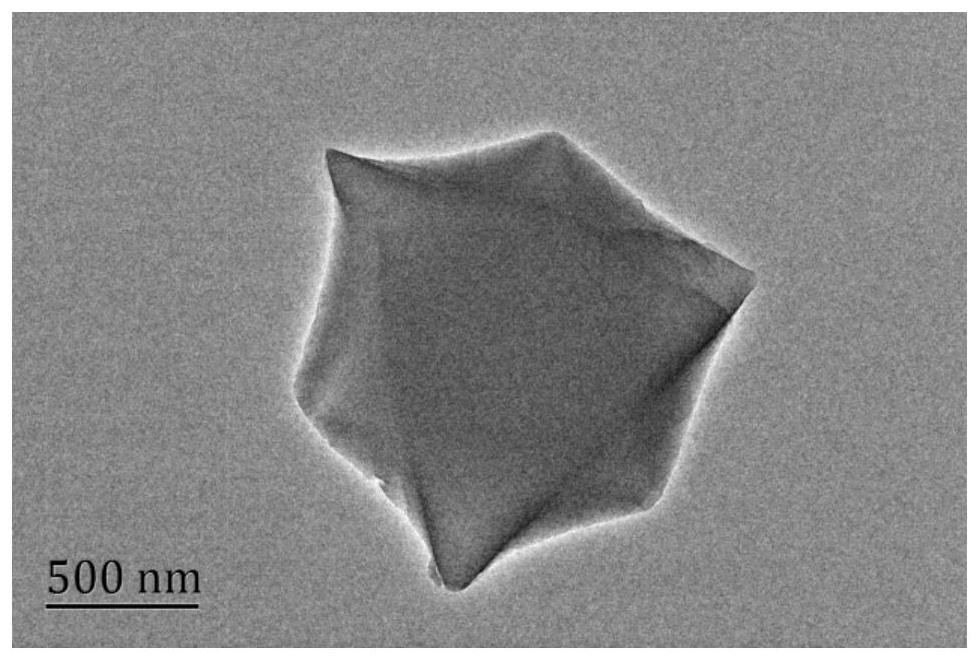

[0034] (3) Vacuum activation of MIL-101 (Cr) material at 150°C;

[0035] (4) Prepare 50mL PDI stock solution, add triethylamine, stir for 30min, add MOF and then add 5mL HNO 3 solution, heated to 60°C ...

Embodiment 2

[0038] The PDI / MOF heterojunction photocatalyst of this embodiment is a PDI / MOF heterojunction photocatalyst activated persulfate system under visible light.

[0039] The preparation method of the PDI / MOF heterojunction photocatalyst of the present embodiment comprises the following steps:

[0040] (1) Put perylene-3,4,9,10-tetracarboxylic dianhydride, β-alanine and imidazole at a mass ratio of 1:1.8:10 in a four-necked flask under a nitrogen atmosphere at a temperature of 100°C Organic synthesis, adding ethanol and HCl at a mass ratio of 160:18 and stirring to obtain a stirred product;

[0041] (2) Filtrating, washing to neutrality and drying the stirred product to obtain PDI powder, wherein the filter membrane pore size is 0.45 μm, and the drying temperature is 50° C.;

[0042] (3) Vacuum activation of MIL-101 (Cr) material at 145°C;

[0043] (4) Prepare 50mL of PDI stock solution, add triethylamine, stir for 30min, add MOF and then add 3mL HNO 3 solution, heated to 60°C ...

Embodiment 3

[0046] The PDI / MOF heterojunction photocatalyst of this embodiment is a PDI / MOF heterojunction photocatalyst activated persulfate system under visible light.

[0047] The preparation method of the PDI / MOF heterojunction photocatalyst of the present embodiment comprises the following steps:

[0048] (1) Put perylene-3,4,9,10-tetracarboxylic dianhydride, β-alanine and imidazole at a mass ratio of 1:1.8:15 in a four-necked flask under a nitrogen atmosphere at a temperature of 105°C Organic synthesis, adding ethanol and HCl at a mass ratio of 155:18 and stirring to obtain a stirred product;

[0049] (2) Filtrating, washing to neutrality and drying the stirred product to obtain PDI powder, wherein the filter membrane pore size is 0.22 μm, and the drying temperature is 70° C.;

[0050] (3) Vacuum activation of MIL-101 (Cr) material at 155°C;

[0051] (4) Prepare 50mL of PDI stock solution, add triethylamine, stir for 30min, add MOF and then add 7mL HNO 3 solution, heated to 60°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com