High-entropy ceramic material and preparation method thereof

A ceramic material and high-entropy technology, applied in the field of high-entropy ceramic materials and their preparation, can solve problems such as difficult to achieve high-efficiency mass production, inability to realize mass production, complex preparation process, etc., to improve physical and mechanical properties, hardness High, good storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

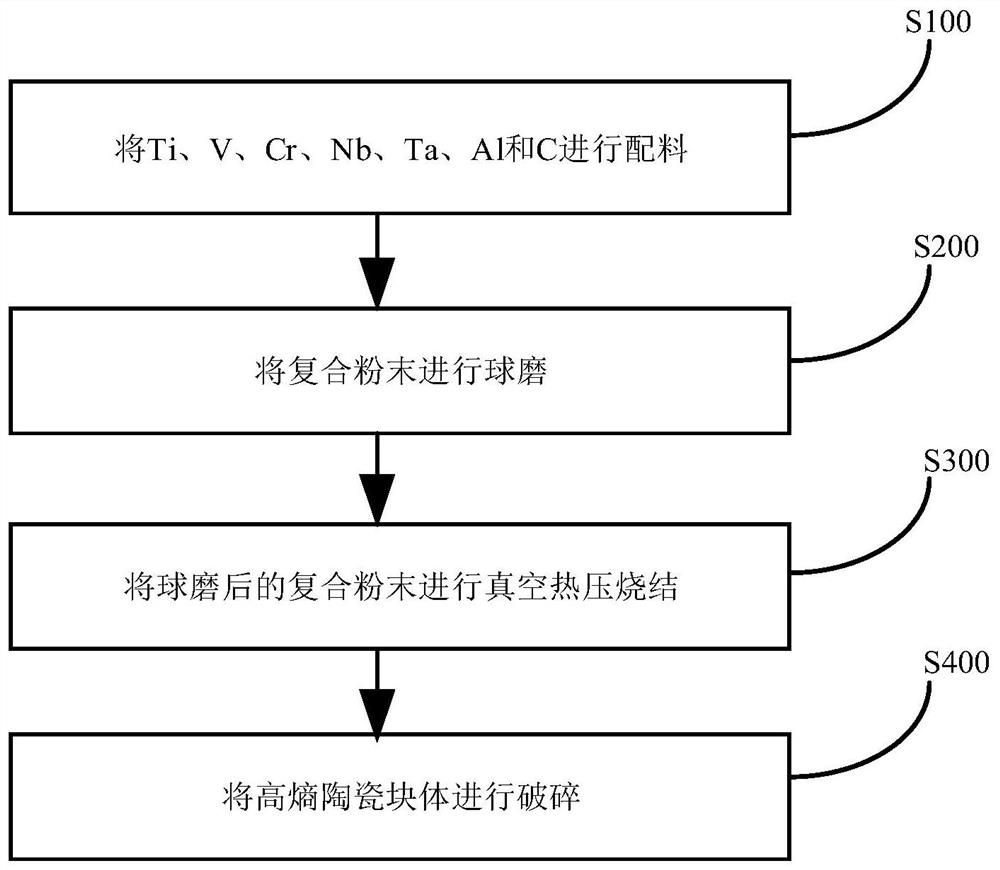

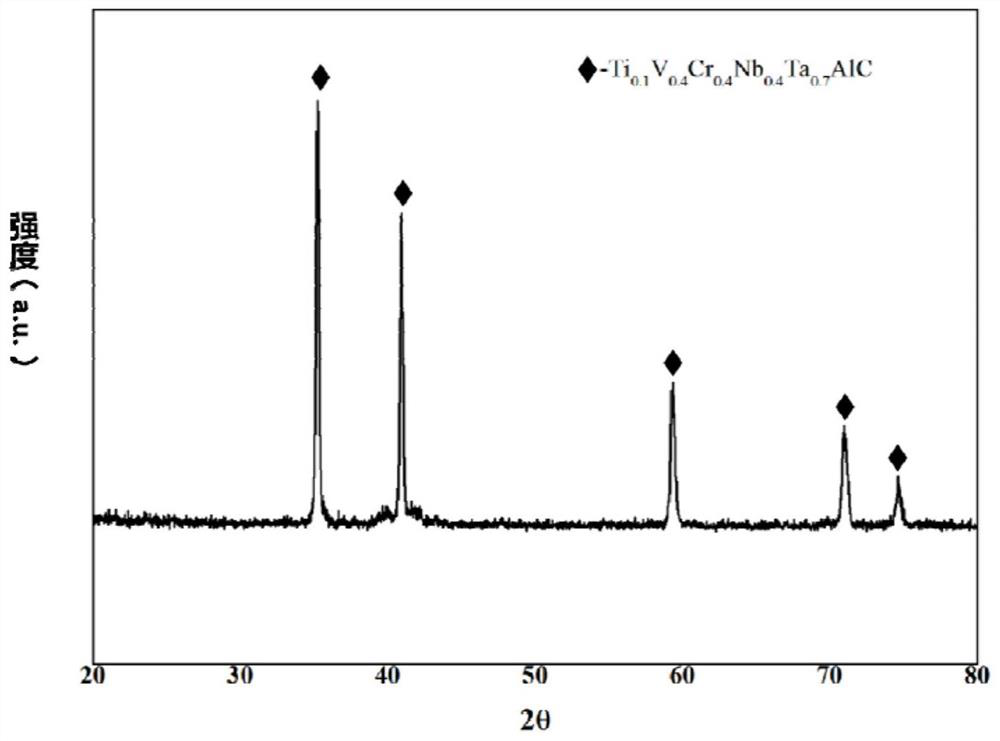

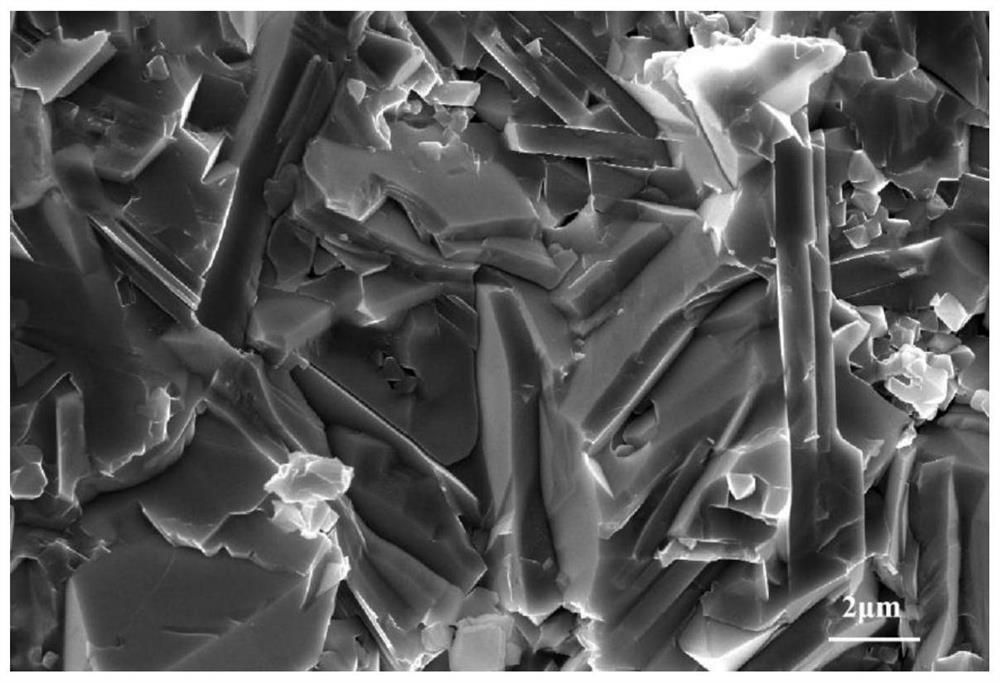

[0046] Step 1: Mix Ti, V, Cr, Nb, Ta, Al and C according to the ratio of the sum of the moles of Ti, V, Cr, Nb, Ta to the moles of Al and the moles of C as 2:1.1:1, wherein The molar numbers of Ti, V, Cr, Nb, Ta are 0.1, 0.4, 0.4, 0.4, 0.7 respectively;

[0047] Step 2: Place the composite powder in a ball mill tank under an argon protection environment for ball milling, the ball milling time is 2 hours, the ball milling speed is 300rmp, the ball-to-material ratio is 5:1, after mixing evenly, take out the composite powder and store it for later use;

[0048] Step 3: Lay the composite powder obtained in step 2 in the hot-press sintering furnace, and evacuate the hot-press sintering furnace, raise the temperature of the hot-press sintering furnace to 1500°C according to the predetermined heating rate of 10°C / min, and then pressurize to 10MPa , hold the pressure for 90 minutes, and reduce the pressure after the end of the heat preservation to obtain a high-entropy ceramic block; ...

Embodiment 2

[0052] Step 1: Mix Ti, V, Cr, Nb, Ta, Al and C according to the ratio of the sum of the moles of Ti, V, Cr, Nb, Ta to the moles of Al and the moles of C as 2:1.1:1, wherein The molar numbers of Ti, V, Cr, Nb, Ta are 0.3, 0.3, 0.4, 0.3, 0.6 respectively;

[0053] Step 2: Place the composite powder in a ball mill tank under an argon protection environment for ball milling, the ball milling time is 2 hours, the ball milling speed is 300rmp, the ball-to-material ratio is 5:1, after mixing evenly, take out the composite powder and store it for later use;

[0054] Step 3: Lay the composite powder obtained in step 2 in the hot-press sintering furnace, and vacuum the hot-press sintering furnace, raise the temperature of the hot-press sintering furnace to 1400°C according to the predetermined heating rate of 10°C / min, and then pressurize to 10MPa , hold the pressure for 120 minutes, and then reduce the pressure after the end of the heat preservation to obtain a high-entropy ceramic blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com