Matte organic silicon high-impact toughening agent and preparation method thereof

A silicone and high-impact technology, which is applied in the field of matte silicone high-impact toughening agent and its preparation, can solve the problems of high addition of matting agent, difficult processing, and great impact on product impact properties, and achieves Low production cost, convenient control and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

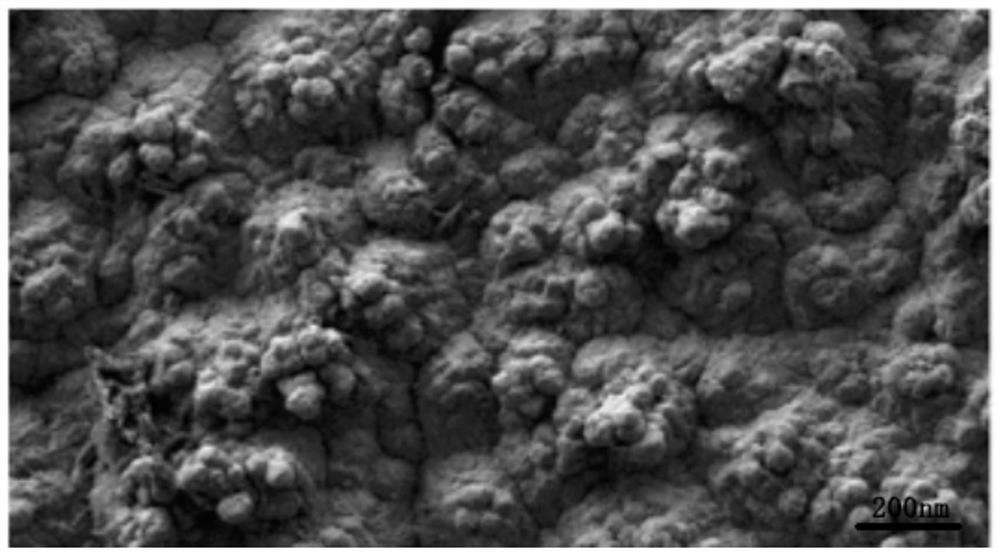

Image

Examples

Embodiment 1

[0039] A preparation method of a matt silicone high-impact toughening agent, comprising the steps of:

[0040] Synthetic organopolysiloxane core emulsion:

[0041] (S1), uniformly mixing the organosiloxane monomer and the silane coupling agent at a weight ratio of 100:7 to obtain the organosilicon mixture;

[0042] (S2), adding the organosilicon mixture into the aqueous solution mixed with the catalyst and emulsifier A, using a homogenizer to shear at a high speed of 10,000 rpm for 12 minutes, and then reacting at 90°C for 9 hours to obtain the organosilicon Polysiloxane core emulsion; Wherein, the total mass of the organosiloxane monomer is 40% of the water quality, the quality of the catalyst is 3% of the organosiloxane monomer quality, the emulsifier A The mass is 10% of the mass of organosiloxane monomer;

[0043] Synthetic Acrylate Rubber Emulsion:

[0044] (A1), mix 40 parts by weight of acrylate monomers and 1.2 parts by weight of crosslinking agent evenly, add 40 pa...

Embodiment 2

[0059] A preparation method of a matt silicone high-impact toughening agent, comprising the steps of:

[0060] Synthetic organopolysiloxane core emulsion:

[0061] (S1), uniformly mixing the organosiloxane monomer and the silane coupling agent at a weight ratio of 100:0.5 to obtain an organosilicon mixture;

[0062] (S2), adding the organosilicon mixture into the aqueous solution mixed with the catalyst and emulsifier A, using a homogenizer to shear at a high speed of 8000 rpm for 20 minutes, and reacting at a temperature of 85°C for 12 hours to obtain the organosilicon Polysiloxane core emulsion; Wherein, the total mass of the organosiloxane monomer is 20% of the water quality, the quality of the catalyst is 1% of the organosiloxane monomer quality, the emulsifier A The mass is 1% of the mass of organosiloxane monomer;

[0063] Synthetic Acrylate Rubber Emulsion:

[0064] (A1), mix 30 parts by weight of acrylate monomer and 0.15 parts by weight of crosslinking agent evenly...

Embodiment 3

[0079] A preparation method of a matt silicone high-impact toughening agent, comprising the steps of:

[0080] Synthetic organopolysiloxane core emulsion:

[0081] (S1), uniformly mixing the organosiloxane monomer and the silane coupling agent at a weight ratio of 100:15 to obtain an organosilicon mixture;

[0082] (S2), adding the organosilicon mixture into the aqueous solution mixed with the catalyst and emulsifier A, using a homogenizer to shear at a high speed of 12000 rpm for 5 minutes, and then reacting at 100°C for 6 hours to obtain the organosilicon Polysiloxane core emulsion; Wherein, the total mass of the organosiloxane monomer is 60% of the water quality, the quality of the catalyst is 5% of the organosiloxane monomer quality, the emulsifier A The mass is 20% of the organosiloxane monomer mass;

[0083] Synthetic Acrylate Rubber Emulsion:

[0084] (A1), mix 50 parts by weight of acrylate monomer and 2.5 parts by weight of cross-linking agent evenly, add 50 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com