A system for preparing antimony-free polyester melt and a method for preparing antimony-free polyester fine denier fdy fibers

An antimony-free polyester and preparation system technology is applied in the field of preparation of antimony-free polyester fine denier FDY fiber and antimony-free polyester melt preparation system, which can solve the problem of unsatisfactory spinning melt viscosity and catalytic polyester esterification rate. Slow, floating silk and other problems, to achieve excellent dyeing performance and mechanical properties, improve the speed of spinning, improve the effect of dyeing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

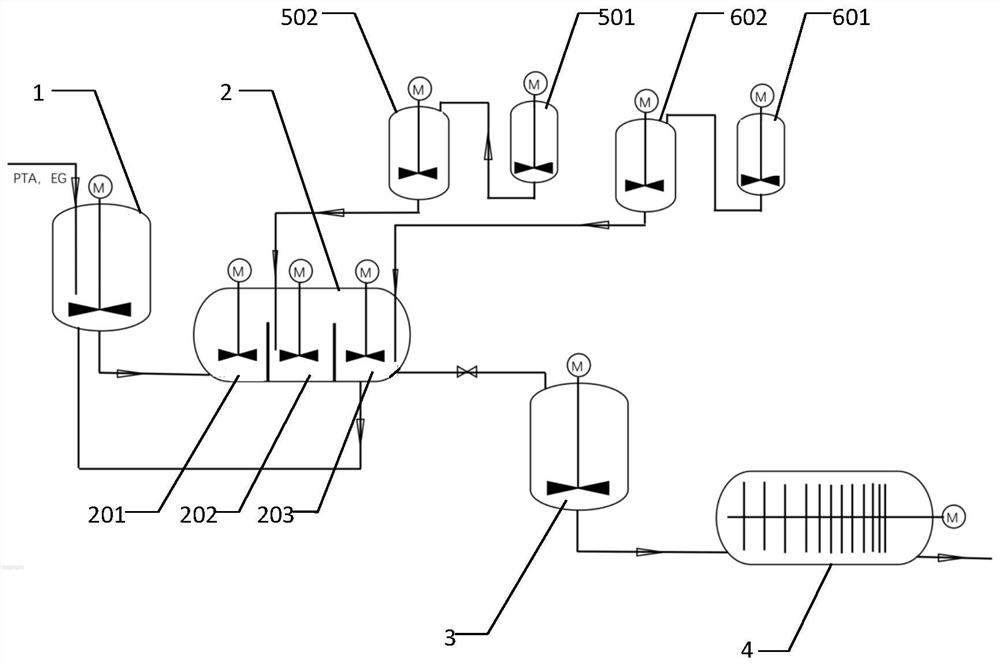

[0042] A method for preparing antimony-free polyester fine-denier FDY fibers by melt direct spinning, comprising the steps of:

[0043] (1) Add terephthalic acid, ethylene glycol and 2-pentyl-1,3 propanediol into the first esterification tank to carry out a primary esterification reaction, the mass ratio of terephthalic acid and ethylene glycol is 1:0.43, 2 - The addition of pentyl-1,3 propanediol accounts for 80ppm of the polyester mass; the reaction temperature is 245°C, the pressure is 300Kpa, and the residence time is 80min;

[0044] (2) Transport the primary esterification reaction product to the esterification I chamber in the second esterification tank, flow through the esterification II chamber and the esterification III chamber in turn, and add red to the esterification II chamber through the colorant supply tank. 2ppm blueness agent and 5ppm blueness agent, add 10ppm nano-titanium dioxide to the esterification III chamber through the catalyst supply tank to carry out...

Embodiment 2

[0049] A method for preparing antimony-free polyester fine-denier FDY fibers by melt direct spinning, comprising the steps of:

[0050] (1) Add terephthalic acid, ethylene glycol and 2-pentyl-1,3 propanediol into the first esterification tank to carry out a primary esterification reaction, the mass ratio of terephthalic acid and ethylene glycol is 1:0.43, 2 - The addition of pentyl-1,3 propanediol accounts for 80ppm of the polyester mass; the reaction temperature is 245°C, the pressure is 300Kpa, and the residence time is 80min;

[0051] (2) Transport the primary esterification reaction product to the esterification I chamber in the second esterification tank, flow through the esterification II chamber and the esterification III chamber in turn, and add red to the esterification II chamber through the colorant supply tank. 2ppm blueness agent and 5ppm blueness agent, add 10ppm heterogeneous titanium-based catalyst into the esterification III chamber through the catalyst supply...

Embodiment 3

[0061] A method for preparing antimony-free polyester fine-denier FDY fibers by melt direct spinning, comprising the steps of:

[0062] (1) Put terephthalic acid, ethylene glycol and 2-pentyl-1,4 butanediol into the first esterification tank to carry out an esterification reaction, the mass ratio of terephthalic acid and ethylene glycol is 1:0.48 , the amount of 2-pentyl-1,4-butanediol added accounted for 50ppm of the polyester mass; the reaction temperature was 248°C, the pressure was 100Kpa, and the residence time was 90min;

[0063] (2) Transport the primary esterification reaction product to the esterification I chamber in the second esterification tank, flow through the esterification II chamber and the esterification III chamber in turn, and add red to the esterification II chamber through the colorant supply tank. 2ppm blueness agent and 5ppm blueness agent, add 4ppm heterogeneous titanium-based catalyst into the esterification III chamber through the catalyst supply ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com