Weather-resistant high-temperature-resistant ultra-high molecular weight polyethylene fiber composite material and preparation method thereof

A technology of ultra-high molecular weight and polyethylene fiber, which is applied in the field of composite fiber materials, and can solve problems such as lack of weather resistance and high temperature resistance, materials that cannot be widely used, and material damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

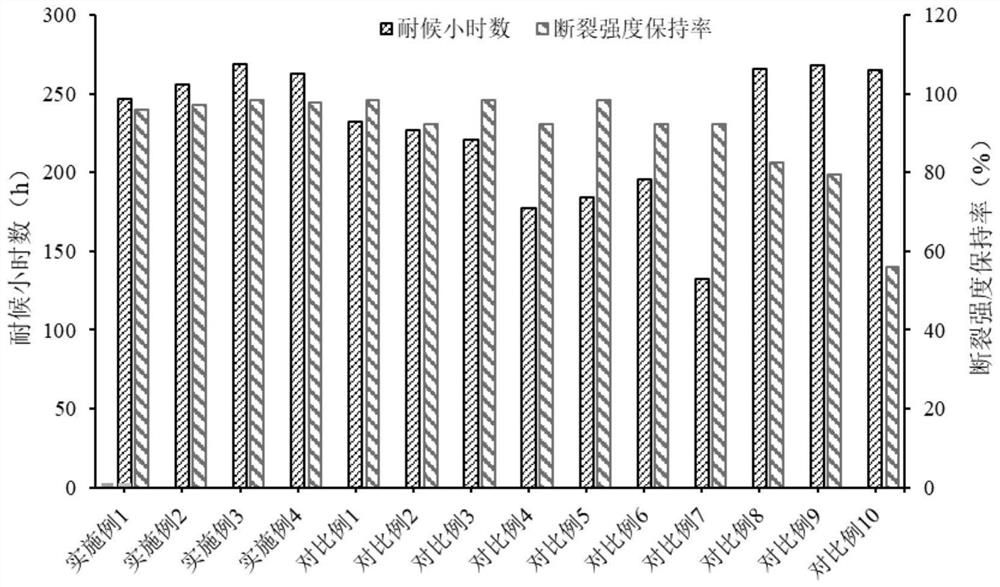

Examples

Embodiment 1

[0036] (1) According to the number of important parts, the raw materials are weighed as follows: 30 parts of ultra-high molecular weight polyethylene fiber, 15 parts of nitrile rubber, 12 parts of acrylate rubber, 10 parts of polyvinyl chloride, 4 parts of quartz sand, 5 parts of dolomite, 4 parts of cross-linking agent, 2 parts of plasticizer, 1 part of anti-aging agent, 2 parts of vulcanizing agent; plasticizer is phthalate diester, dioctyl phthalate and o- Dibutyl phthalate; cross-linking agent is sodium trimetaphosphate; anti-aging agent is anti-aging agent AW (6-ethoxy-2,2,4-trimethyl-1,2-quinoline dioxide); vulcanization The agent is sulfur;

[0037] (2) Add 12 parts of acrylate rubber, 4 parts of cross-linking agent, 2 parts of plasticizer, 1 part of anti-aging agent, and 2 parts of vulcanizing agent into the open mill, and blend at 85 ° C, 50 rpm minutes, stirred for 20 minutes, and obtained matrix A after blending;

[0038] (3) Add 15 parts of nitrile rubber and 10 ...

Embodiment 2

[0043](1) According to the number of important parts, the raw materials are weighed as follows: 35 parts of ultra-high molecular weight polyethylene fiber, 17 parts of nitrile rubber, 14 parts of acrylate rubber, 11 parts of polyvinyl chloride, 5 parts of quartz sand, 7 parts of dolomite, 6 parts of cross-linking agent, 3 parts of plasticizer, 1 part of anti-aging agent, 2 parts of vulcanizing agent; the plasticizer is phthalate diester, dioctyl phthalate and orthophthalate with a mass ratio of 1:1:1. Dibutyl phthalate; cross-linking agent is sodium trimetaphosphate; anti-aging agent is anti-aging agent AW (6-ethoxy-2,2,4-trimethyl-1,2-quinoline dioxide); vulcanization The agent is sulfur;

[0044] (2) Add 14 parts of acrylate rubber, 6 parts of crosslinking agent, 3 parts of plasticizer, 1 part of anti-aging agent, and 2 parts of vulcanizing agent into the open mill, and blend at 85 ° C, 50 rpm minutes, stirred for 20 minutes, and obtained matrix A after blending;

[0045] ...

Embodiment 3

[0050] (1) According to the number of important parts, the raw materials are weighed as follows: 40 parts of ultra-high molecular weight polyethylene fiber, 20 parts of nitrile rubber, 15 parts of acrylate rubber, 13 parts of polyvinyl chloride, 6 parts of quartz sand, 8 parts of dolomite, 7 parts of crosslinking agent, 4 parts of plasticizer, 2 parts of anti-aging agent, 3 parts of vulcanizing agent; plasticizer is phthalate diester, dioctyl phthalate and ortho Dibutyl phthalate; cross-linking agent is sodium trimetaphosphate; anti-aging agent is anti-aging agent AW (6-ethoxy-2,2,4-trimethyl-1,2-quinoline dioxide); vulcanization The agent is sulfur;

[0051] (2) Add 15 parts of acrylate rubber, 7 parts of cross-linking agent, 4 parts of plasticizer, 2 parts of anti-aging agent and 3 parts of vulcanizing agent into the open mill, and blend under the condition of 85 ℃, 50 rpm minutes, stirred for 20 minutes, and obtained matrix A after blending;

[0052] (3) Add 20 parts of n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com