PP composite material suitable for extruded sheet blistering and preparation method and application thereof

A technology of composite materials and antioxidants, applied in the field of PP composite materials and its preparation, can solve problems such as low melt strength, inability to maintain stability in the viscoelastic zone, easy aging, etc., and achieve compatibility problems and large market applications The effect of value and good workmanship requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

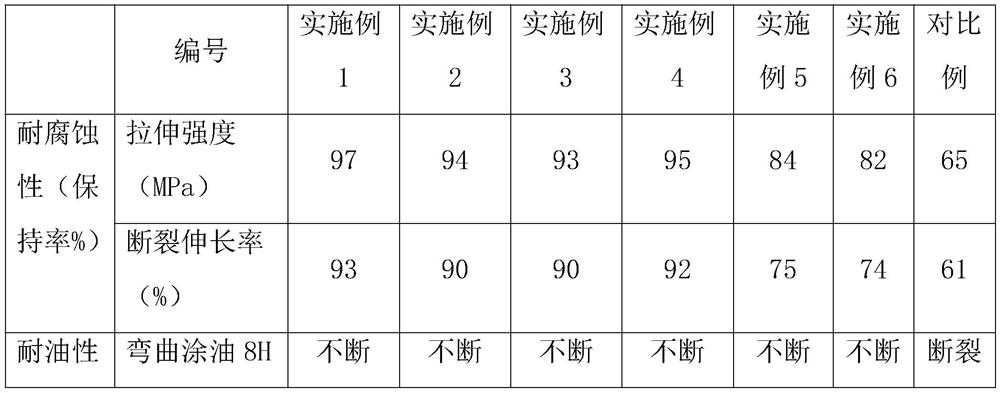

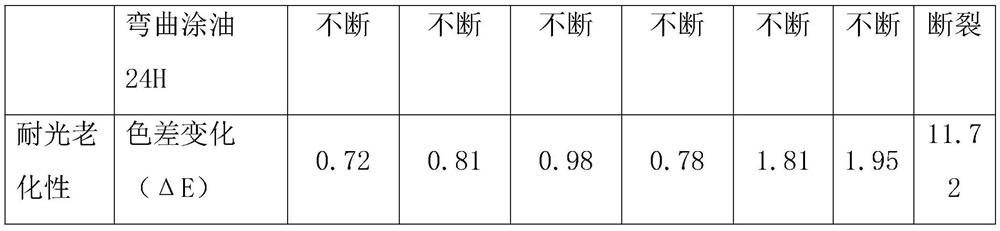

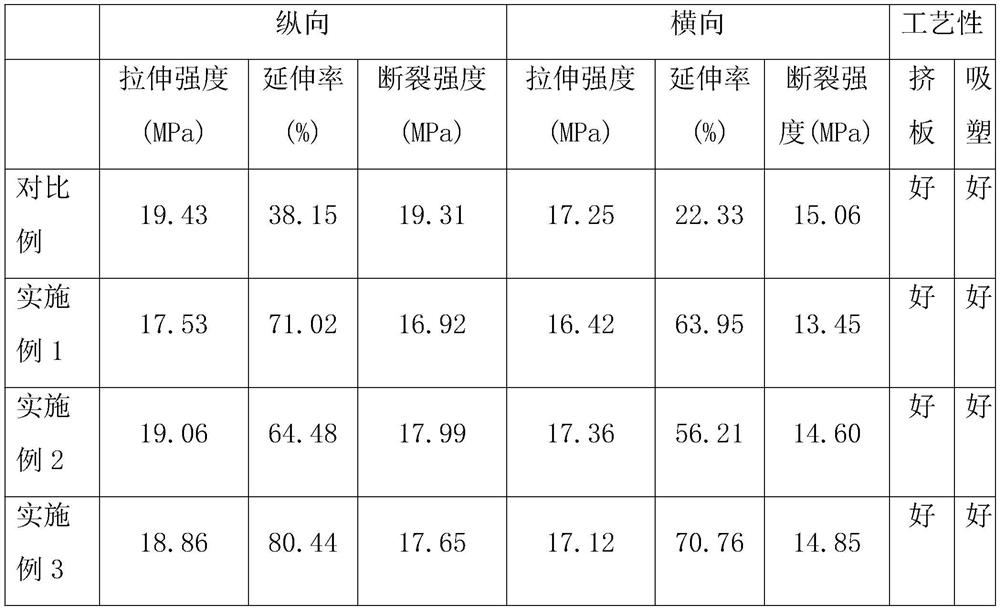

Examples

Embodiment 1

[0050] The preparation method of the PP compound material that is suitable for extruded plate blister, comprises the following steps:

[0051] (1) Homopolypropylene 60kg, polystyrene 13kg, DTBP (di-tert-butyl peroxide) 0.1kg, talcum powder 10kg, whiskers 10kg, antioxidant 1680.1kg, antioxidant 10100.3kg, SMA- 5.5kg of maleic anhydride was mixed homogeneously to obtain a mixture, and the mixing speed was 400rpm, and the mixing time was 5 minutes;

[0052] (2) Put the mixture into the twin-screw extruder through the main feed port. The temperature of each section of the twin-screw extruder is 170-180°C, 180-190°C, 190-200°C from the feed port to the machine head. °C, 200-210 °C, 200-210 °C, 210-220 °C, 210-220 °C, 200-210 °C, 200-210 °C, the screw speed is 300 rpm, and the product is obtained through melt extrusion and granulation.

Embodiment 2

[0054] The preparation method of the PP compound material that is suitable for extruded plate blister, comprises the following steps:

[0055] (1) Copolymerized polypropylene 50kg, high impact polystyrene 23kg, DTBP 0.1kg, talc powder 10kg, whiskers 10kg, antioxidant 1680.1kg, antioxidant 10760.3kg, compatibilizer SBS 5.5kg, stearin Calcium acid 1kg mixes evenly, obtains mixture, and mixing speed is 450rpm, and mixing time is 10 minutes;

[0056] (2) Put the mixture into the twin-screw extruder through the main feed port. The temperature of each section of the twin-screw extruder is 170-180°C, 180-190°C, 190-200°C from the feed port to the machine head. °C, 200-210 °C, 200-210 °C, 210-220 °C, 210-220 °C, 200-210 °C, 200-210 °C, the screw speed is 300 rpm, and the product is obtained through melt extrusion and granulation.

Embodiment 3

[0058] The preparation method of the PP compound material that is suitable for extruded plate blister, comprises the following steps:

[0059] (1) 25kg of homopolypropylene, 25kg of copolymerized polypropylene, 10kg of polystyrene, 23kg of high impact polystyrene, 0.1kg of DTBP, 5kg of talcum powder, 5kg of whiskers, 1680.2kg of antioxidant, 10100.1 of antioxidant kg, antioxidant 10760.1kg, compatibilizer SEBS 5.5kg, PE wax 0.5kg, silicone powder 0.5kg and mix evenly to obtain a mixture, the mixing speed is 500rpm, and the mixing time is 15 minutes;

[0060](2) Put the mixture into the twin-screw extruder through the main feed port. The temperature of each section of the twin-screw extruder is 170-180°C, 180-190°C, 190-200°C from the feed port to the machine head. °C, 200-210 °C, 200-210 °C, 210-220 °C, 210-220 °C, 200-210 °C, 200-210 °C, the screw speed is 400 rpm, and the product is obtained through melt extrusion and granulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com