Microcapsule phase change energy storage material and preparation method thereof

A phase change energy storage material and microcapsule technology, applied in microcapsule preparations, microsphere preparation, heat exchange materials, etc., can solve the problems of uneven thickness, decreased latent heat value of phase change, etc. Effect of improving flame retardancy and heat transfer performance, high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take 0.2g of sodium lauryl sulfate and 0.2g of octylphenol ethoxylate-10 and dissolve in 100g of deionized water, add 10g of paraffin, and react at 55°C and 800rpm for 25min to form a core material emulsion. Take 50 mL of 1 mol / L barium chloride aqueous solution, add it dropwise into the core material emulsion at 1.25 mL / min, stir and react at 55°C at 500 rpm for 3 h, and obtain a solid-liquid mixture. The resulting solid-liquid mixture was filtered, washed three times with a mixed solvent of deionized water and absolute ethanol with a mass ratio of 2:1, and dried at 50° C. for 24 hours to obtain a microcapsule phase-change energy storage material.

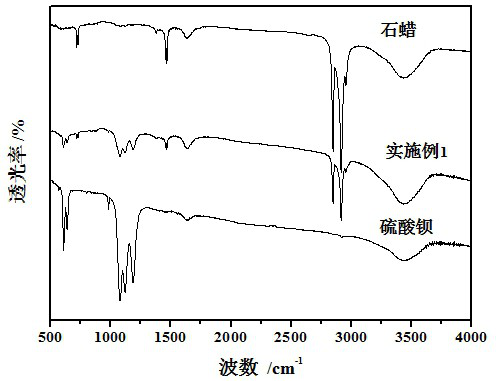

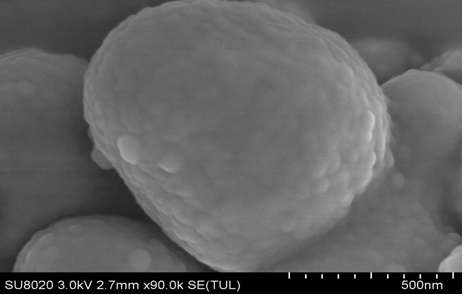

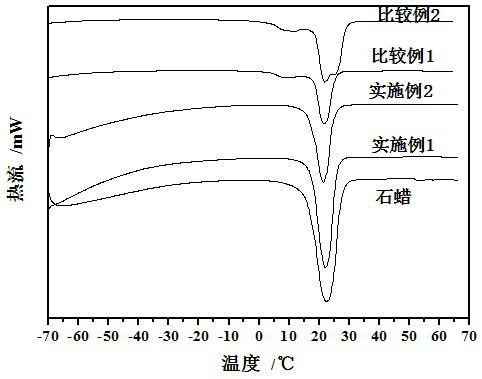

[0034] figure 1 The infrared spectrogram shows that in the infrared characteristic peaks of the sample of Example 1, the infrared characteristic peaks of the core material and the wall material appear simultaneously, that is, the coating effect of the microcapsule phase change energy storage material is good. Depend on f...

Embodiment 2

[0036]Take 0.15g of sodium lauryl sulfate and 0.15g of octylphenol ethoxylate-10 and dissolve them in 70g of deionized water, add 10g of paraffin, and react at 50°C and 700rpm for 20min to form a core material emulsion. Take 30 mL of 1 mol / L barium chloride aqueous solution, add it dropwise to the core material emulsion at 1 mL / min, and react at 50 ° C for 2 h at 400 rpm to obtain a solid mixture. The resulting solid-liquid mixture was filtered, washed three times with a mixed solvent of deionized water and absolute ethanol with a mass ratio of 2:1, and then the suction-filtered product was placed in a drying oven and dried at 45°C for 18 hours to obtain microcapsule phase transition energy storage materials.

Embodiment 3

[0038] Take 0.3g of sodium lauryl sulfate and 0.3g of octylphenol ethoxylate-10 and dissolve them in 120g of deionized water, add 10g of paraffin, and react at 55°C and 1000rpm for 30min to form a core material emulsion. Take 785mL of 1mol / L barium chloride aqueous solution, add it dropwise into the core material emulsion at 2mL / min, and react at 60°C and 600rpm for 4h to obtain a solid mixture. The resulting solid-liquid mixture was filtered, washed three times with a mixed solvent of deionized water and absolute ethanol with a mass ratio of 2:1, and then the suction-filtered resultant was placed in a drying oven and dried at 55°C for 26 hours to obtain microcapsule phase transition energy storage materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com