A kind of nano pressure-reducing and increasing-injection oil flooding and viscosity-reducing integrated agent and its preparation method and application

A nanometer and oil displacement technology, which is applied in chemical instruments and methods, production fluids, earth drilling and production, etc., can solve the problems of insufficient injection effect and difficulty in achieving low interfacial tension, so as to eliminate clogging, reduce surface interfacial tension, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

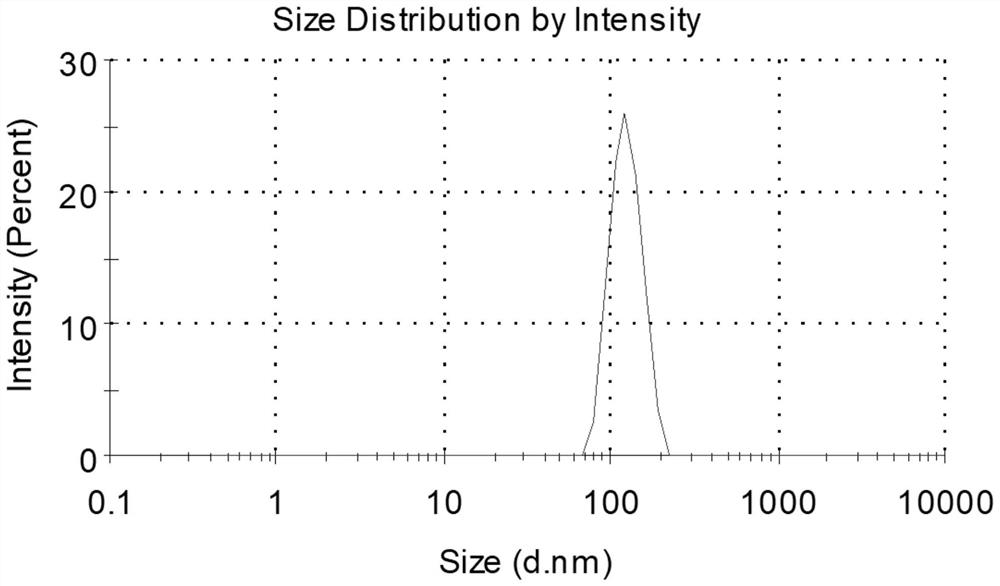

Image

Examples

preparation example Construction

[0032] The preparation method of the nano pressure-reducing and increasing-injection oil displacement and viscosity-reducing integrated agent of the present invention comprises the following processes:

[0033]Add oil-soluble comb polymer, triethylenetetraaminehexaacetic acid, dihexyltriaminepentamethylene phosphoric acid, cocamidopropyl sulfobetaine, xylene and dioctadecane in sequence in the reaction kettle Dimethyl ammonium chloride, nonylphenol polyoxyethylene ether TX-15 and water were stirred for 30 minutes, then monoethanolamine was added to react for 30 minutes, then methanol was added, and the nanometer pressure-reducing injection flooding and viscosity-reducing All in one.

[0034] The nano-scale pressure-reducing, increasing-injection, oil-flooding and viscosity-reducing integrated agent of the present invention is used in water injection well operations. When the nano-scale pressure-reducing, increasing-injection, oil-flooding and viscosity-reducing integrated agen...

Embodiment 1

[0036] This embodiment provides a nano-scale pressure-increasing injection flooding oil displacement and viscosity-reducing integrated agent. The raw material composition of the nano-scale pressure-increasing injection oil flooding and viscosity-reducing integrated agent includes 10% polyethylene terephthalic acid di-p-methoxy Phenyl Esters, 10% Triethylenetetraminehexaacetic Acid, 10% Dihexyltriamine Pentamethylene Phosphate, 10% Monoethanolamine, 10% Cocamidopropyl Mestaine, 25% xylene, 5% dioctadecyldimethylammonium chloride, 15% nonylphenol polyoxyethylene ether TX-15, 20% methanol, and the balance is water.

[0037] This embodiment also provides a preparation method of the above-mentioned nano-scale pressure-reducing and increasing-injection oil flooding and viscosity-reducing integrated agent, which specifically includes the following steps:

[0038] Add polyvinyl di-p-methoxyphenyl terephthalate, triethylenetetraminehexaacetic acid, dihexamethylene triamine pentamethyle...

Embodiment 2

[0056] This embodiment provides a nano-scale pressure-increasing injection flooding oil flooding and viscosity-reducing integrated agent. The raw material composition of the nano-scale pressure-increasing injection oil flooding and viscosity-reducing integrated agent includes 8% polyvinyl terephthalic acid di-p-methoxy Phenyl esters, 8% triethylenetetraminehexaacetic acid, 9% dihexyltriaminepentamethylene phosphate, 9% monoethanolamine, 9% cocamidopropyl mestaine, 23% xylene, 4% dioctadecyldimethylammonium chloride, 13% nonylphenol polyoxyethylene ether TX-15, 18% methanol, and the balance is water.

[0057] The performance of the above-mentioned integrated agent of this embodiment was tested indoors. Its quality technical indicators are as follows:

[0058] Appearance: Colorless transparent liquid at room temperature;

[0059] pH value: 7.1;

[0060] Anti-expansion rate 65%;

[0061] Shrinkage rate 33%;

[0062] Calcium sulfate scale inhibition rate is 93%;

[0063] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com