Organic semiconductor film and preparation method thereof

A technology of organic semiconductor and thin film, which is applied in the field of organic semiconductor thin film and its preparation, can solve the problems such as the decrease of fluorescence intensity, and achieve the effects of avoiding contradictions, improving solution processing performance, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

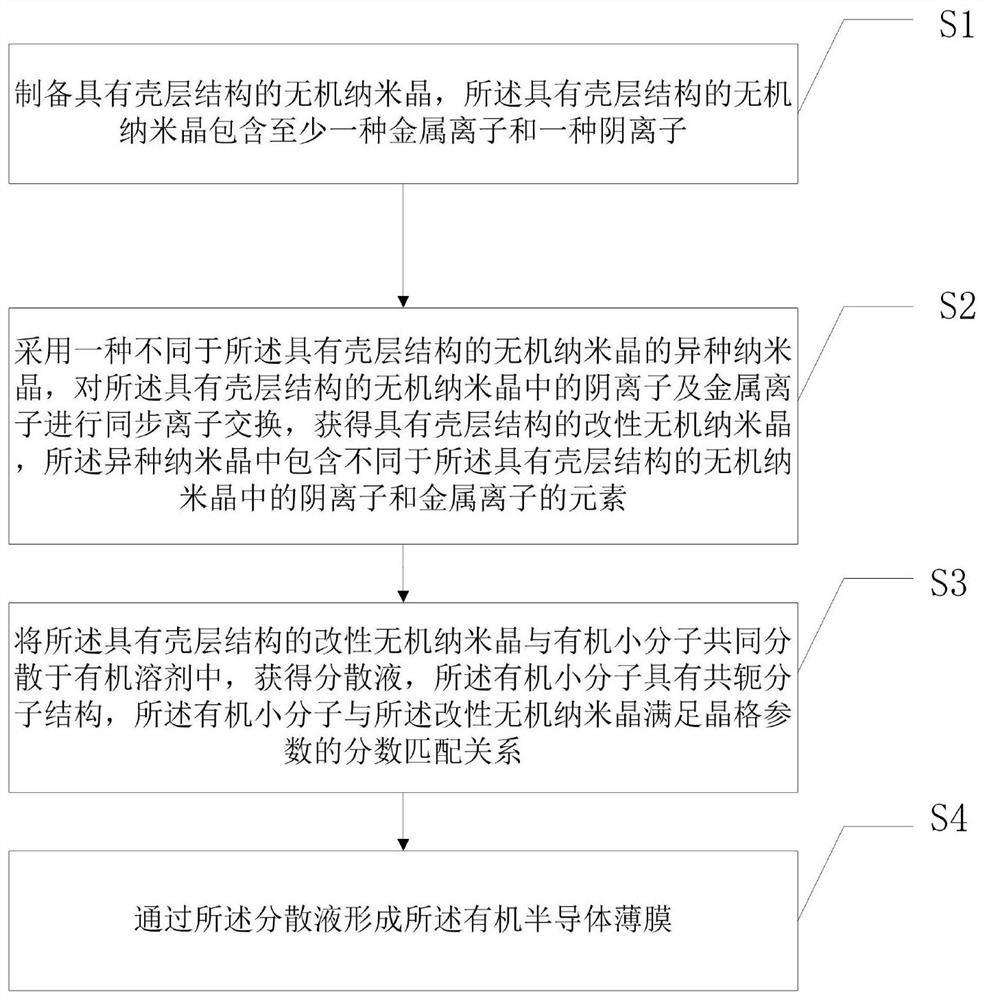

[0043] see figure 1 , the invention provides a kind of preparation method of organic semiconductor thin film, it comprises the following steps at least:

[0044] S1. Prepare an inorganic nanocrystal with a shell structure, the inorganic nanocrystal with a shell structure comprising at least one metal ion and one anion;

[0045] S2. Using a heterogeneous nanocrystal different from the inorganic nanocrystal with a shell structure, performing synchronous ion exchange on the anions and metal ions in the inorganic nanocrystal with a shell structure to obtain a shell structure Modified inorganic nanocrystals, the heterogeneous nanocrystals contain elements different from the anions and metal ions in the inorganic nanocrystals with a shell structure;

[0046] S3. Disperse the modified inorganic nanocrystals with a shell structure and organic small molecules in an organic solvent to obtain a dispersion liquid. The organic small molecules have a conjugated molecular structure, and the...

Embodiment 1

[0065] Please also refer to Figure 5 , using in situ mercaptosilane passivation method to prepare in situ mercapto nanocrystals (InMP-CsPbBr 3 ), that is, in the preparation of CsPbBr using the hot injection method 3 In the process of nanocrystallization, 3-mercaptopropyltrimethoxysilane (MPTMS) was added as a ligand in the precursor solution. Films were prepared on glass substrates by drop coating, and the XRD results of the nanocrystalline films obtained by 2θ scanning were as follows: Figure 5 shown, showing CsPbBr 3 There is lattice continuity between the cubic phase lattice of silicon oxide and the hexagonal phase lattice of silicon oxide, and the specific performance has the following characteristics: (1) (200) interplanar spacing d of the cubic phase 200 d with hexagon 011 Similar, corresponding to the 2θ diffraction peaks at ~30.6° and ~30.4° respectively; (2) Referring to the column height of the PDF card, the cubic phase CsPbBr 3 Compared with the (211) diffra...

Embodiment 2

[0067] see Figure 6 to Figure 10 , different from Example 1, the preparation method of the present invention can also adopt the method of ligand exchange to prepare the mercapto-silane-passivated mercapto-exchanged nanocrystals (ExMP-CsPbBr 3 ), the formed nanocrystalline powder XRD with a shell structure shows Image 6 shown. This method is used in the preparation of CsPbBr by hot injection 3 In the process of nanocrystals, MPTMS was not added to the precursor solution; the resulting CsPbBr 3 The heptane dispersion of nanocrystals was mixed with MPTMS at a certain volume ratio at room temperature and stirred for 12 hours to obtain ExMP-CsPbBr 3 Nanocrystalline. Compared to the control sample without ligand exchange, the cubic phase CsPbBr 3 The (200) diffraction peak shifts slightly to the small angle direction, and the crystallinity decreases to a certain extent, which is the result of the stress exerted by the silica shell on the perovskite cubic lattice. see Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com