Efficient corrosion inhibitor for resisting carbon dioxide corrosion and preparation method thereof

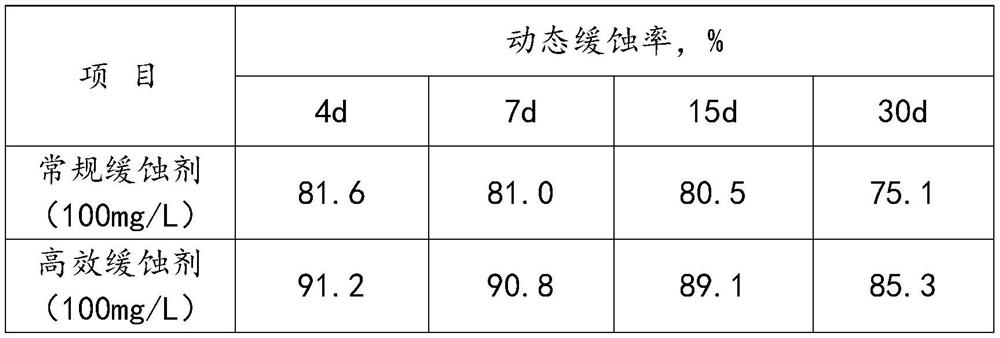

A carbon dioxide and corrosion inhibitor technology, which is applied in the field of high-efficiency corrosion inhibitors for anti-carbon dioxide corrosion and its preparation, can solve problems such as being easily absorbed by rock formations, unsatisfactory anti-corrosion effects, and short validity periods, and achieve good compatibility and improved corrosion resistance. Corrosion inhibition effect, the effect of corrosion inhibition effect enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

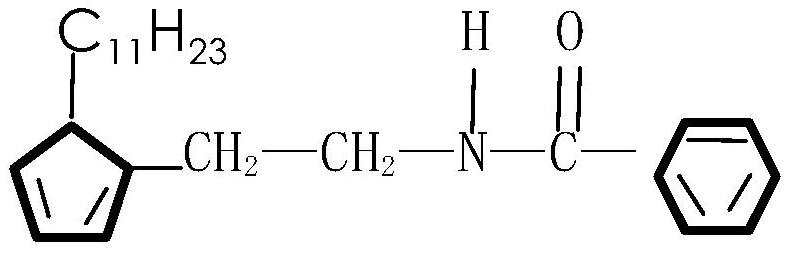

Image

Examples

Embodiment 1

[0028] A kind of preparation method of high-efficiency corrosion inhibitor for carbon dioxide corrosion resistance is:

[0029] Step 1: Prepare solid polyaspartic acid into a solution with a mass concentration of 0.1%. The specific method is: put 300mL tap water in a 500mL beaker, turn on the stirring device, and make the water surface form a vortex. g of solid polyaspartic acid powder was evenly added to the vortex, and the stirring was continued for 1.5 hours to form a uniform liquid.

[0030] Step 2: Prepare the solid oxygen scavenger N,N,N',N'-tetrasubstituted phenylenediamine into a solution with a mass concentration of 80mg / L. The specific method is: put 500mL of tap water in a 1000mL beaker and place it under a magnetic force On the stirrer, add 0.04g of solid oxygen scavenger evenly into the beaker at a speed of 400r / min, stir for 20min to completely dissolve and form a uniform liquid. Take out 100 g of the homogeneous liquid, add 70 g of liquid oxygen scavenger N-iso...

Embodiment 2

[0041]A kind of preparation method of high-efficiency corrosion inhibitor for carbon dioxide corrosion resistance is:

[0042] Step 1: Prepare solid polyaspartic acid into a solution with a mass concentration of 0.15%. The specific method is: put 300mL tap water into a 500mL beaker, turn on the stirring device, and make the water surface form a vortex. g solid polyaspartic acid powder was evenly added to the vortex, and continued to stir for 2 hours to form a uniform liquid.

[0043] Step 2: Prepare the solid oxygen scavenger N,N,N',N'-tetrasubstituted phenylenediamine into a solution with a mass concentration of 90mg / L. On the stirrer, add 0.045g of solid oxygen scavenger evenly into the beaker at a speed of 400r / min, stir for 20min to completely dissolve and form a uniform liquid. Take out 100 g of the homogeneous liquid, add 70 g of liquid oxygen scavenger N-isopropylhydroxylamine and mix uniformly to obtain an oxygen scavenger mixture.

[0044] Step 3: Add 100g of 0.15% ...

Embodiment 3

[0054] A kind of preparation method of high-efficiency corrosion inhibitor for carbon dioxide corrosion resistance is:

[0055] Step 1: Prepare solid polyaspartic acid into a solution with a mass concentration of 0.2%. The specific method is: put 300mL tap water in a 500mL beaker, turn on the stirring device, and make the water surface form a vortex. g solid polyaspartic acid powder was evenly added to the vortex, and continued to stir for 2 hours to form a uniform liquid.

[0056] Step 2: Prepare the solid oxygen scavenger N,N,N',N'-tetrasubstituted phenylenediamine into a solution with a mass concentration of 100mg / L. The specific method is: put 500mL tap water in a 1000mL beaker, place it On the stirrer, add 0.05g of solid oxygen scavenger evenly into the beaker at a speed of 400r / min, stir for 30min to completely dissolve and form a uniform liquid. Take out 100 g of the homogeneous liquid, add 70 g of liquid oxygen scavenger N-isopropylhydroxylamine and mix uniformly to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com