Antistatic fabric with static electricity eliminating function and preparation method thereof

An antistatic fabric and static elimination technology, applied in the direction of static electricity, dyeing method, electrical components, etc., can solve the problems of non-perfect elimination of static electricity and cost reduction, negligible antistatic effect, and limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

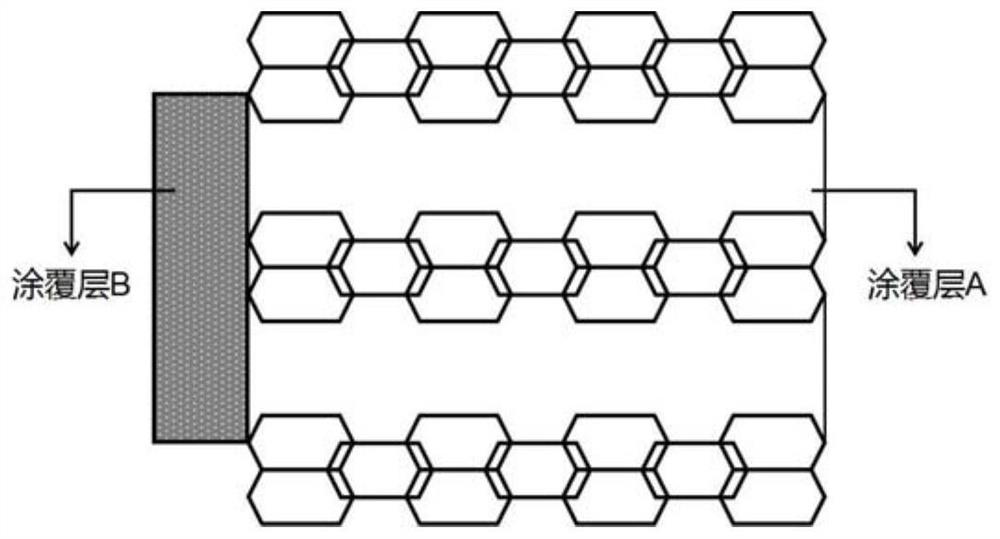

Method used

Image

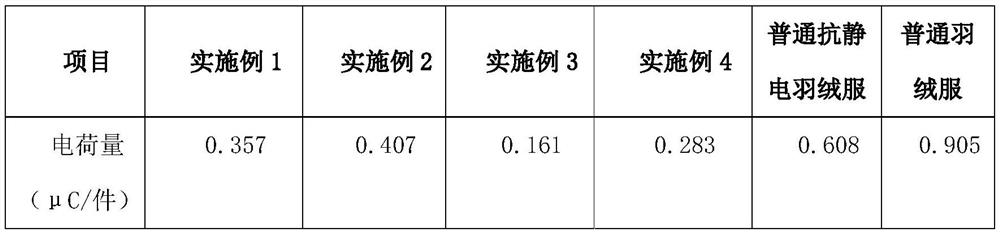

Examples

Embodiment 1

[0030] (1) Add modified carbon black and polyurethane polymer into a flask equipped with a stirrer, stir fully for 30-60min under the stirring of a magnetic stirrer, and then place the beaker in an ultrasonic cleaner for ultrasonic dispersion for 1-2h.

[0031] (2) Let the emulsion stand still for 24 hours, and take the solution above the emulsion as the polyurethane-coated carbon black solution when in use.

[0032] (3) After the polyurethane carbon black coating solution is dried, the micron-sized particles are obtained by a mechanical pulverization mechanism, and then the polyurethane carbon black nanoparticles are coated by chemical methods.

[0033] (4) After stirring 20-50% polycarbodiimide and 30-60% acetone to make them evenly mixed, then according to the proportion, polyurethane-coated carbon black nanoparticles are put into an organic solvent, fully stirred, so that The dispersion is uniform to prepare polyurethane-coated carbon black nano-solution.

[0034] (5) Add...

Embodiment 2

[0040] (1) According to the steps (1) to (4) of Example 1, a polyurethane-coated carbon black nanometer solution was prepared.

[0041](2) After mixing nickel sulfate, sodium phosphate, ammonium chloride, triethanolamine, sodium phosphate, sodium citrate dihydrate and carbon black powder, fully stir for 60 minutes to coat the carbon black powder with a nickel layer.

[0042] (3) Clean the electroless nickel-plated carbon black solution with deionized water, and then dry it in a vacuum oven to obtain nickel-plated carbon black particles.

[0043] (4) Stir 20-50% polycarbodiimide and 30-60% acetone to make them evenly mixed, then add nickel-plated carbon black particles into the solvent according to the proportion, stir well to make them evenly dispersed Prepare nickel-plated carbon black nanometer solution.

[0044] (5) Polyurethane-coated carbon black nano-solution and nickel-plated carbon black nano-solution are passed through screen printing mode, and according to required ...

Embodiment 3

[0046] (1) Add graphene and polyurethane polymers into a flask equipped with a stirrer, and fully stir for 30-60 minutes under the stirring of a magnetic stirrer, and then place the beaker in an ultrasonic cleaner for ultrasonic dispersion for 1-2 hours.

[0047] (2) The emulsion is left to stand for 24 hours, and the solution above the emulsion is taken as the polyurethane-coated graphene solution during use.

[0048] (3) After the polyurethane graphene coating solution is dried, a mechanical pulverization mechanism is used to obtain micron-sized particles, and then a chemical method is used to obtain polyurethane coated graphene nanoparticles.

[0049] (4) Stir 20-50% polycarbodiimide and 30-60% acetone to make them evenly mixed, then put polyurethane-coated graphene nanoparticles into an organic solvent according to the proportion, fully stir, so that The dispersion is uniform to prepare polyurethane-coated graphene nano solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com