Modified silk-screen printing electrode and application thereof

A screen-printed electrode and modified technology, which is applied in the field of electrochemical analysis and detection, can solve the problems of limited wide application, unsuitable basic use, bulky instrument, etc., and achieves the effect of improving arsenic detection signal, easy operation and high-sensitivity detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Printing of screen-printed electrodes

[0039] Mix commercial carbon slurry, carbon nanotubes and oxalic acid, stir at a constant speed for 24h, and rotate at a speed of 120r / min to obtain a modified carbon slurry; wherein, the inner diameter of the carbon nanotubes: 5-15nm, outer diameter: 30-80nm and length<10 μm, Its mass fraction is 0.4%, oxalic acid accounts for 1.0% (mass fraction), and the rest is commercial carbon pulp.

[0040] The mesh of the screen printing screen used is 220 mesh, the tension is 25N, the hardness of the scraper is 80°, the angle is 70°, the speed is 1cm / s, and the height between the screen and the printing plate is 3mm.

[0041] First, the silver-silver chloride layer is printed on the PET substrate. The silver-silver chloride layer is printed in three non-contact rectangular printing areas, the left end of which is flush, and the middle left end can be divided into two parallel groups. The rectangular printing area is connected in the ...

Embodiment 2

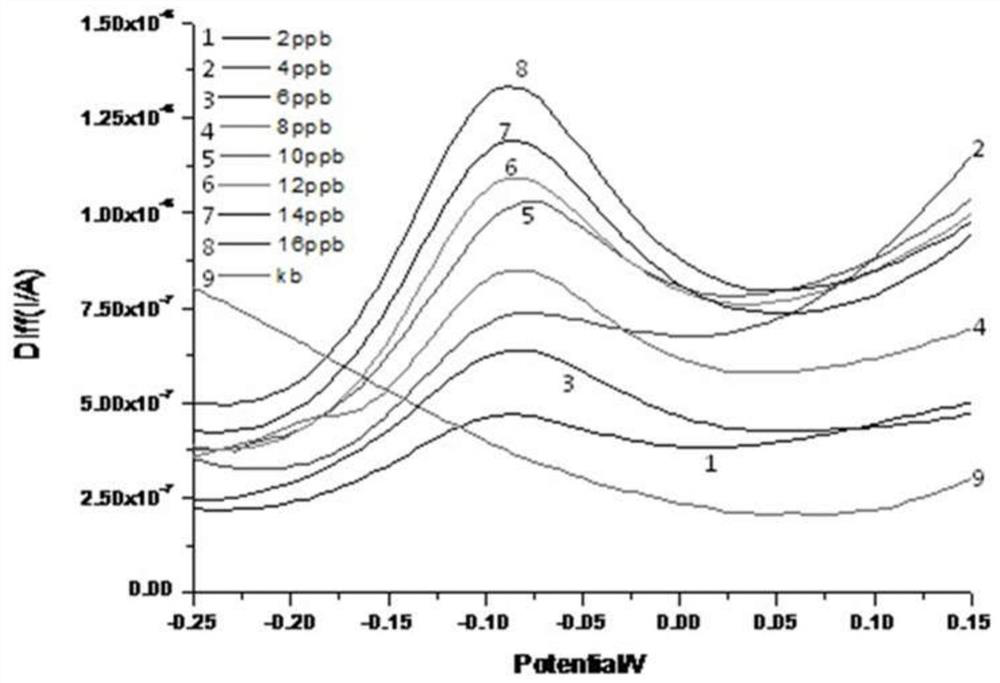

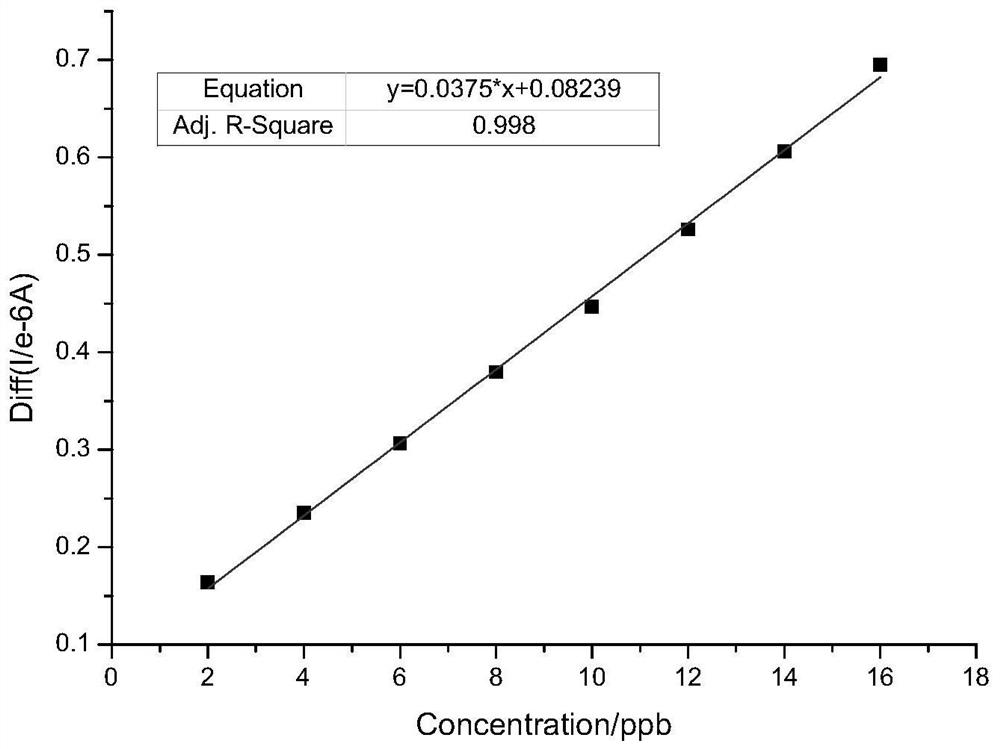

[0055] The difference from Example 1 is that polylactic acid with a mass fraction of 0.4% is added to the modified carbon slurry, and a series of test solutions with known arsenic concentrations are: 2.0, 4.0, 6.0, 8.0, 10, 12, 14 , 16ppb, and other preparation and detection processes are consistent with Example 1. The stripping voltammograms (such as Figure 4 ), record the stripping current intensity, specifically as shown in Table 2:

[0056] Table 2

[0057]

[0058]

[0059] The stripping current intensities of the same arsenic concentration in Example 1 and Example 2 are compared, as shown in Table 3:

[0060] table 3

[0061]

[0062] It can be seen that after adding 0.4% polylactic acid, the detection signal of arsenic was increased by about 50%.

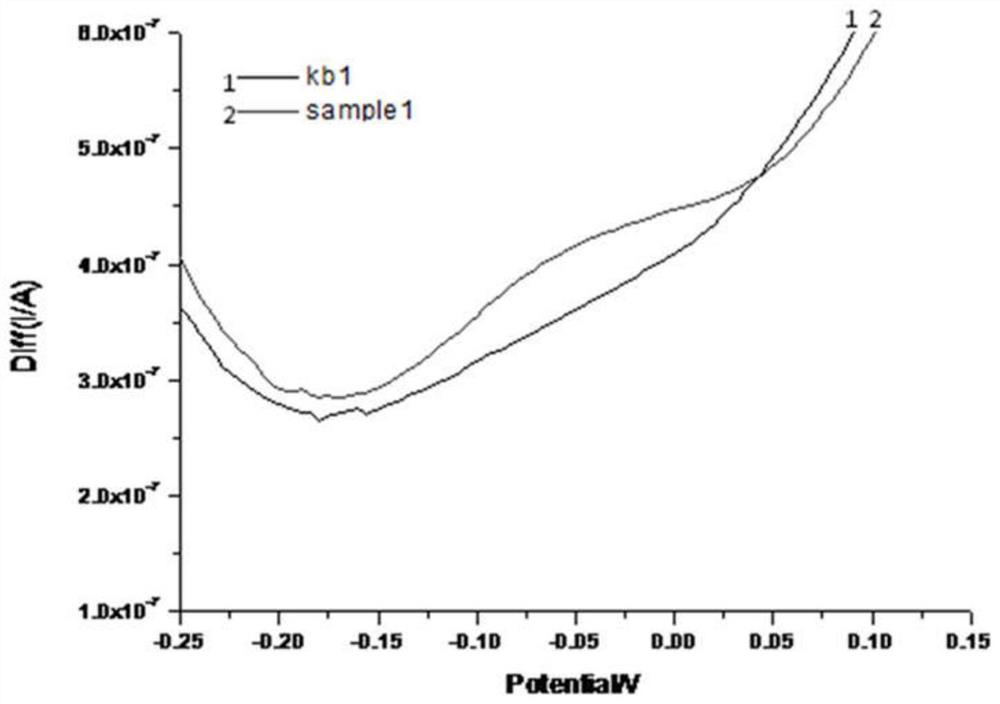

[0063] The stripping voltammogram under 4ppb concentration in embodiment 1 is compared with the stripping voltammogram under 4ppb concentration in embodiment 2 ( Figure 5 ), it can be seen that after the addit...

Embodiment 3

[0065] The difference from Example 1 is that the amount of oxalic acid added to the carbon slurry in the electrode preparation process is different, and the stripping current of the 4ppb trivalent arsenic standard solution was measured according to the experimental steps and detection parameters of Example 1.

[0066] The comparison of the stripping current intensity of arsenic detection by electrodes printed with different oxalic acid additions is shown in Table 4. The comparison shows that when the oxalic acid addition in the carbon slurry is 1.0-1.6%, the detection signal of the printed electrode is better, and the electrode detection signal is better when the oxalic acid content is increased. Ability enhancements don't help much.

[0067] Table 4

[0068]

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com