Electrode leading-out method and packaging method of tantalum electrolytic capacitor

A tantalum electrolytic capacitor and electrode lead-out technology, applied in the direction of electrolytic capacitors, capacitor electrodes, solid electrolytic capacitors, etc., can solve the problems of limiting product miniaturization, thinning, and low space utilization, and achieve increased reliability design margin, Improved space utilization and the effect of preventing short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] A specific embodiment of the present invention provides a method for leading out electrodes of a tantalum electrolytic capacitor, the method comprising the following steps S1-S4:

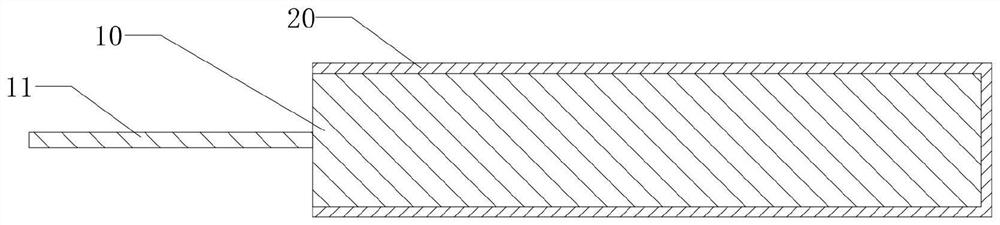

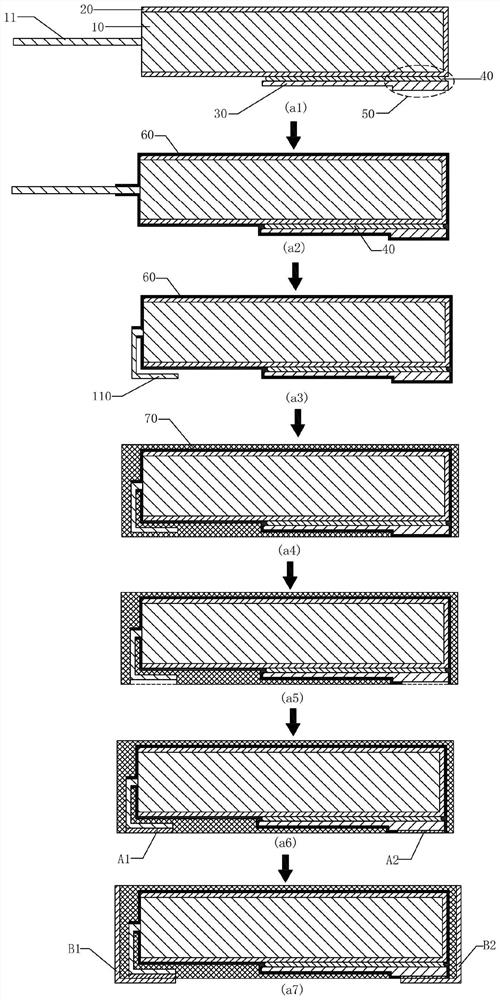

[0028] S1. Make an insulating protective layer outside the electrode body of the tantalum electrolytic capacitor. refer to figure 2 , Figure 4 or Figure 8 , the electrode body includes an anode tantalum core 10, a cathode layer 20 (the main body of the cathode layer is a conductive polymer layer, a graphite layer and a silver layer) and the terminal 11 (or 12, 13) of the tantalum core 10. It should be noted that, The dielectric layer (tantalum pentoxide) between the tantalum core 10 and the cathode layer 20 is not shown in the figure, that is to say, there is a dielectric layer between the tantalum core 10 and the cathode layer 20 shown in the drawings, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com