Liquid sulfur positive electrode and semi-liquid lithium-sulfur battery

A liquid sulfur and positive electrode technology, which is applied in the direction of lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of limited improvement in battery performance, low utilization of active materials, and large volume changes, and achieve good cycle stability and Power characteristics, solution to positive electrode sulfur insulation and volume expansion, and good ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Prepare 1.2mol / L Li in a mixed solvent of 1,3-dioxolane (DOL) and N,N-dimethylacetamide (DMAC) at a volume ratio of 0.5:1 2 S 6 Solution (that is, the sulfur concentration is 7.2mol / L), further according to the volume ratio of 1,1,2,2-tetrafluoroethyl-2,2,3,3-tetrafluoropropyl ether (TTE) and DMAC is 1.5:1 with TTE added as a supporting solvent. Finally add NiCl with a mass fraction of 0.5% 2 and 2% LiNO 3 , and get the desired sulfur-containing solution after mixing evenly.

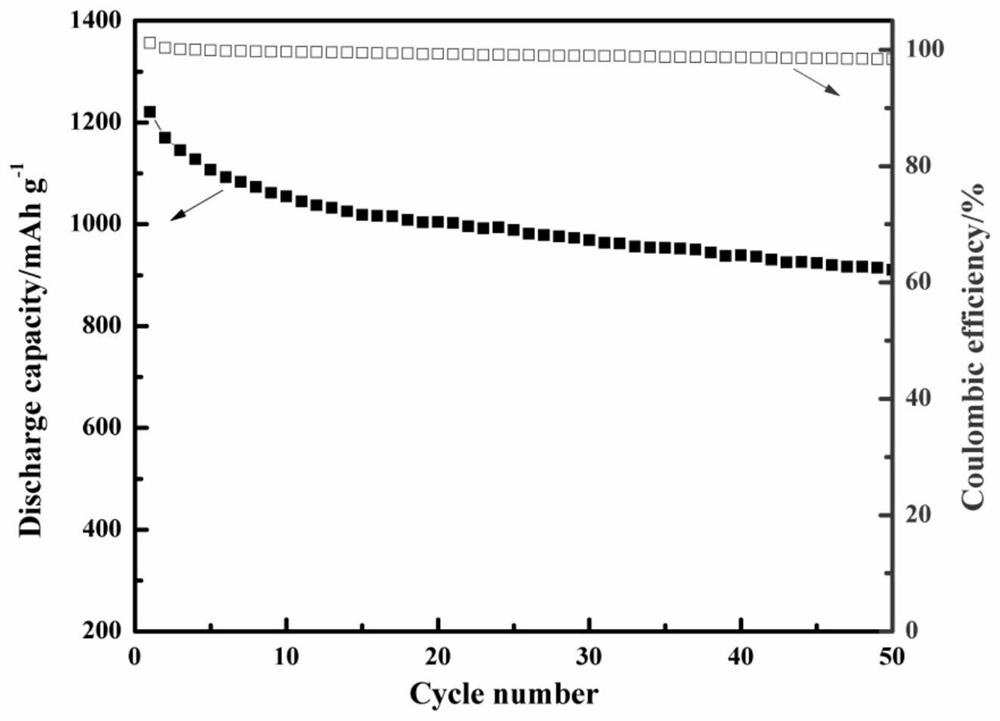

[0049] The above-mentioned sulfur-containing solution is dropped on the surface of carbon fiber cloth, and the separator and lithium metal are stacked to form a semi-liquid lithium-sulfur battery, such as figure 1 shown.

Embodiment 2

[0051] Prepare 1.0mol / L Li 2 S 8 solution (that is, the sulfur concentration is 8mol / L), and further press the volume ratio of 1,1,2,2-tetrafluoroethyl-2,2,2-trifluoroethyl ether (TFTFE) and DMSO to be 1:1 TFTFE was added as a supporting solvent. Finally add NH with a mass fraction of 10% 4 FSI, mixed evenly to obtain the desired sulfur-containing solution.

[0052] The above-mentioned sulfur-containing solution is dropped on the surface of carbon paper, and then laminated with separator and lithium metal to form a semi-liquid lithium-sulfur battery.

Embodiment 3

[0054] Prepare 1.5mol / L Li in dimethyl sulfoxide (DMSO) 2 S 6 solution (that is, the sulfur concentration is 9mol / L), further add TFEE according to the volume ratio of 1,2-bis(1,1,2,2-tetrafluoroethoxy)ethane (TFEE) and DMSO as 3:1 as a supporting solvent. Finally add 0.2% CoCl 2 and 0.2% LiNO 3 , and get the desired sulfur-containing solution after mixing evenly.

[0055] The above-mentioned sulfur-containing solution is dropped on the surface of the nickel mesh, and the semi-liquid lithium-sulfur battery is assembled by stacking with the diaphragm and lithium metal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com