Composite proton exchange membrane based on acetate fiber porous support body and preparation method thereof

A technology of proton exchange membrane and cellulose acetate, which is applied in the direction of fuel cells, electrochemical generators, electrical components, etc., can solve the problems that cannot be completely solved in the preparation of proton exchange membranes, such as operational performance, dimensional stability, alcohol resistance and mechanical properties. , Affect the actual use of polymer membranes with high sulfonation degree, etc., to achieve the effect of improving mechanical strength and aging resistance, compactness and high uniformity, and high peeling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

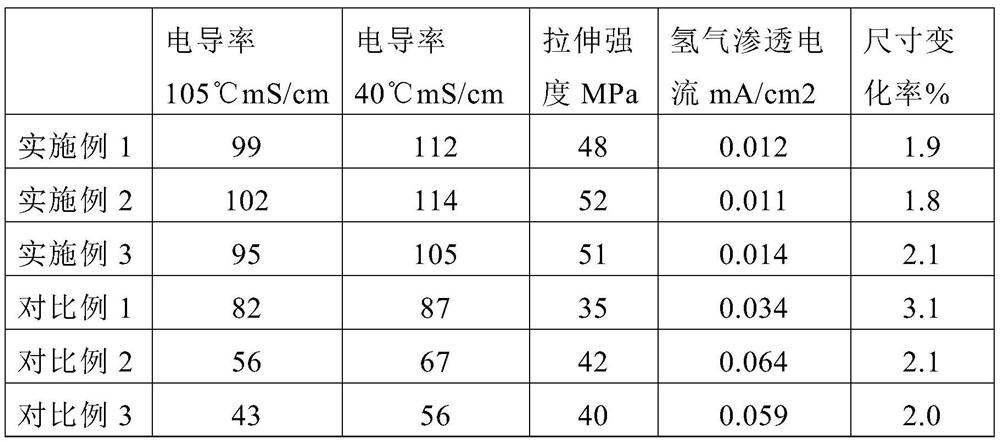

Examples

Embodiment 1

[0033] (1) Weigh 10 g of sulfonated polyetheretherketone and add it to a mixed solvent of 100 g of N-methylpyrrolidone, 50 g of isopropanol and 40 g of deionized water, and stir at room temperature for 12 hours to obtain a transparent polymer solution with a concentration of 5 wt %;

[0034] (2) Weigh 0.25g of phosphotungstic acid and add it to the polymer transparent solution in (1), stir at room temperature for 1 hour, and leave to defoam to obtain casting solution 3;

[0035] (3) Take by weighing 1g dicumyl peroxide and 0.1g nano silicon dioxide and join in the mixed solvent of 666g deionized water and 333g ethanol, ultrasonically disperse evenly, set aside;

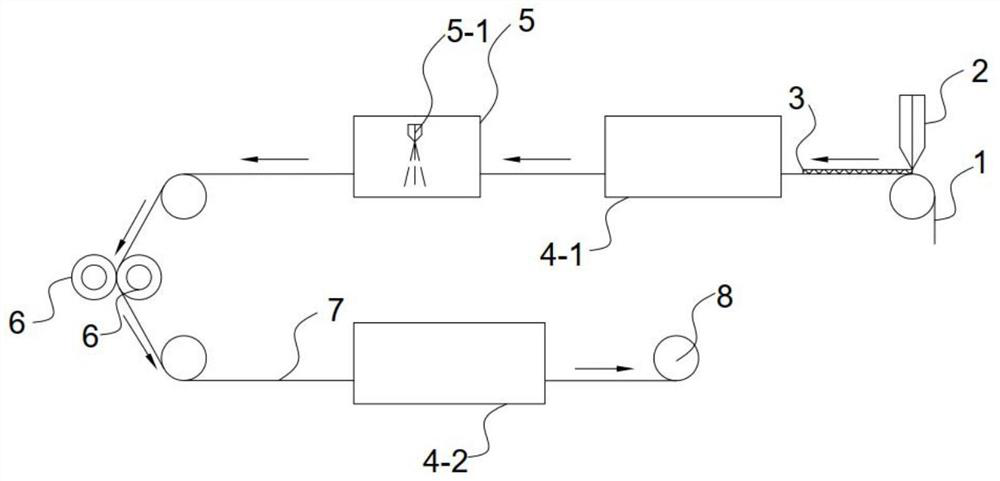

[0036](4) With the coating process of coating speed 1m / min, coating thickness 20 μ m, the casting solution 3 in (2) is evenly coated on the porous acetate support body 1 with the coating die head 2, at 60 ℃ The drying oven-4-1 is dried, then in the spraying chamber 5 with the spraying process of spraying flow rate 5mL...

Embodiment 2

[0038] (1) Weigh 20g of sulfonated polyethersulfone and add it to a mixed solvent of 59g N,N-dimethylformamide, 30g isopropanol and 24g deionized water, stir at room temperature for 12h, and obtain a transparent polymer with a concentration of 15wt%. solution;

[0039] (2) Weighing 3g of phosphomolybdic acid and adding it to the polymer transparent solution in (1), stirring at room temperature for 1h, and standing for defoaming to obtain casting solution 3;

[0040] (3) Take by weighing 3g benzoyl peroxide and 3g nanometer zinc oxide and join in the mixed solvent of 333g deionized water and 333g ethanol, ultrasonic dispersion is even, for subsequent use;

[0041] (4) Coating process with coating speed 5m / min, coating thickness 50μm uses coating die head 2 to uniformly coat casting liquid 3 in (2) on acetate porous support body 1, at 100 ℃ The drying oven-4-1 is dried, then in the spraying chamber 5 with the spraying process of spraying flow rate 10mL / min, spraying nozzle 5-1 ...

Embodiment 3

[0043] (1) Weigh 20 g of sulfonated polyphenylsulfone and add it to a mixed solvent of 95 g of dimethyl sulfoxide, 47 g of isopropanol and 38 g of deionized water, and stir at room temperature for 12 hours to obtain a polymer transparent solution with a concentration of 10 wt %;

[0044] (2) Weigh 2g of silicotungstic acid and add it to the polymer transparent solution in (1), stir at room temperature for 1 hour, and after standing for defoaming, the casting solution 3 is obtained;

[0045] (3) Take by weighing 1g benzoyl peroxide and 0.5g nano silicon dioxide and join in the mixed solvent of 165g deionized water and 133g ethanol, ultrasonically disperse evenly, set aside;

[0046] (4) With a coating speed of 3m / min and a coating thickness of 30 μm, the casting solution 3 in (2) is uniformly coated on the cellulose acetate porous support 1 with a coating die head 2 at 80° C. The oven one 4-1 is dried, then in the spraying chamber 5 with the spraying process of spraying flow ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com