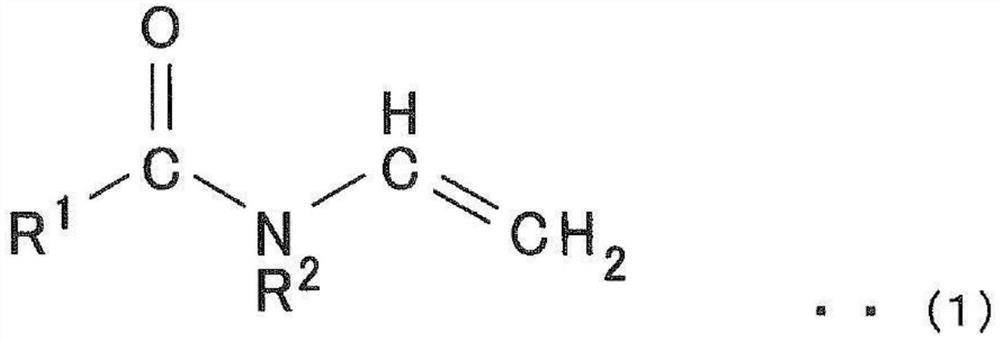

Composition for aqueous coating liquid containing n-vinylcarboxylic acid amide polymer

A technology of vinyl carboxylic acid amide and composition, applied in the direction of coating, device for coating liquid on the surface, latex paint, etc., can solve the problems of low concentration of thickening and dispersing agent, no disclosure and implied drying, etc. The effect of improving hydrophilicity and dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0106] Hereinafter, although an Example demonstrates this invention, this invention is not interpreted in any way limited to them.

manufacture example

[0108] Polymerization of N-vinylacetamide

[0109] A nitrogen vent tube, a stirrer, a solvent dripping device, and a thermometer were installed in four detachable flasks with a capacity of 1 liter. 550 g of ion-exchanged water was added to the detachable flasks, and N-vinylacetamide (Showa Denko Co., Ltd.) 50 g. In this state, nitrogen replacement in the solution is carried out while stirring and heating, and the polymerization initiation temperature is raised to 51°C, and the initiator 2,2'-azobis[N-(carboxyethyl)-2-methylpropane Amidine] tetrahydrate (hereinafter, VA-057) 0.04 g (total monomer ratio 0.08% by mass) was charged in a state dissolved in 10 g of ion-exchanged water degassed with nitrogen. In this state, the polymerization reaction was carried out for 4 hours, and then the internal temperature was raised to 80°C and kept for 1 hour, and then a sample was taken, and the residual monomer was measured by the HPLC method, and the reaction was defined as the time wh...

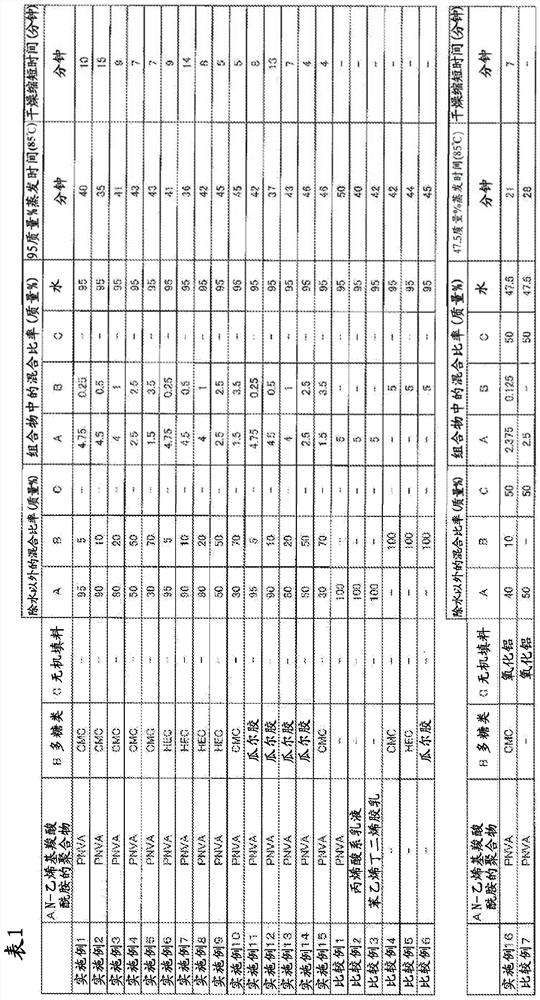

Embodiment 1~16

[0137] The polymer aqueous solution of 5% by mass of N-vinylacetamide obtained in the production example, and the 5% by mass aqueous solution of the polysaccharides shown in Table 1 were mixed at 25°C according to the mixing ratio in Table 1. Stirring and homogenization were performed in the same container to prepare a composition for an aqueous coating liquid. In addition, in Example 16, alumina was mixed in the ratio of Table 1 after homogenization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com