Electromagnetic field coupling high aspect ratio silicon substrate etching method

A high aspect ratio, electromagnetic field technology, applied in the manufacture of circuits, electrical components, semiconductor/solid state devices, etc., can solve the problems of uneven surface quality of formed structures, lack of electromagnetic field coupling interaction, etc., to avoid lattice defects, avoid Effects of mechanical stress and porosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] Such as Figure 1-4 As shown, the electromagnetic field coupled high aspect ratio etching method for silicon substrates includes the following steps:

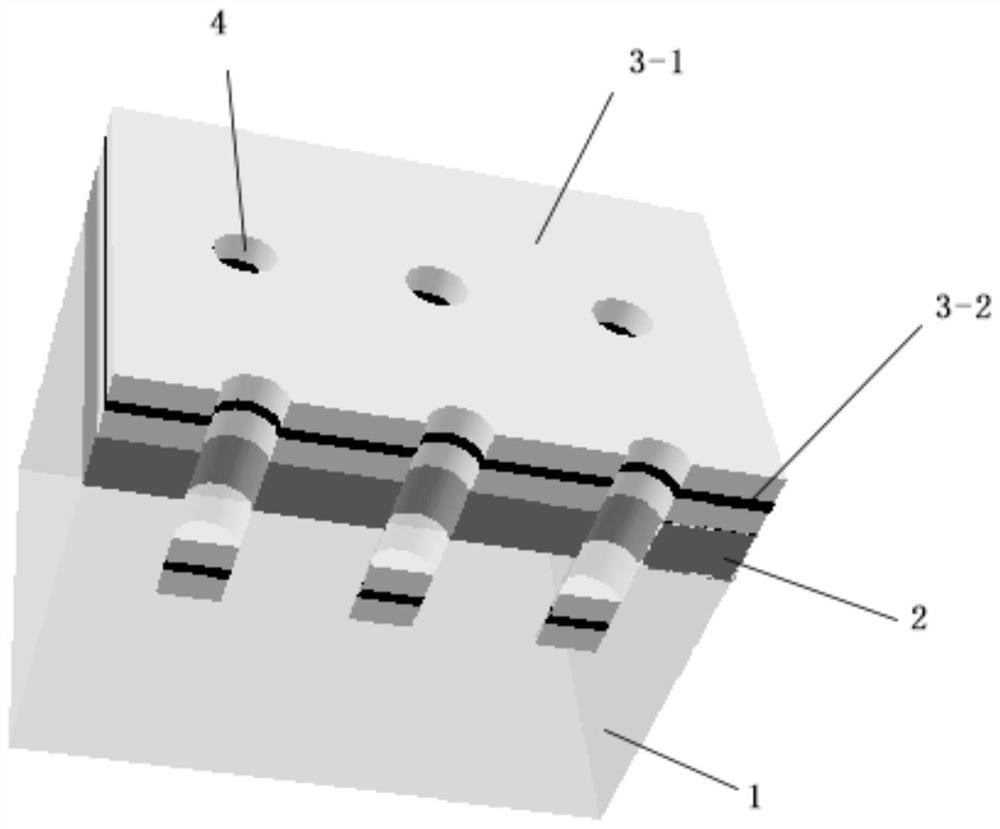

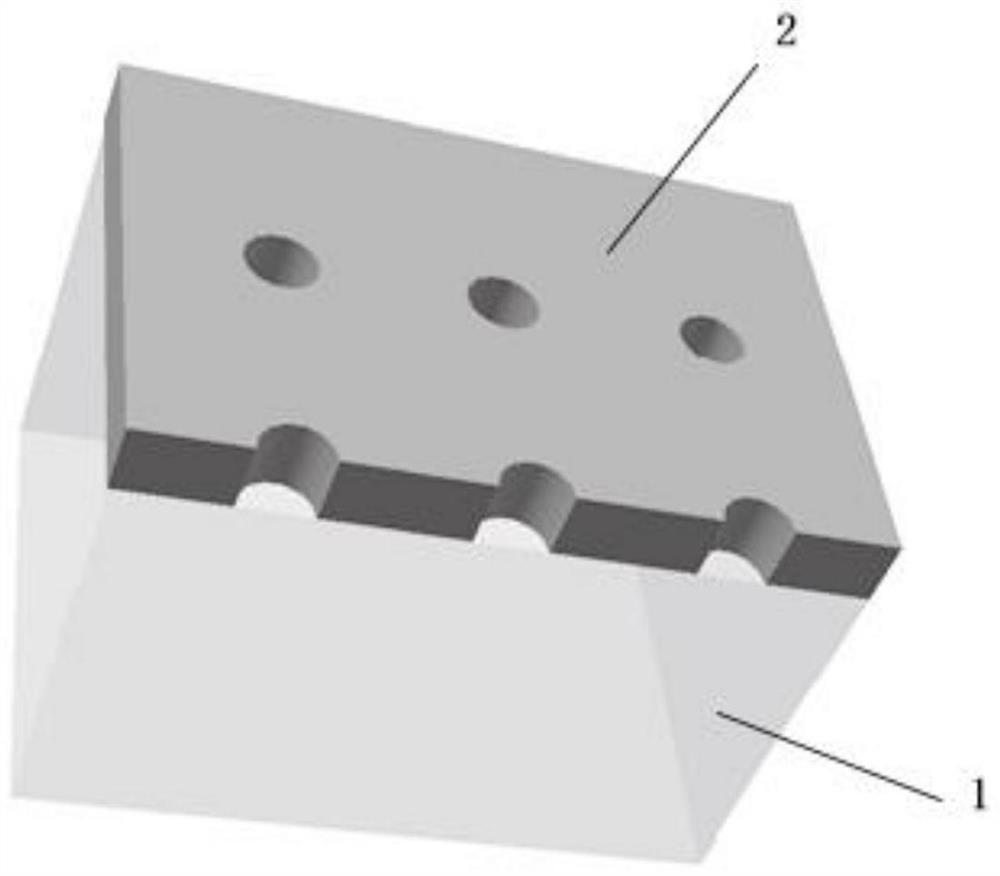

[0027] S1. A photoresist template 2 is set on the silicon base 1 as a mask for the silicon base 1, and a catalyst layer 3 is placed on the photoresist template 2. The catalyst layer is composed of a noble metal catalyst layer 3-1 and a magnetic layer 3-2. , the noble metal catalyst layer 3-1 is located on the upper and lower sides of the magnetic layer 3-2.

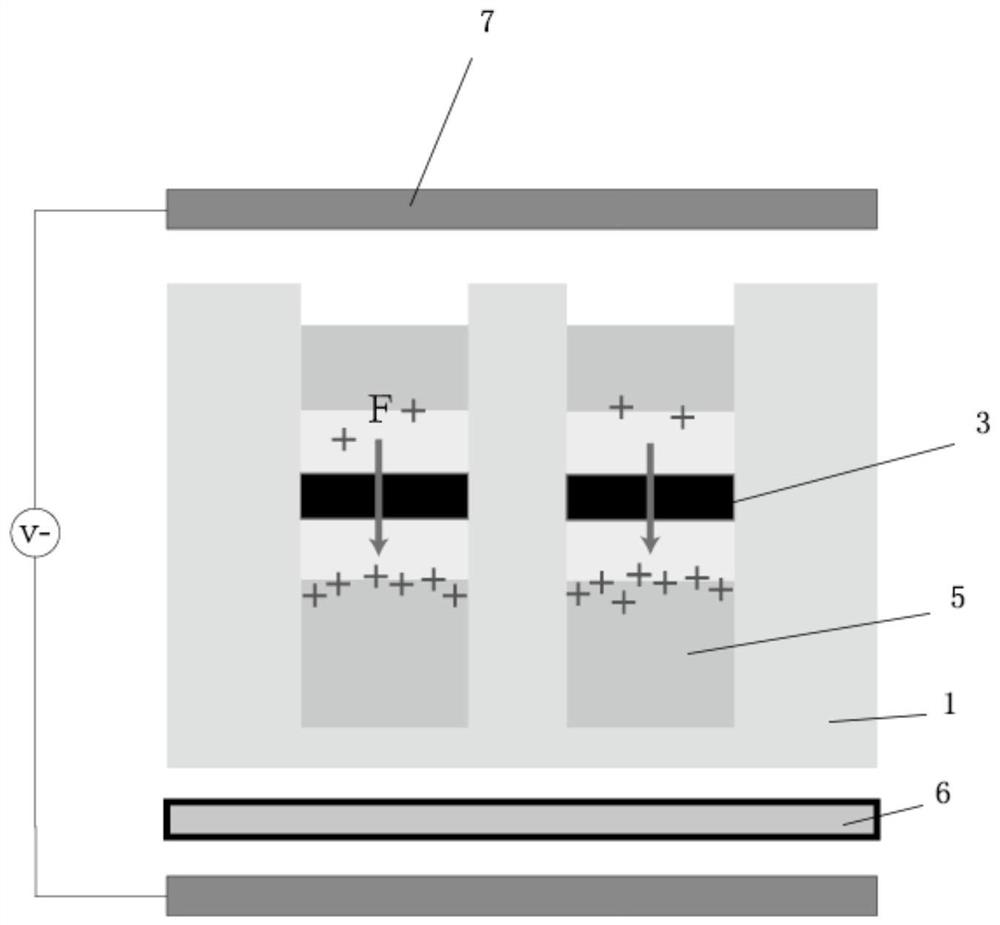

[0028] S2. Place the electromagnet 6 under the silicon base 1, the electromagnet 6 and the magnetic layer 3-2 are located on opposite sides of the silicon base 1;

[0029] S3. Add electrode plates 7 on the upper and lower sides of the silicon base 1, and connect a DC power supply.

[0030] The noble metal catalyst layer 3-1 is Au, the mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com