Method for preparing sulfide semiconductor/metal nanoparticles based on sulfur vacancy defect and application of sulfide semiconductor/metal nanoparticles

A technology of metal nanoparticles and vacancy defects, applied in the field of photocatalysis, can solve problems such as cumbersome operation, semiconductor damage, and affecting photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better illustrate the present invention and facilitate understanding of the technical solution of the present invention, the present invention will be further described in detail below.

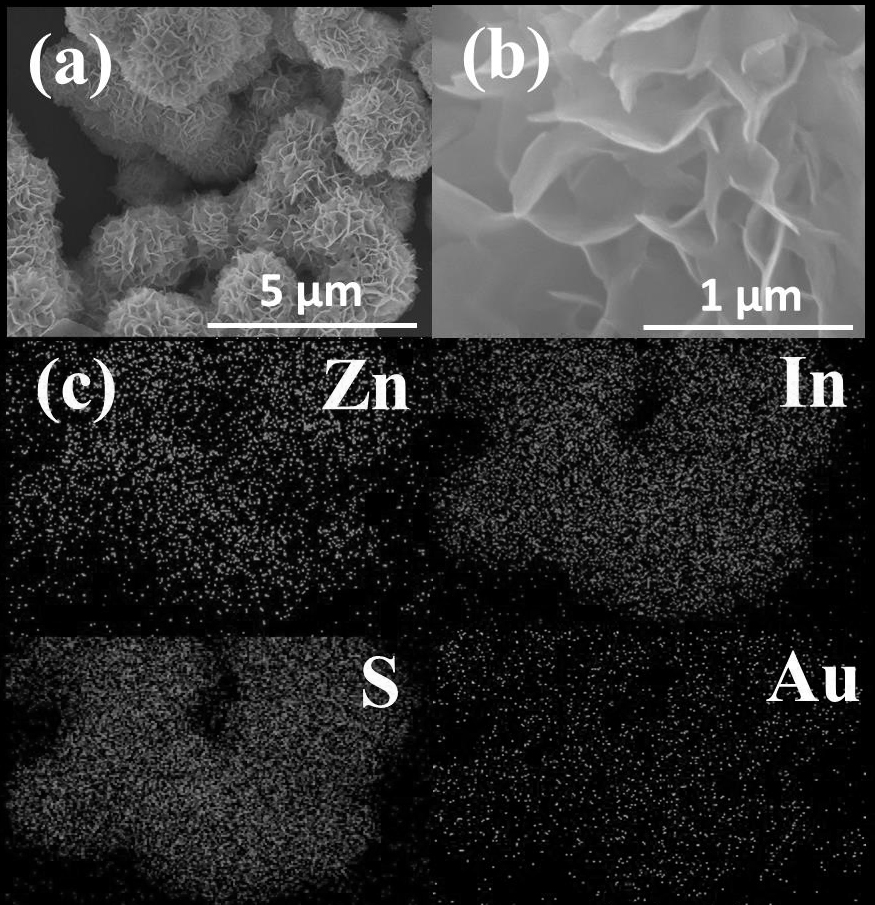

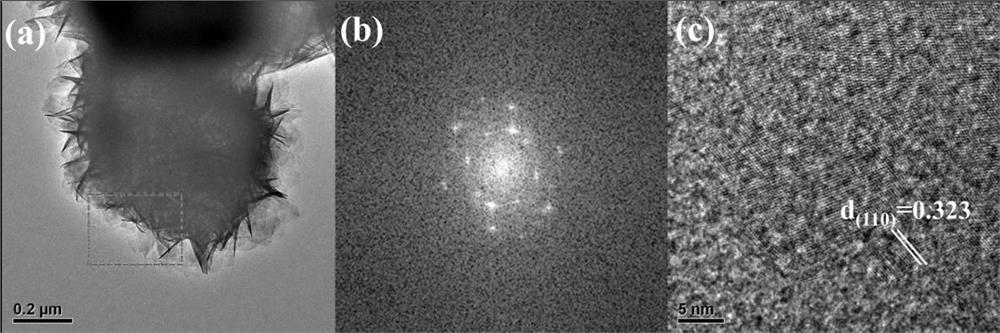

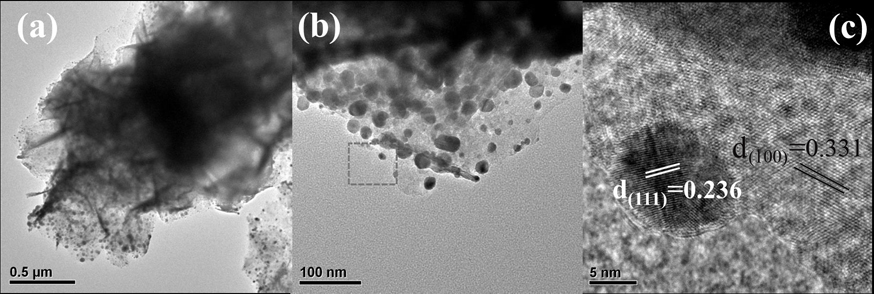

[0027] The sulfide semiconductor ZnIn with sulfur vacancy defects 2 S 4 Prepared by the following method: with ZnCl 2 Zinc source, InCl 3 ZnIn is prepared by solvothermal method as the indium source, thioacetamide (TAA) as the sulfur source and the mixed solution of ethylene glycol and water as the reaction medium 2 S 4 Nanocatalyst: ZnCl 2 ∙4H 2 O, InCl 3 ∙4H 2 O and TAA were dissolved in the mixed solution of ethylene glycol and water, the ZnCl 2 ∙4H 2 O, InCl 3 ∙4H 2The molar ratio of O and TAA was 1:2:4, and the stirring was continued for 60 min. Then, it was transferred to a reactor and kept at 150 °C for 12 h. Wait for the reaction kettle to cool down to room temperature naturally, centrifuge and wash the obtained precipitate, and dry it in a vacuum oven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com