A kind of green polymer compound sludge curing agent and its application

A polymer compound and curing agent technology, applied in the direction of fixed/solidified sludge treatment, sludge treatment, chemical instruments and methods, etc., to achieve the effects of high efficiency, short curing time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

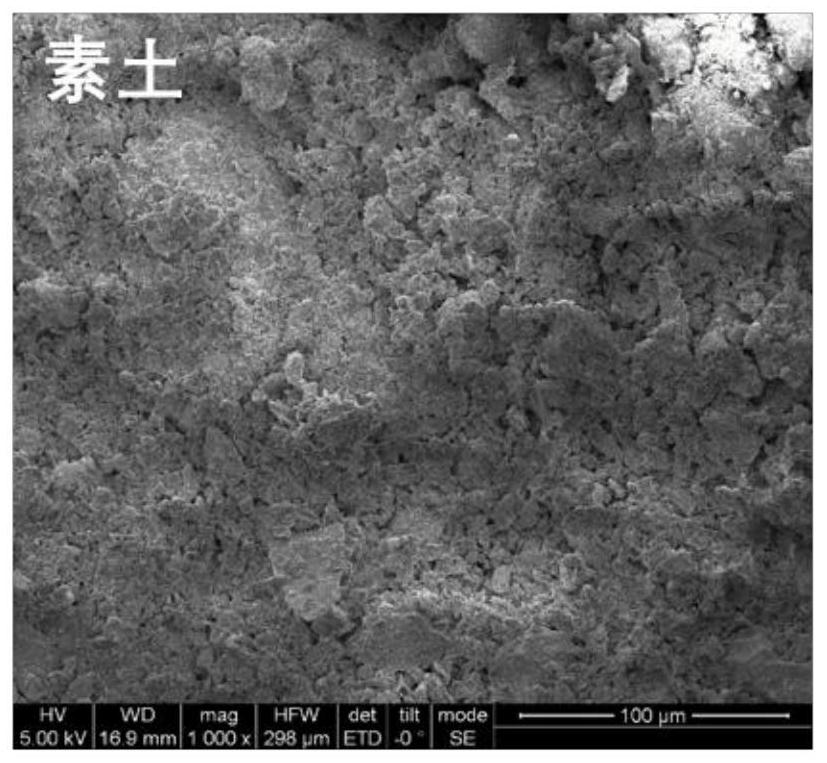

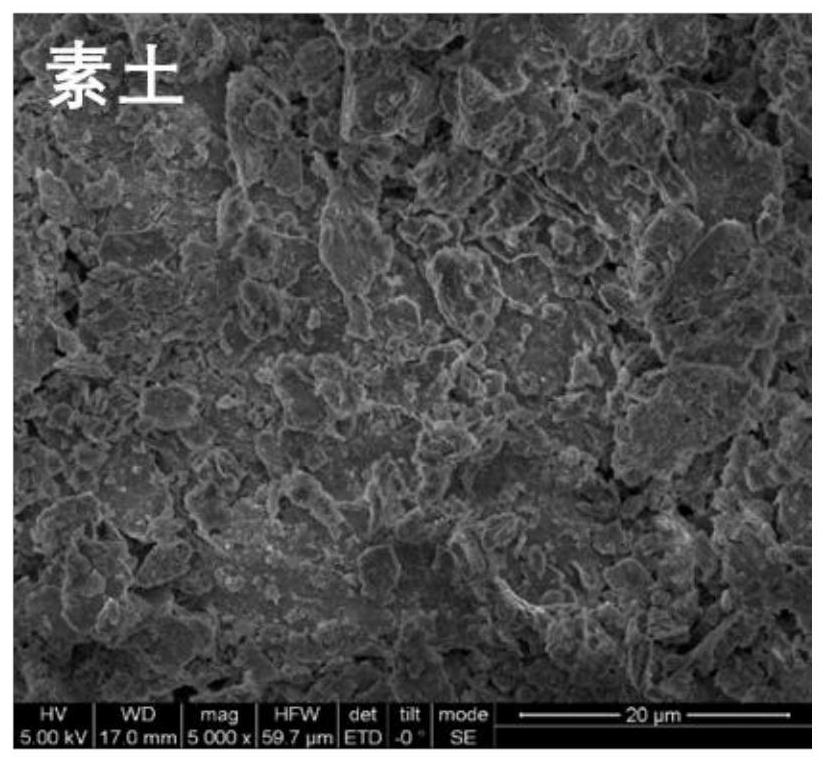

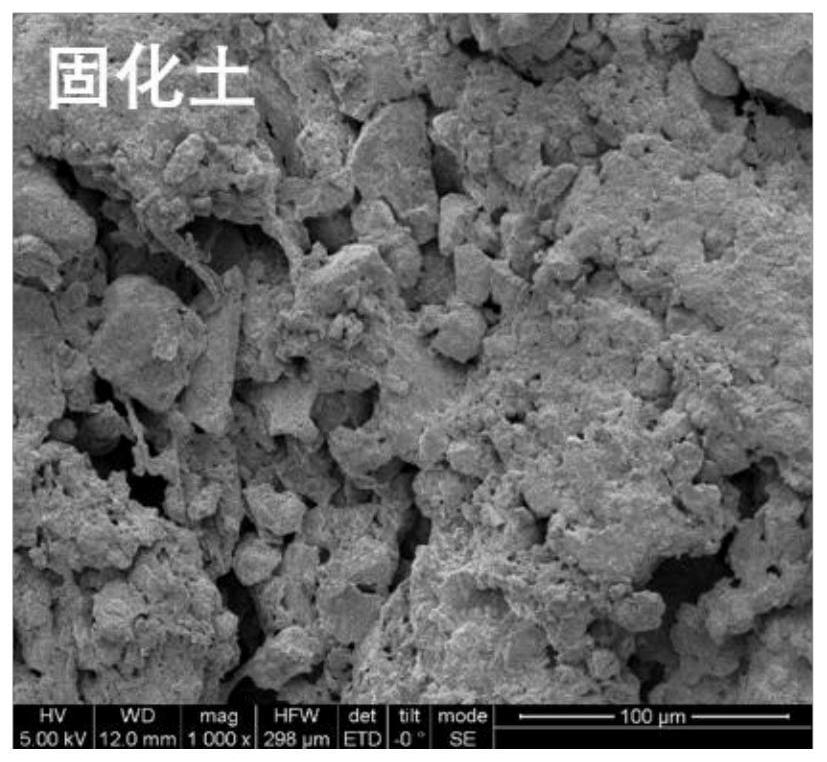

Image

Examples

Embodiment 1

[0021] The green polymer compound sludge curing agent described in this embodiment is made of the following components in mass percentage: calcium oxide 9%, tricalcium silicate 6%, tricalcium aluminate 15%, halloysite nanofiber 16%, Diatomaceous earth 4%, calcium chloride 3%, calcified polyacid 6%, organosilicon 21%, sodium carboxymethyl cellulose 2%, sodium polyphosphate 18%.

Embodiment 2

[0023] The green polymer compound sludge curing agent described in this embodiment is made of the following components in mass percentage: calcium oxide 12%, tricalcium silicate 6%, tricalcium aluminate 12%, halloysite nanofiber 16% , Diatomaceous Earth 4%, Calcium Chloride 3%, Calcified Polyacid 6%, Silicone 21%, Sodium Carboxymethyl Cellulose 2%, Sodium Polyphosphate 18%.

Embodiment 3

[0025] The green polymer compound sludge solidifying agent described in this embodiment is made of the following components in mass percentage: calcium oxide 12%, tricalcium silicate 6%, tricalcium aluminate 12%, halloysite nanofiber 14% , 6% diatomaceous earth, 3% calcium chloride, 6% calcified polyacid, 21% organic silicon, 2% sodium carboxymethyl cellulose, 18% sodium polyphosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com