Multifunctional composite burner power generation device

A power generation device and burner technology, which is applied in steam generation devices, machines/engines, steam generation, etc., to achieve the effect of simplifying the reheating and vaporization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

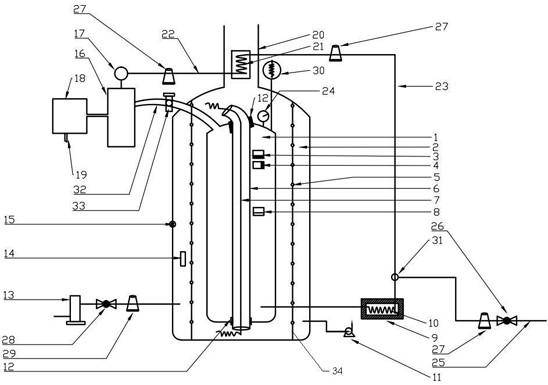

[0075] Push on the switch, start the central control (DCS) system, set the operating parameters, and when the control system is running normally, execute the instruction to open the electromagnetic water valve 26 and the water pump 27 of the water inlet pipe 25, add the boiler oxygen scavenger to the reverse osmosis water, and the pump Into the water storage tank 1. Then start blower 11, make the air slowly flow in combustion chamber 2. When the water level control sensor 8 shows that the water level reaches 50% of the water tank 1, proceed to the next step.

[0076] Turn on the power supply of the electric heating rod 7 for heating, turn on the gas valve 28 and the gas pump 29, send the gas into the combustion chamber 2 through the gas flow meter 13, and at the same time turn on the ignition gun 14, and observe the combustion state and flame color of the flame through the flame sight glass 15 , from which the flame temperature at that time can be judged. Preliminary judgmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com