Preparation method of cannabis sativa corn steep liquor

A technology of corn steep liquor and corn steep liquor powder, which is applied in the direction of dairy products, milk preservation, milk substitutes, etc. It can solve the problems that starch is not easy to completely gelatinize, precipitate, and corn steep liquor is easy to deteriorate, so as to achieve high protein content, good taste, Fragrant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

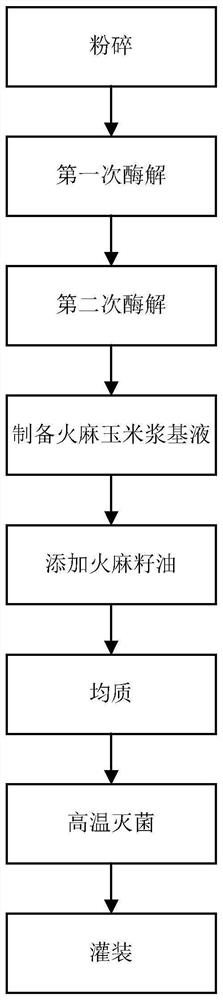

Image

Examples

Embodiment 1

[0030] A preparation method of hemp corn syrup, comprising the steps of:

[0031] (1) crush corn, add hemp seed powder, add water and stir and mix;

[0032] Pour the impurity-removed corn into the soaking tank, add water at 30-35°C until the corn is completely submerged and soak for 24-48 hours; crush the soaked corn to form corn flour; screen the hemp seeds to remove impurities. Hemp seeds are mechanically pressed at room temperature to separate oil and hemp seed meal; supercritical extraction is used to remove excess oil from hemp seed meal to obtain dry meal; weigh 90-100 parts of hemp seed dry meal and corn flour respectively by weight Carry out extrusion and puffing after mixing, add 0.01 part of nano-zinc oxide, stir again until the raw materials are evenly mixed, put the evenly stirred raw materials into a mill for milling, add water and stir evenly;

[0033] The advantage of using pre-extrusion and puffing treatment is that it can be more conducive to the precipitatio...

Embodiment 2

[0061] A preparation method of hemp corn syrup, comprising the steps of:

[0062] (1) crush corn, add hemp seed powder, add water and stir and mix;

[0063] Pour the impurity-removed corn into the soaking tank, add water at 30-35°C until the corn is completely submerged and soak for 50 hours; crush the soaked corn to form corn flour; screen the hemp seeds to remove impurities, and use the hemp seeds Carry out normal temperature mechanical pressing to separate oil and hemp seed meal; adopt supercritical extraction to remove excess oil to obtain dry meal; weigh 90-100kg hemp seed dry meal and corn flour respectively by weight; after mixing Carry out extrusion and puffing treatment, add 0.01-0.015kg of nano-zinc oxide, stir again until the raw materials are evenly mixed, put the evenly stirred raw materials into a mill for milling, add water and stir evenly;

[0064] (2) Add protease and high-temperature amylase to the mixture for the first enzymolysis; add alkaline protease in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com