A kind of preparation technology of high-efficiency flue gas mercury removal adsorbent

A preparation process and technology of adsorbent, applied in the field of adsorbent preparation, can solve problems such as affecting the activity, and achieve the effect of overcoming the agglomeration of active centers and avoiding the agglomeration of nano-carrier particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Put nano-sized ceria into a low-temperature plasma reactor, fix ceria so that it is in the discharge area; flow hydrogen into the reactor at a flow rate of 20mL / min at room temperature, and stop after 2 hours of discharge at a certain power ; Fully mix cerium oxide with a certain amount of nitrate solution, soak at room temperature for 12 hours, and then dry at 100°C until the water evaporates completely to obtain an adsorbent precursor with a loading capacity of 2.5%; put the precursor into In the plasma reactor, nitrogen gas was introduced at a flow rate of 20 mL / min, and the discharge power was 20 W for 2 h to obtain a nanoscale ceria adsorbent loaded with active centers. The obtained adsorbent was subjected to simulated flue gas demercuration experiment. Table 1 shows the effect of different discharge powers on the mercury removal efficiency of the adsorbent when dealing with oxygen defects.

[0019] Table 1 Effect of different nitrates on the mercury removal effic...

Embodiment 2

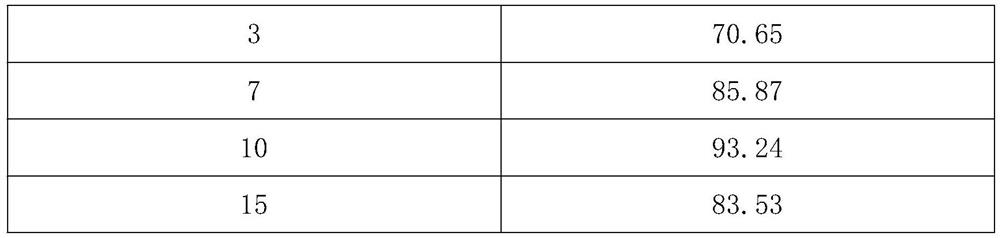

[0022] Put nano-sized ceria into a low-temperature plasma reactor, fix ceria so that it is in the discharge area; flow hydrogen into the reactor at a flow rate of 20mL / min at room temperature, and stop after 2 hours of discharge at a certain power ; Fully mix cerium oxide with a certain amount of cobalt nitrate solution, impregnate at room temperature for 12 hours, and then dry at 100°C until the water evaporates completely to obtain an adsorbent precursor with a loading capacity of 2.5%; put the precursor into In the plasma reactor, nitrogen gas was introduced at a flow rate of 20 mL / min, and the discharge power was 20 W for 2 h to obtain a nano-scale ceria adsorbent loaded with active center cobalt. The obtained adsorbent was subjected to simulated flue gas demercuration experiment. The effects of different discharge powers on the mercury removal efficiency of adsorbents when dealing with oxygen defects are shown in Table 2.

[0023] Table 2 Effects of different discharge p...

Embodiment 3

[0027] Put nano-scale ceria into a low-temperature plasma reactor, fix ceria so that it is in the discharge area; pass hydrogen gas into the reactor at a certain flow rate at room temperature, and stop after 2 hours of discharge at 10W power; Fully mix cerium oxide with a certain amount of cobalt nitrate solution, impregnate at room temperature for 12 hours, and then dry at 100°C until the water evaporates completely to obtain an adsorbent precursor with a loading capacity of 2.5%. Put the precursor into the plasma at room temperature Nitrogen was introduced into the bulk reactor at a flow rate of 20 mL / min, and the discharge power was 20 W for 2 h to obtain a nano-scale ceria adsorbent with cobalt as the active center. The obtained adsorbent was subjected to simulated flue gas demercuration experiment. The effects of different hydrogen flow rates on the mercury removal efficiency of the adsorbent when dealing with oxygen defects are shown in Table 3.

[0028] Table 3 Effects...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com