Dialkyl phosphinate as well as preparation method and application thereof

A technology of dialkyl phosphinate and dialkyl phosphinic acid, which is applied in the field of dialkyl phosphinate and its preparation, and can solve problems such as agglomeration, large specific surface area, and low flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] like figure 1 As shown, the preparation method of dialkyl phosphinate according to one embodiment of the present invention includes the following steps S1-S2:

[0032] S1. Mix the metal salt solution, the mesoporous template agent and the alkali to carry out the metathesis reaction to obtain the template-loaded metal hydroxide. The specific surface area of the mesoporous template is 100m 2 / g~450m 2 / g, the pore diameter is 1nm~10nm.

[0033] S2. Neutralizing the dialkylphosphinic acid and the metal hydroxide supported on the template to obtain a dialkylphosphinic acid salt.

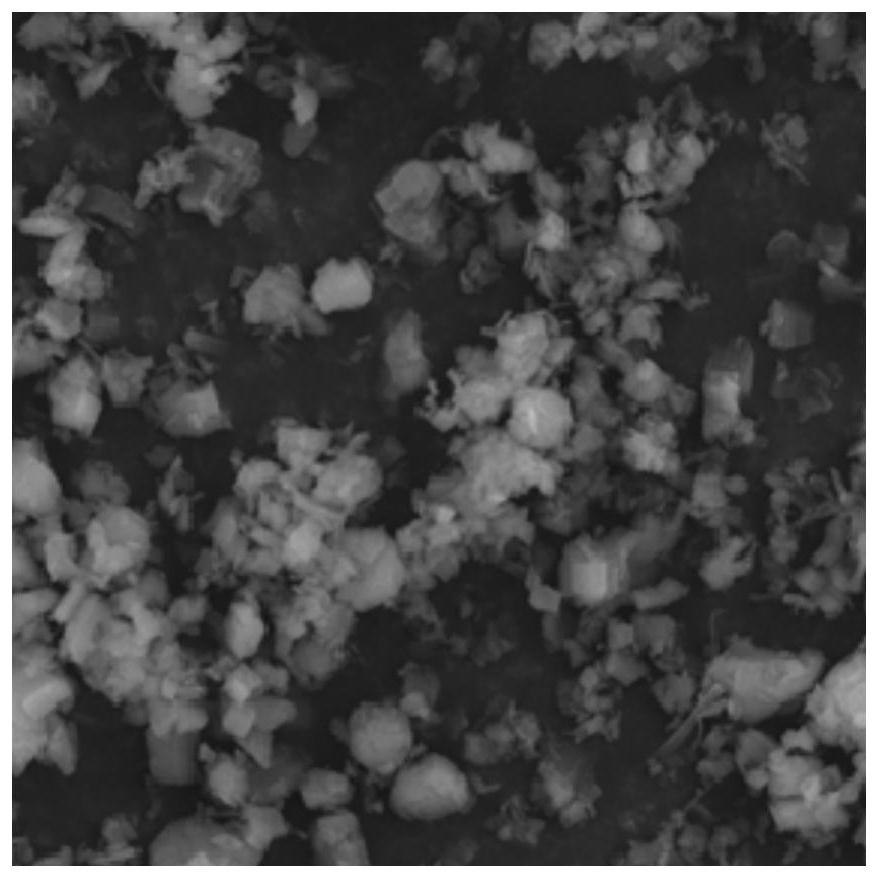

[0034] The traditional preparation method uses dialkyl phosphinate and metal salt for metathesis reaction. In this process, a large amount of inorganic salt by-products will inevitably be produced, which increases the processing cost, and there is a problem that the crystal particles cannot be controlled, which leads to subsequent When used, agglomeration and precipitation are prone to occur...

Embodiment 1

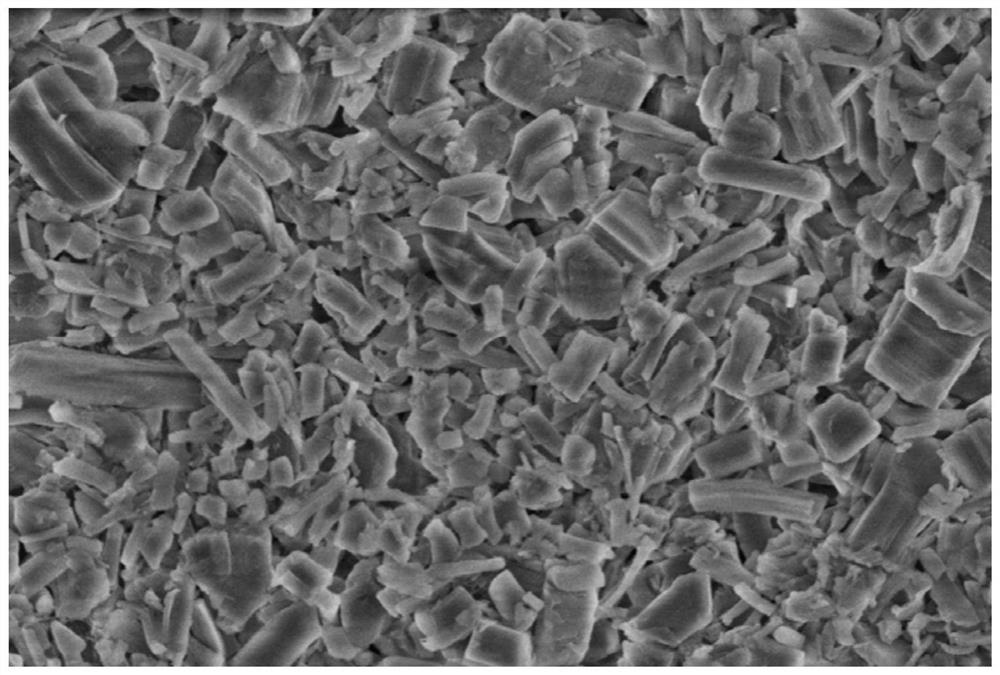

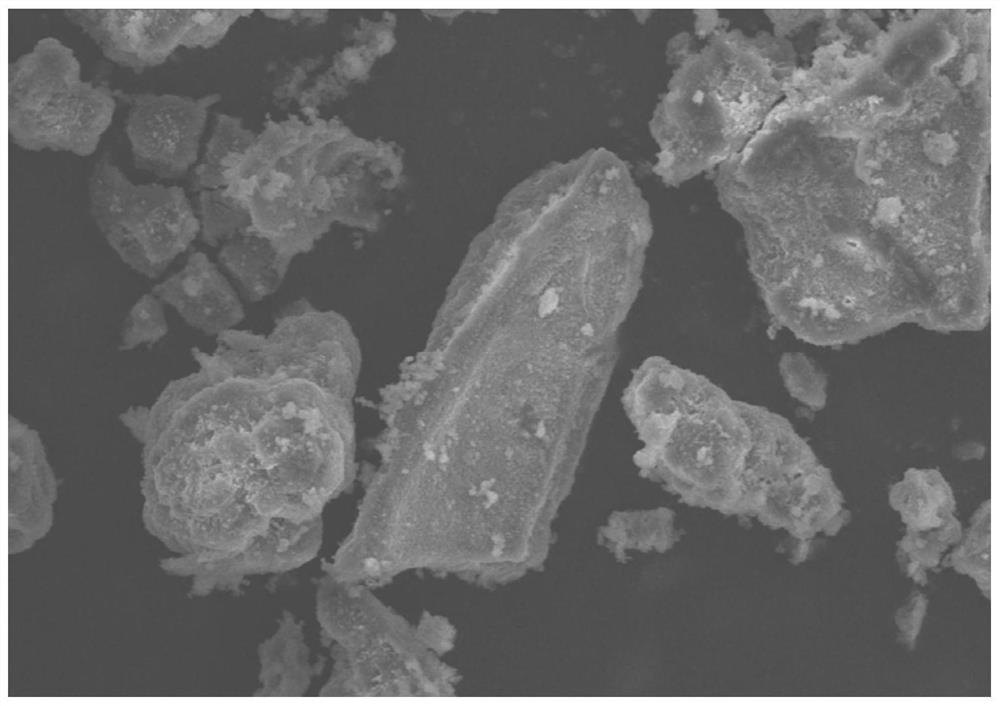

[0044] With 4440g 15wt% 18 water aluminum sulfate aqueous solution and 20g mesoporous alumina (mesoporous specific surface area is 150m 2 / g, the pore diameter is 2nm) in a 10L three-necked flask for rapid stirring and dispersing and heating up, at 65°C, 2400g of 10wt% sodium hydroxide solution was added dropwise for neutralization, and the solid product was filtered and washed with water. The obtained solid product was mixed with 2500g of 30wt% diethylphosphinic acid aqueous solution and reacted at 115°C and 0.5MPa for 2h to obtain fibrous rod-shaped aluminum diethylphosphinate, the product quality was 752g, and the micrograph was as follows: figure 1 and figure 2 shown.

Embodiment 2

[0046] With 2664g 25wt% 18 water aluminum sulfate aqueous solution and 25g mesoporous aluminum phosphite (mesoporous specific surface area is 450m 2 / g, pore diameter is 10nm) in a 10L three-necked flask, stir rapidly to disperse and heat up, add dropwise 2400g of 10wt% sodium hydroxide solution to neutralize at 65°C, and the solid product is filtered and washed with water. The obtained solid product was mixed with 2500 g of 30 wt % diethylphosphinic acid aqueous solution, and then reacted at 75° C. and 0.1 MPa for 3 hours to obtain fibrous rod-shaped aluminum diethylphosphinate with a product quality of 734 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com