High performance liquid phase continuous automatic production and co-production technology of organic phosphine compound

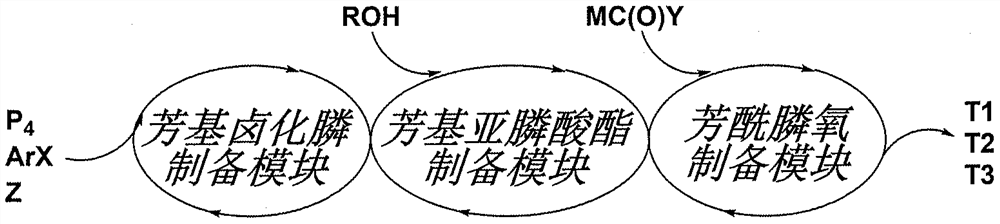

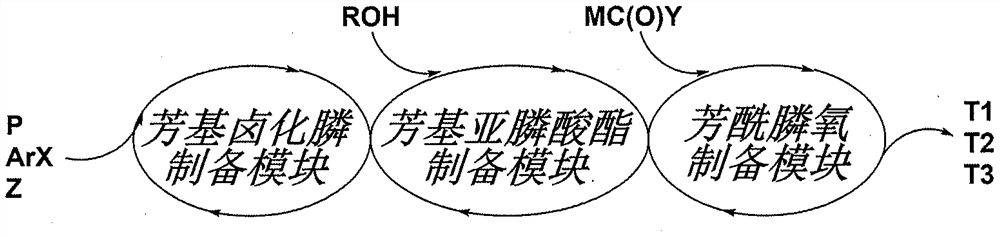

A high-efficiency liquid phase and compound technology, which is applied in organic chemistry, bulk chemical production, and compounds of Group 5/15 elements of the periodic table, etc., can solve problems such as high cost, unrealized continuous automatic production, and environmental protection and hazardous waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

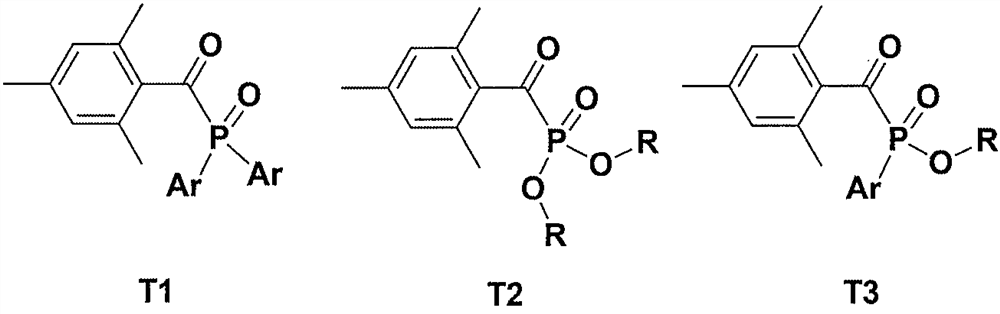

[0070]Example 1: High performance liquid phase flow line continuous automation production TPO

[0071][Aryl halide phosphine section] Under nitrogen protection, 66 kilograms of yellow phosphorus is placed in a pressure-resistant reactor, and 375 kg of chlorobenzene and 190 kg phenyl dichloride, mixture itself is sequentially added from the automatic metering infusion tank. When the pressure conditions were heated to 340-360 degrees Celsius for 4 hours, the reaction system was cooled to room temperature, and the liquid phase mixture was directly automatically input, and the hierarchical distillation device was opened, and the distillation was first distilled at normal pressure to obtain about 90 kg of chlorobenzene and three. The mixture of phosphorus chloride (used), and the restriction remissions were collected in sequentially collected from 235 kg of phenylphrachlorphrachloride (recovery) and 233 kg of diphenylphosphine. [Arylylphosphonate section] Under nitrogen protection, the 233 ...

Embodiment 2

[0072]Example 2: High performance liquid phase flow line continuous automation production TPO

[0073]The step of repeating the first example, but using an equal amount of 66 kg of grinding red phosphorus instead of the yellow phosphorus, heating is left in a aryl halide phosphine process to 390 degrees Celsius. After the streamlined process is completed, the TPO finished product is approximately 289 kg.

Embodiment 3

[0074]Example 3: High-performance liquid phase flow line continuous automation production TPO

[0075][Aryl halide phosphine section] Under nitrogen protection, 65 kilograms of yellow phosphorus is placed in a pressure-resistant reaction kettle, and 370 kg of chlorobenzene and 48 kg diphenyl phosphine are sequentially added from the automatic metering infusion tank. The mixture is closed itself. After the pressure conditions were heated to 370-395 degrees Celsius for 6 hours, the reaction system was cooled to room temperature, and the liquid phase mixture was directly automatically input to the distillation, and the hierarchical distillation device was opened, and the chlorobenzene and trichloride were first evaporated under normal pressure. The mixture of phosphorus (recovered), and the restriction rectification is sequentially collected to obtain 201 kg phenyl dichloride (recovery) and 242 kg of diphenylphosphine. [Aryl phenylphosphonate section] Under nitrogen protection, the 242 kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com