Low-odor low-volatility polyvinyl chloride material and preparation method thereof

A polyvinyl chloride, low-volatility technology, applied in the field of low-odor and low-volatility polyvinyl chloride materials and preparations, can solve the problems of high cost and easy precipitation, and achieve the effect of stable quality, uniform color and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation of a low-odor and low-volatility polyvinyl chloride material comprises the following steps:

[0022] (1) Preparation of epoxidized soybean oil: react epoxidized soybean oil, acrylic acid, and tetramethylammonium chloride at 120° C. for 60 minutes in a mass ratio of 60:30:0.5;

[0023] (2) Preparation of heat stabilizer: calcium stearate and zinc stearate are mixed by mass ratio 50:50;

[0024] (3) Preparation of low-odor and low-volatility polyvinyl chloride material, PVC resin powder and epoxidized soybean oil are placed in the mixer and stirred and mixed for 20min, then add environment-friendly plasticizer, heat stabilizer, lubricant and deodorant, Raise the temperature to 120°C, stir and react for 3 hours, and then put it into a twin-screw extruder at a temperature of 150°C for extrusion, granulation and molding.

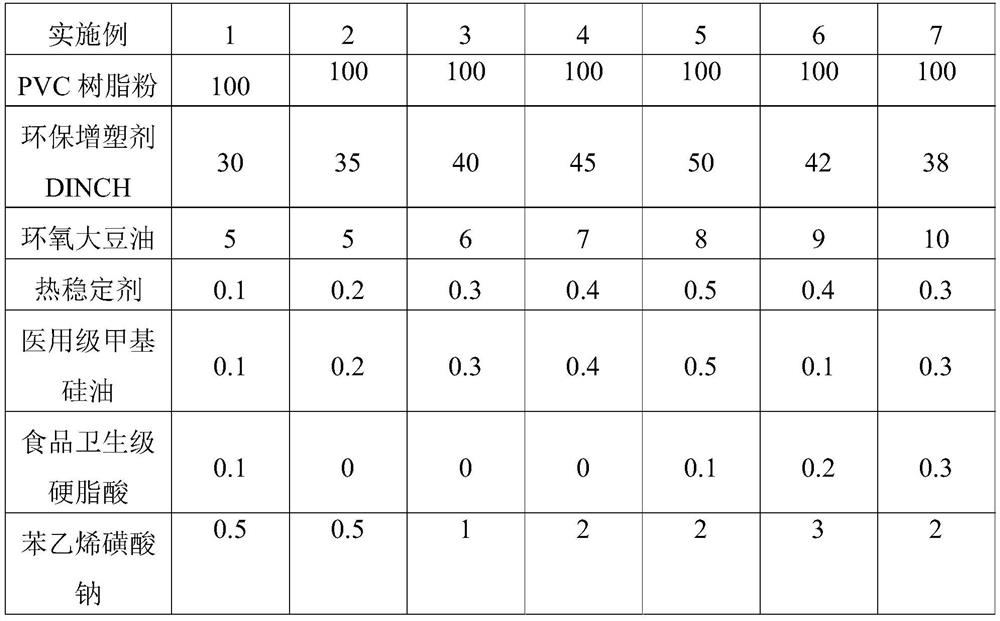

Embodiment 1-7

[0026] The parts by weight of the raw materials used in each embodiment are shown in Table 1 below:

[0027] Table 1, the amount of each component is in kg

[0028]

[0029]

Embodiment 8

[0036] The preparation of a low-odor and low-volatility polyvinyl chloride material comprises the following steps:

[0037] (1) Preparation of epoxidized soybean oil: react epoxidized soybean oil, acrylic acid, and tetramethylammonium chloride at 110° C. for 120 minutes in a mass ratio of 60:20:0.1;

[0038] (2) preparation of heat stabilizer: calcium stearate and zinc stearate are mixed by mass ratio 60:40;

[0039] (3) Preparation of low-odor and low-volatility polyvinyl chloride material, put 100 parts of PVC resin powder and 5 parts of epoxy soybean oil into the mixer and mix for 10 minutes, then add 30 parts of environmentally friendly plasticizer DINCH and 0.1 part of heat stabilizer , Lubricant food hygiene grade stearic acid 0.2 and deodorant sodium styrene sulfonate 0.5 part, heat up to 100°C, stir for 2 hours, then put into twin-screw extruder, extrude at 130°C, granulate and shape .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com